Porcelain granule sand granulator

A technology of pelletizing machine and ceramsite sand, which is applied in the methods of granulating raw materials, chemical instruments and methods, chemical/physical processes, etc., to achieve shortened granulation process, less equipment and area, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

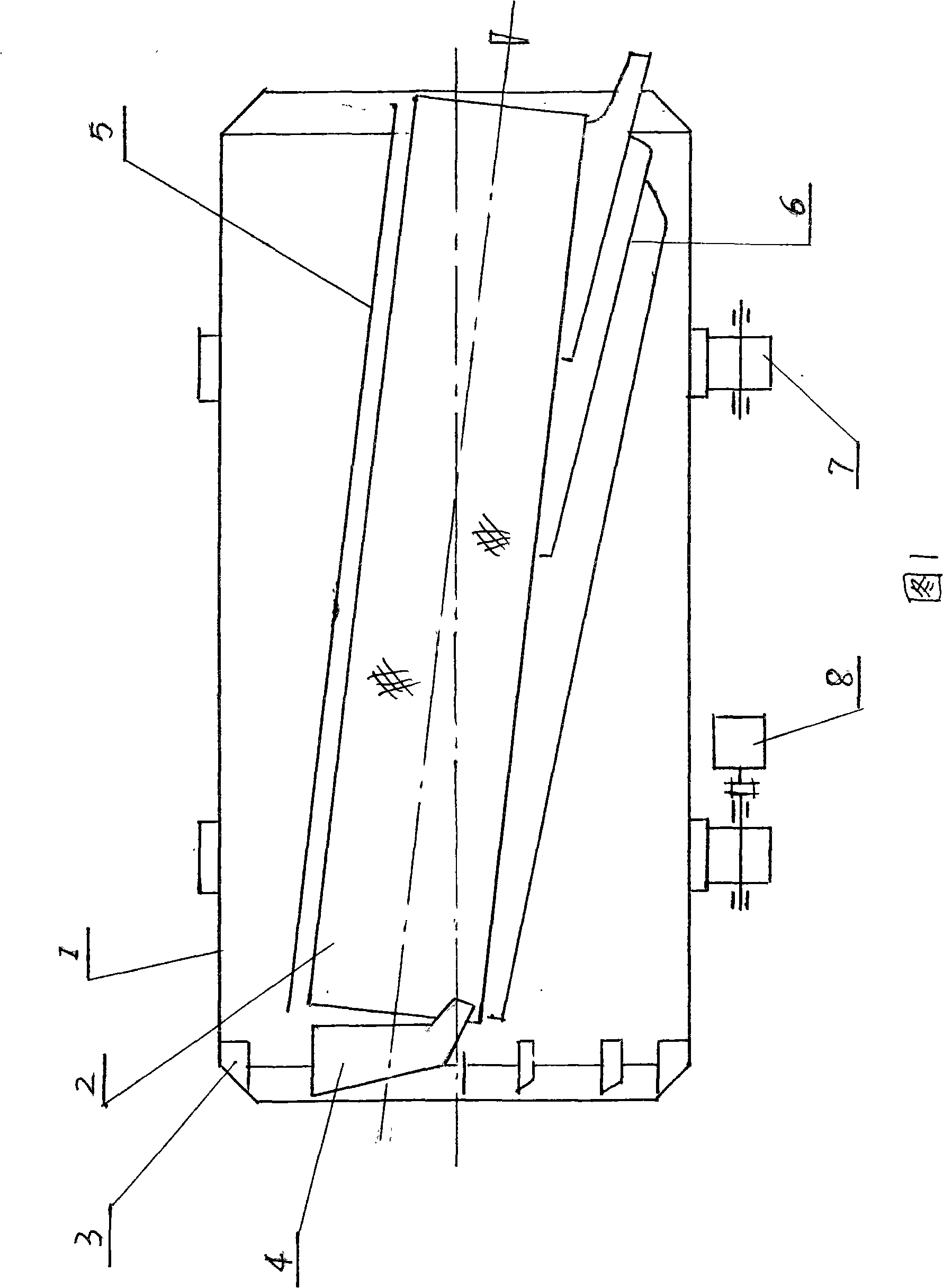

[0009] In Fig. 1, the granulation drum 1 is in the shape of a garden, and its two ends are welded with lifting plates 3. The axis of the granulation drum 1 is inclined at a certain angle to the horizontal line, and is supported and fixed by the supporting roller 7. When rotating, it is rotated by the rotating device 8. Dragging; trommel 2 is a cylindrical frame with a shaft in the center and a screen on the outside. It is installed in the granulation drum 1, and the bearings at both ends are fixed by the brackets outside the granulation drum 1. The trommel 2 A shielding cover 5 is fixed outside, and a grading plate 6 is installed under it. The trommel 2 has a trommel hopper 4 at the high end, and a lifting plate 3 is welded inside the granulation drum 1 at the same end. The axis of the trommel 2 is also inclined at a certain angle to the horizontal line. But the inclination angle of the axis of the granulation drum 1 is opposite.

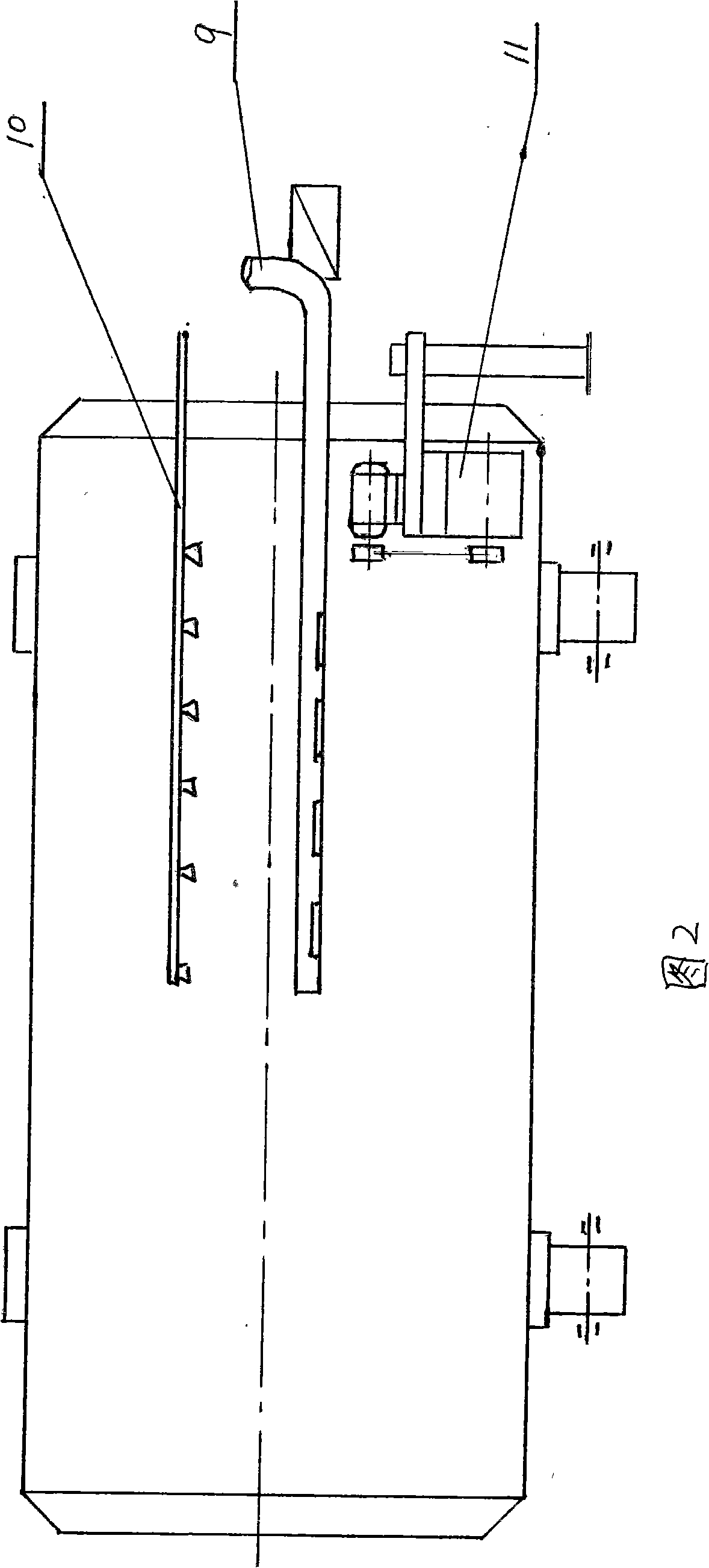

[0010] In Figure 2, the front part of the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com