Filling material duty cycle operation method for auxiliary sludge dewatering

A technology for sludge dehydration and sludge, applied in separation methods, chemical instruments and methods, filtration and separation, etc., to achieve the effects of improving compression resistance, easier guarantee of supply, high economy and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

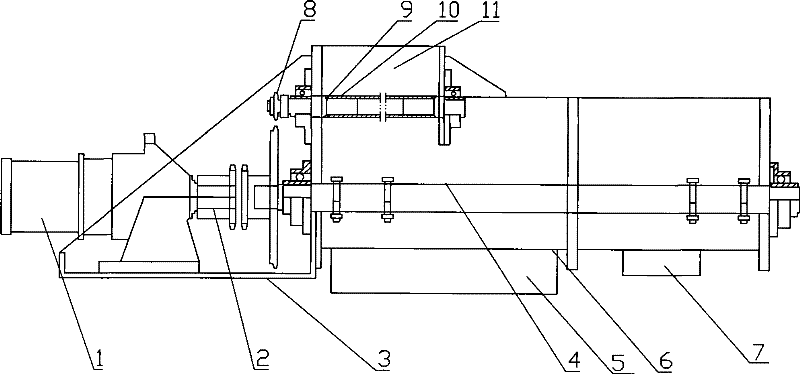

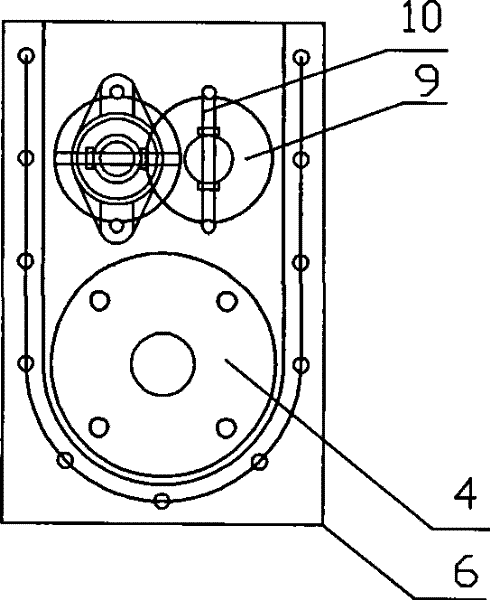

[0020] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

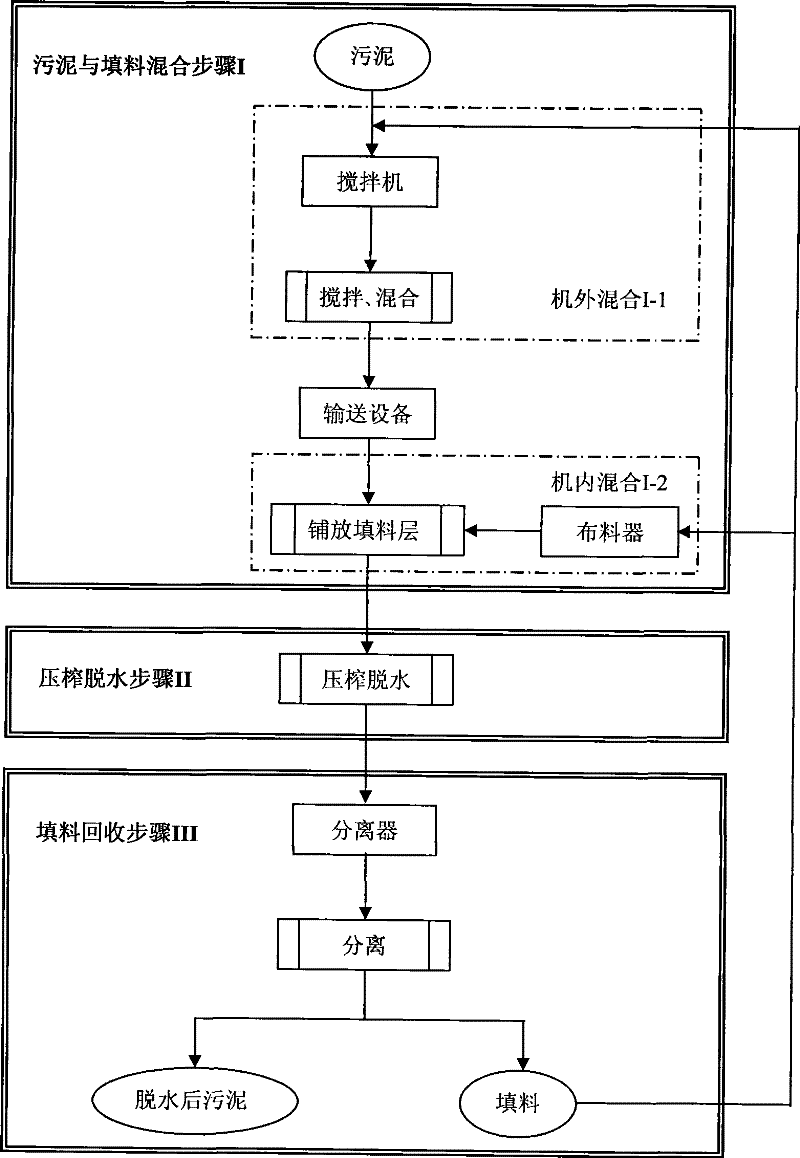

[0021] see figure 1 , Example The process flow of the filler recycling method for assisting sludge dewatering includes filler and sludge mixing step I, pressing dehydration step II and filler recovery step III.

[0022] Filler and sludge mixing step I adopts two mixing methods: external mixing I-1 and internal mixing I-2. After concentration and dehydration, the sludge with a water content of 70-85% is mixed with a sludge weight of 2-2 50% filler, the amount of filler mixed depends on the sludge composition and water content control and adjustment. The filler is a solid material in the form of strips or granules or lumps or rounds, or inelastic or elastic materials that are knotted and bonded together. The inelastic material can be a plastic sheet, and the elastic material can be a knotted filter cloth. Or rubber or sponge. The filler materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com