Stair type heat radiator of heat radiating fins

A stepped radiator and heat sink technology, applied in the field of transformer accessories, can solve the problems of transformer working influence, transformer burnt, large oil volume, etc., and achieve the effects of uniform shunt, material saving, and heat dissipation balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

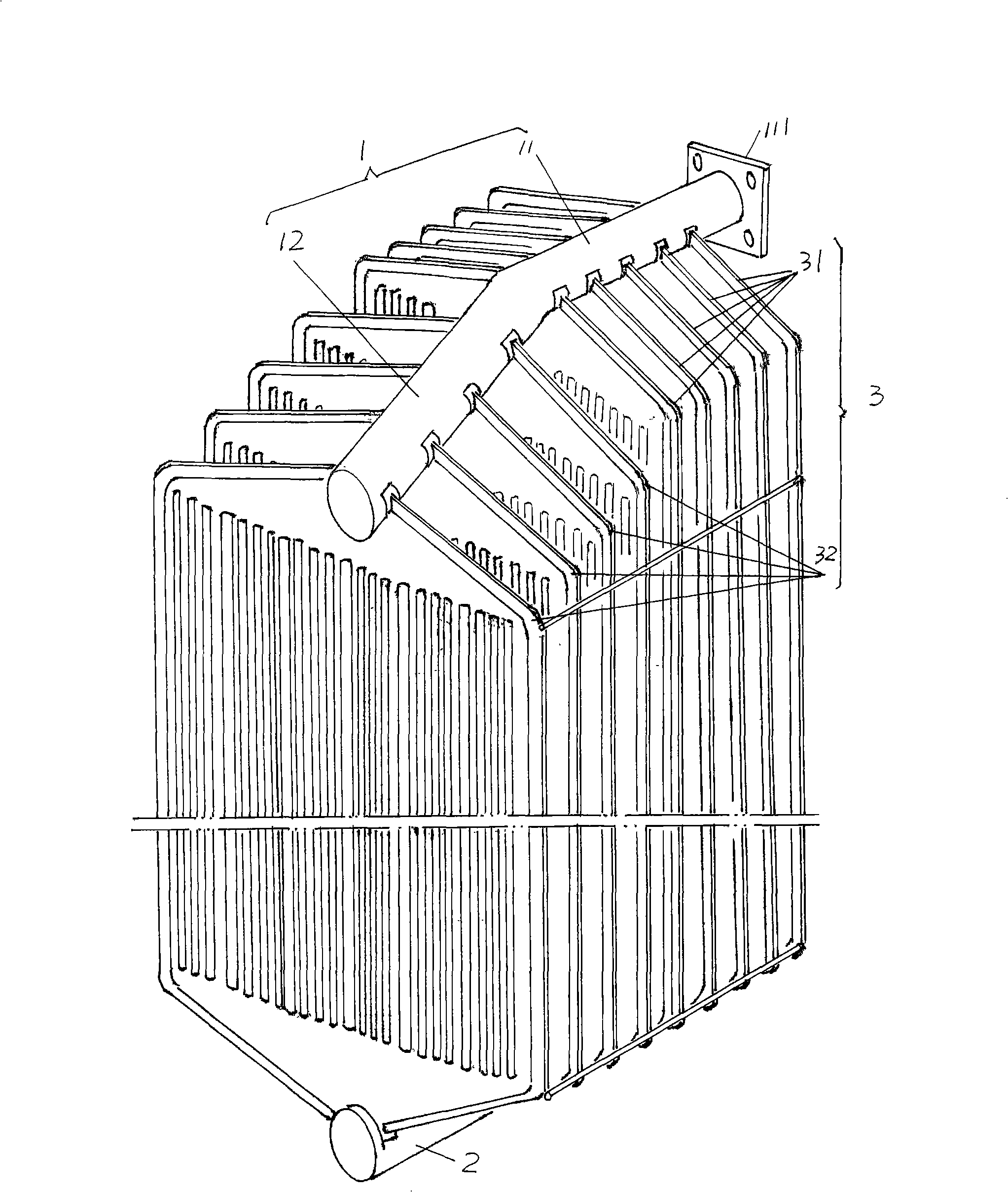

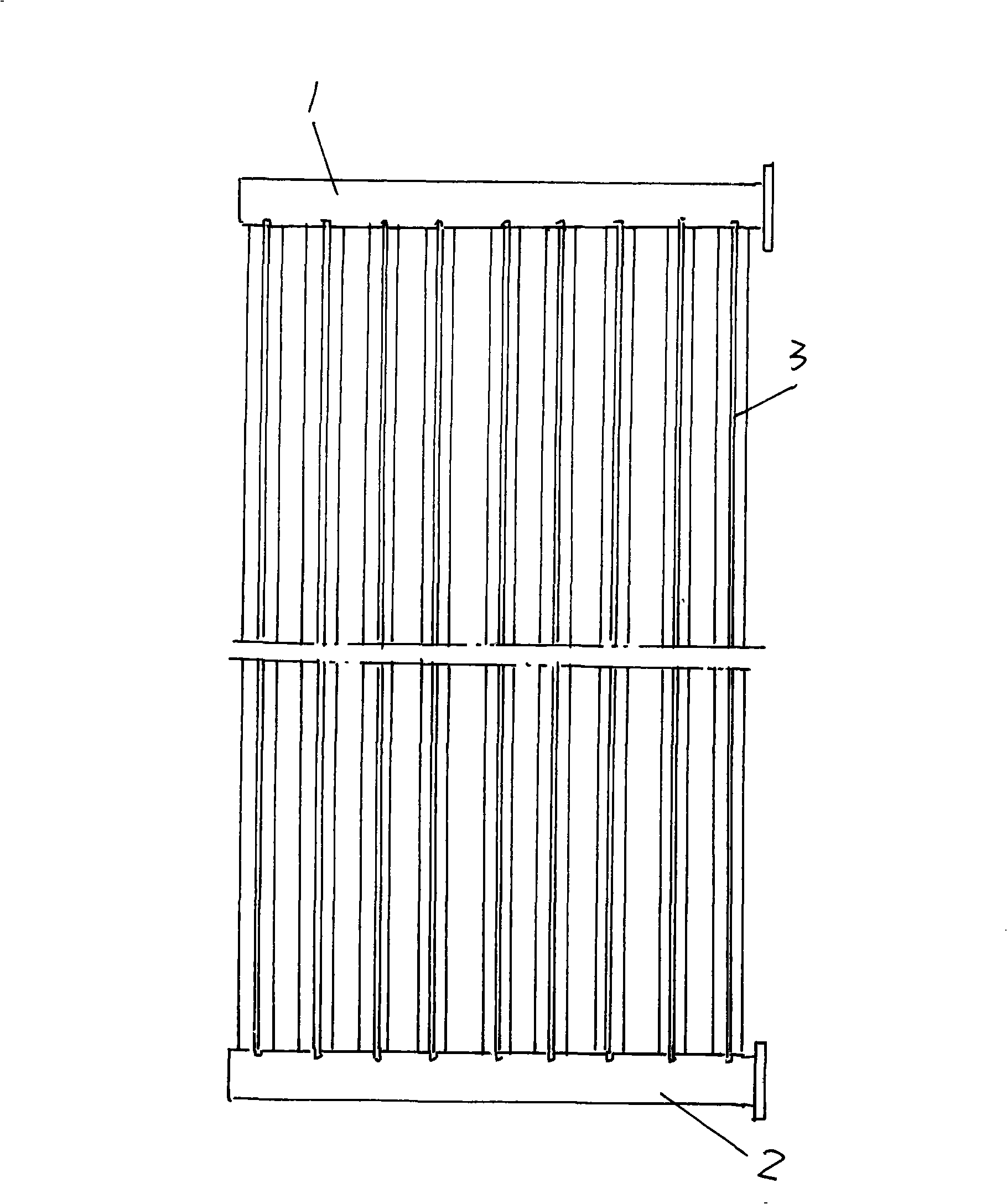

[0017] please see figure 1 , shows a stepped radiator with cooling fins, which includes an oil inlet pipe 1, an oil return pipe 2, and a set of cooling fins 3 connected between the oil inlet and oil return pipes 1 and 2. The oil inlet pipe 1 includes a horizontal pipe section 11 and an inclined pipe section 12. Taking the current illustrated position as an example, the right end is a horizontal pipe section 11, and the left end is an inclined pipe section 12. The inclined pipe section 12 is formed by bending on the horizontal pipe section 11, that is, the horizontal pipe section 11 It is the same pipe as the inclined pipe section 12, only the shape has changed. The concept of the horizontal pipe section 11 mentioned above refers to a pipe section that is horizontal in use. The left end port of the horizontal pipe section 11 is the oil inlet 111. Pipe section 11 is taken up, then by inclined pipe section 12. If the oil inlet pipe 1 is processed into a long circular pipe as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com