Pressure balance type temperature control bellow element

A balanced, membrane box technology, applied in the direction of temperature control without auxiliary power supply, can solve the problems of short service life and unstable working performance, and achieve the effect of long service life and stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

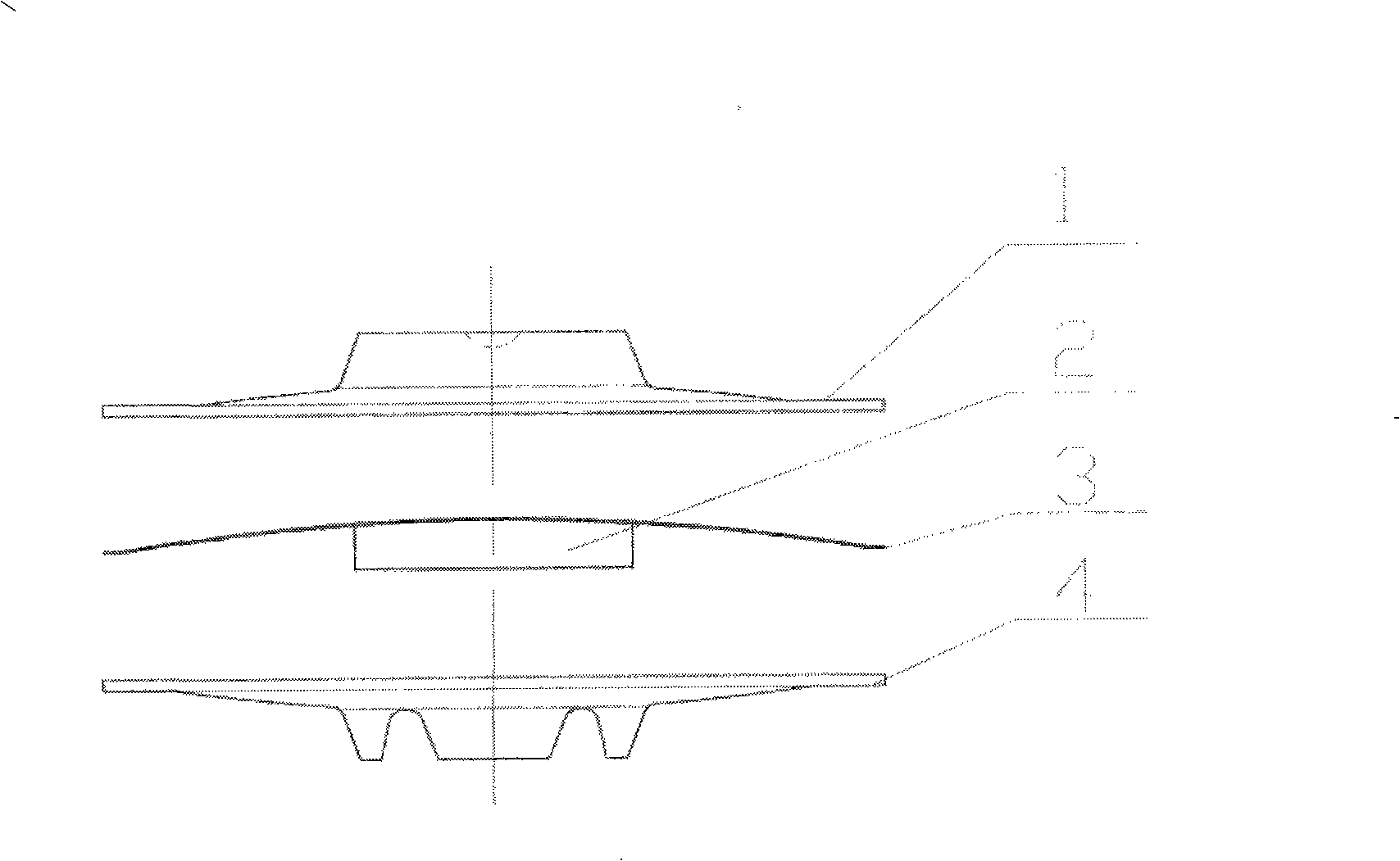

[0012] like figure 1 Shown, the present invention is mainly made up of upper diaphragm (1), sealing sheet (2), middle diaphragm, lower diaphragm (4) airtight welding, wherein upper diaphragm (1), middle diaphragm (3) and lower The diaphragm (4) is directly formed by stamping, the sealing sheet (2) is fixed on the middle diaphragm (3), and the formula liquid is sealed and stored between the upper diaphragm (1) and the middle diaphragm (3). When the external temperature reaches the boiling point of the temperature-sensing liquid, the temperature of the formula liquid between the upper diaphragm (1) and the middle diaphragm (3) begins to rise, the liquid gradually volatilizes and turns into a gas, the volume expands, and the pressure begins to increase. The diaphragm (3) moves outward. When the temperature reaches saturation, the liquid in the diaphragm b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com