Method of manufacturing a semiconductor device

A semiconductor and device technology, applied in the field of manufacturing semiconductor devices, to achieve the effect of increasing mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

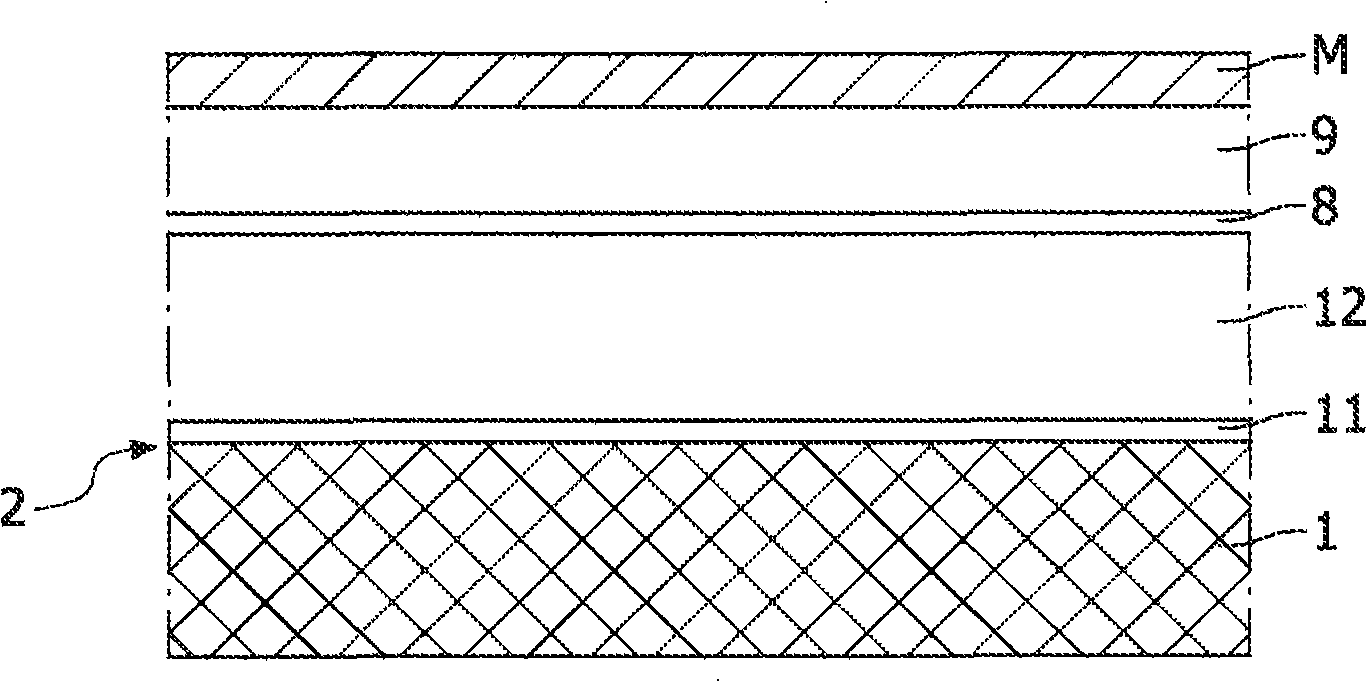

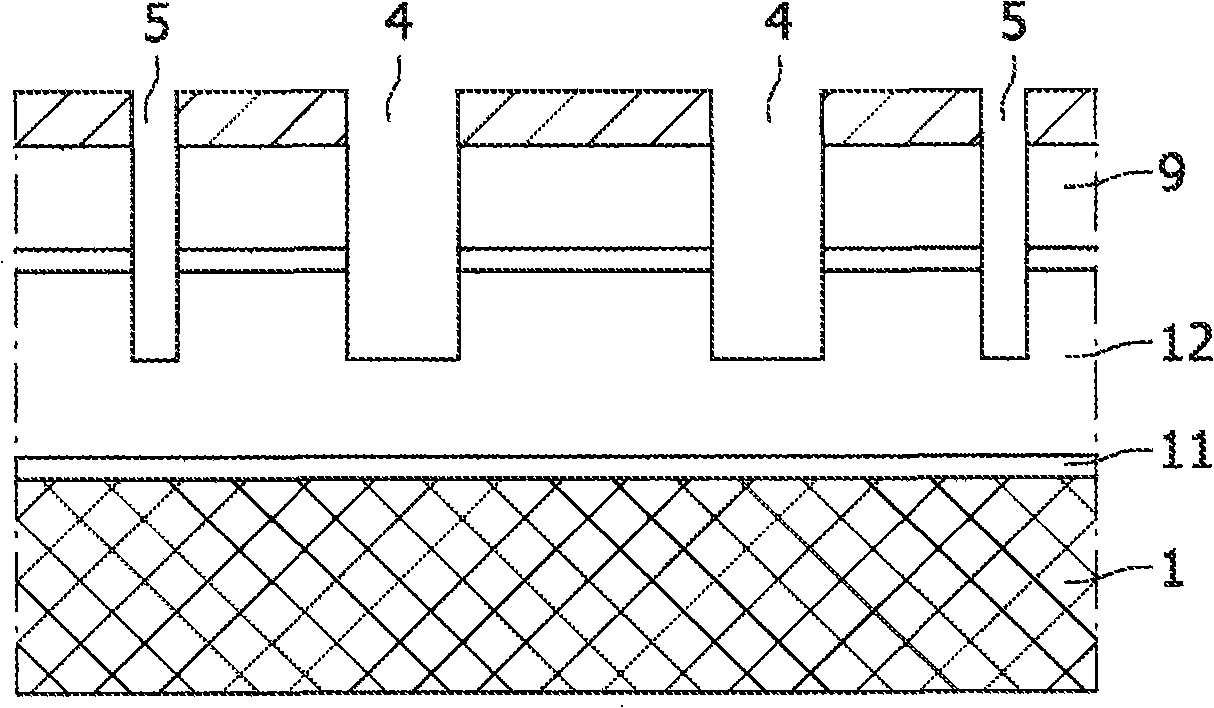

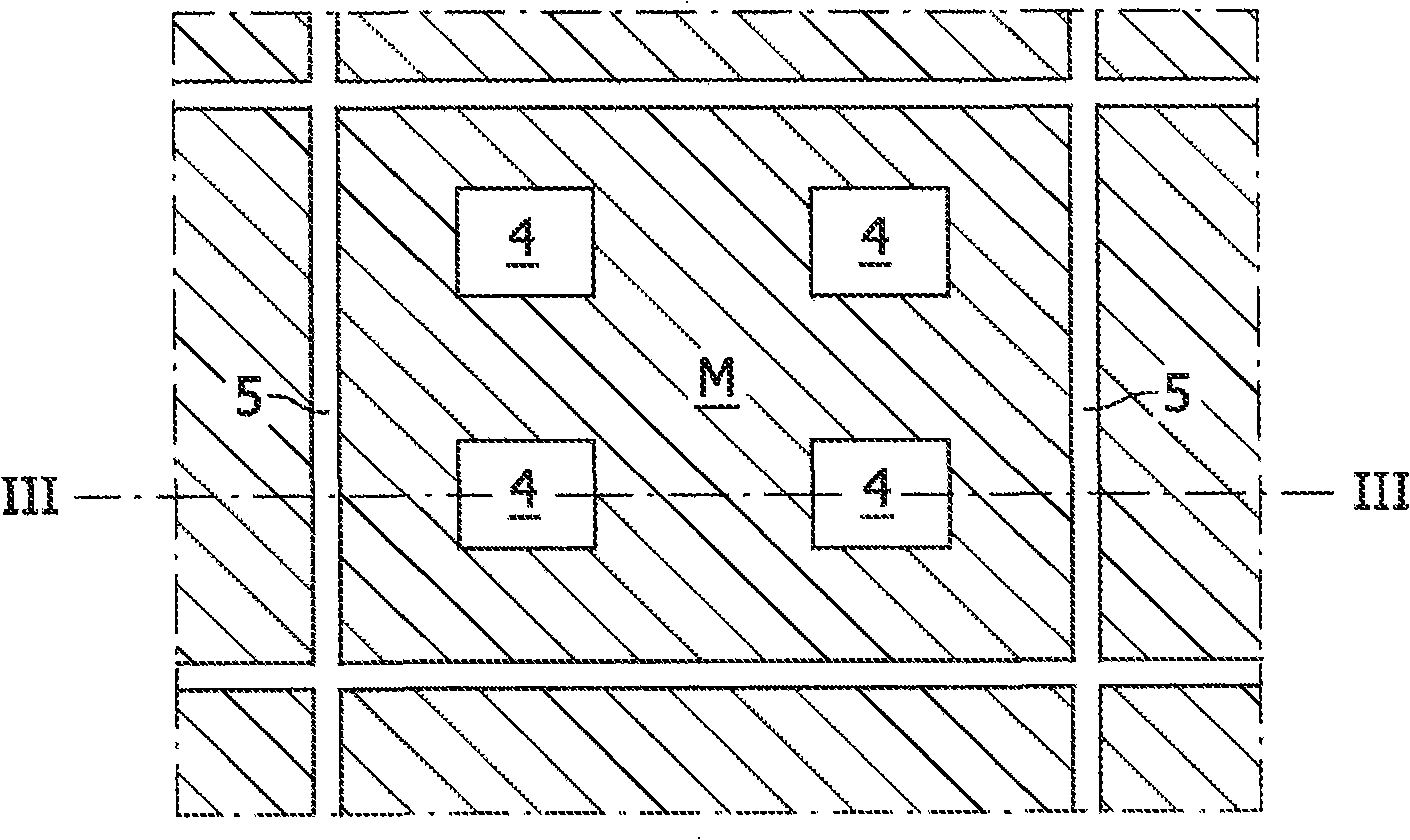

[0037] The first embodiment of the invention shares some of the original process steps of WO-2005 / 093824, so initially reference will be made to Figure 1A , 1B and 1C to describe the first embodiment of the present invention. As used in the method disclosed in WO-2005 / 093824, the method of the present invention uses selective etching to etch the sacrificial layer between the semiconductor film and the bulk substrate. Such as Figure 1A As shown, a layered or stacked structure is formed, and the layered structure includes a substrate 1 , a lower etch stop layer 11 , a sacrificial layer 12 , an upper etch stop layer 8 and a semiconductor layer 9 sequentially from bottom to top. In this example, bulk substrate 1 is a semiconductor substrate of silicon. On this substrate, a SiGe epitaxial layer 11 is grown, with a thickness ranging from 1 to 50 nm, and serving as a lower etch stop layer. The germanium content of this layer 11 is between 10 and 30 at.%. Then, a silicon epitaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com