Synchronous construction method for shield method tunnel

A technology of simultaneous construction and shield method, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of small transportation volume, increased construction period, single transportation route, etc., and achieve the effect of achieving high speed and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

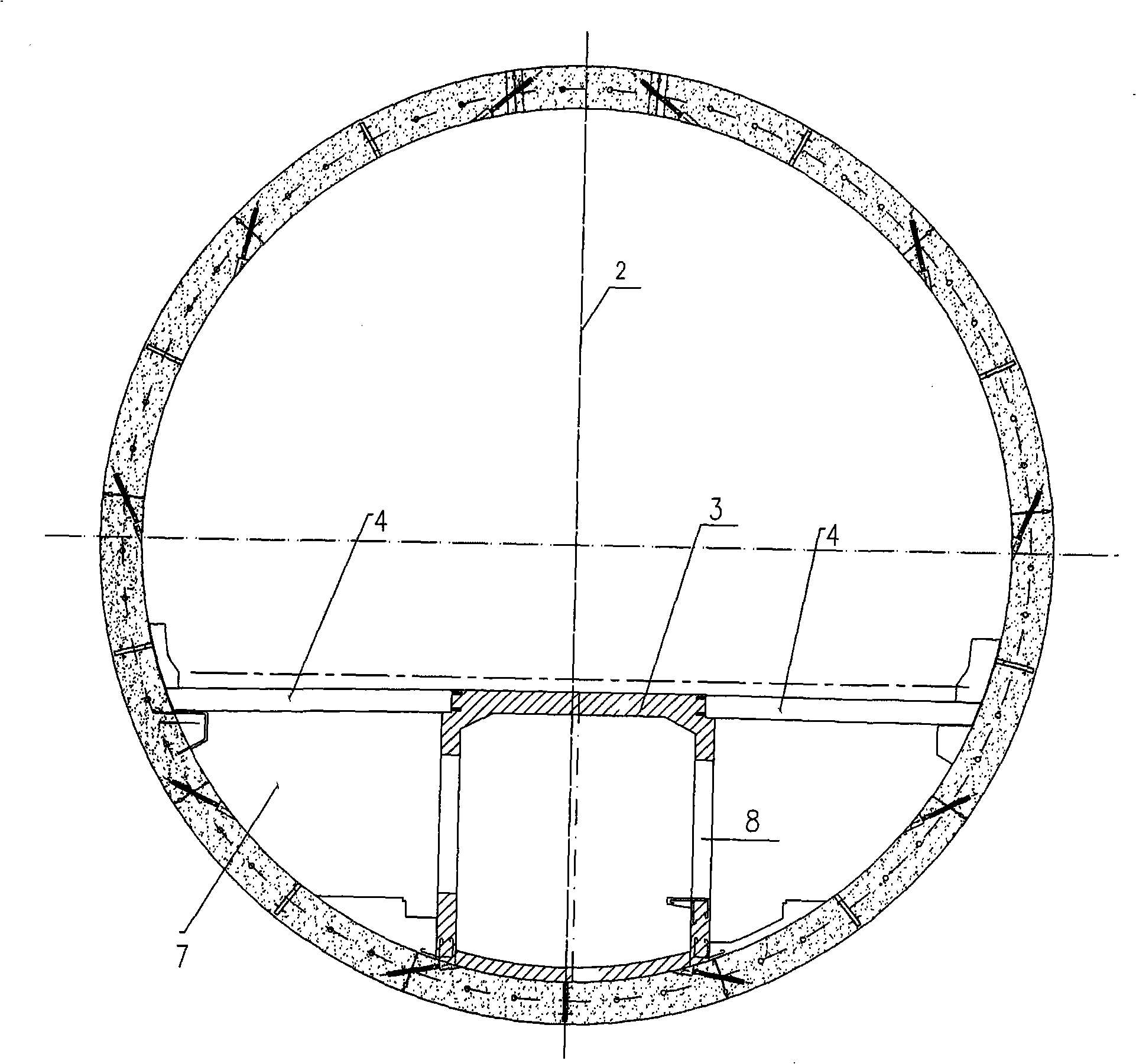

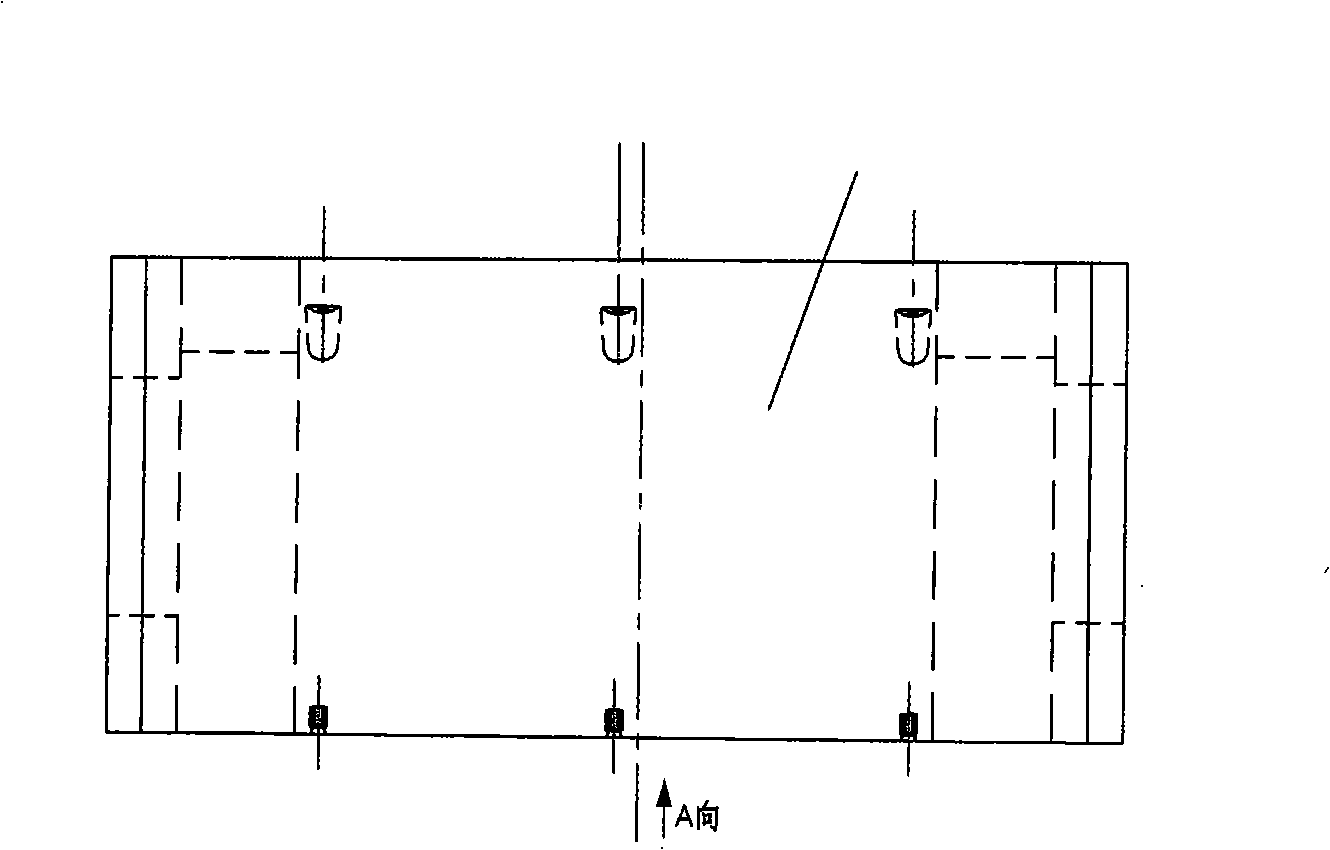

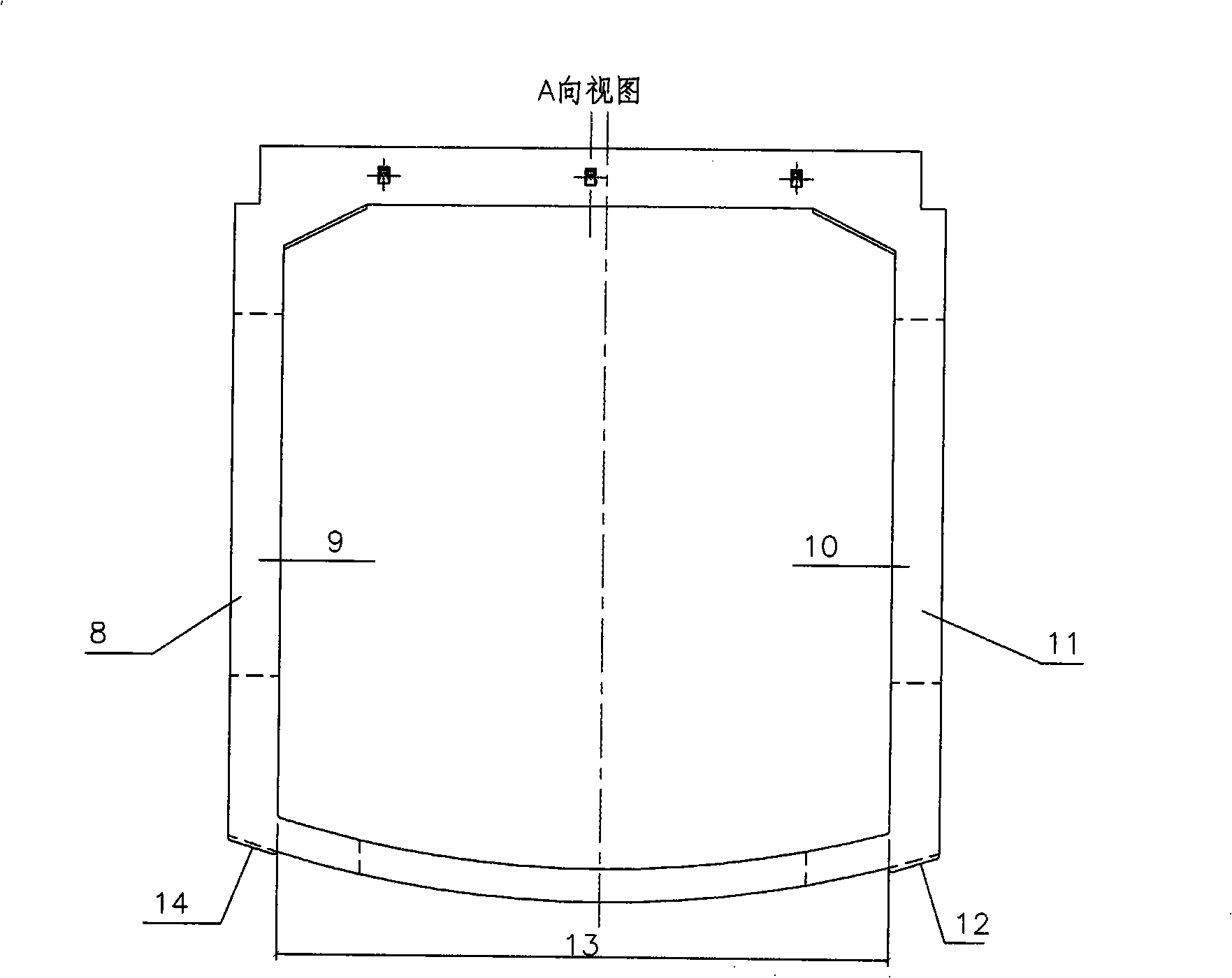

[0020] Such as Figure 1-5 As shown, the method of this embodiment adopts the following steps:

[0021] Firstly, prefabricated square-shaped prefabricated components 3, the length of each section of square-shaped prefabricated components 3 is equal to the segment ring width of the tunnel lining ring 1, and according to the requirements of the curve radius of the line, it is set into standard blocks and wedge-shaped blocks.

[0022] Then inside the lining ring 1, along with the advancement of the shield tunneling, a square-shaped prefabricated component 3 is placed sequentially at a certain distance behind the shield tail. 4 connections. The height of the tongue and groove is taken as the thickness of the cast-in-place slab 4, and the width is ≥150mm, and a steel connector is reserved to ensure that the top plate 5 of the prefabricated component 3 and the cast-in-place slab 4 form a continuous slab with stable stress.

[0023] The joints of the square-shaped prefabricated com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com