Novel steel braced girder composite structure

A composite structure and steel truss girder technology, which is applied to bridges, truss bridges, bridge parts, etc., can solve the problems of structural stress and unreasonable use, unreasonable span layout, and prone to negative reaction forces on supports. Achieve the effect of easy procurement, high rigidity and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In the present invention, steel-concrete composite bridge deck segments 2 may also be arranged in the middle span of the main truss 1 as required, and full steel beam structure segments may be arranged in the side span of the main truss 1 in the middle span as required. 3.

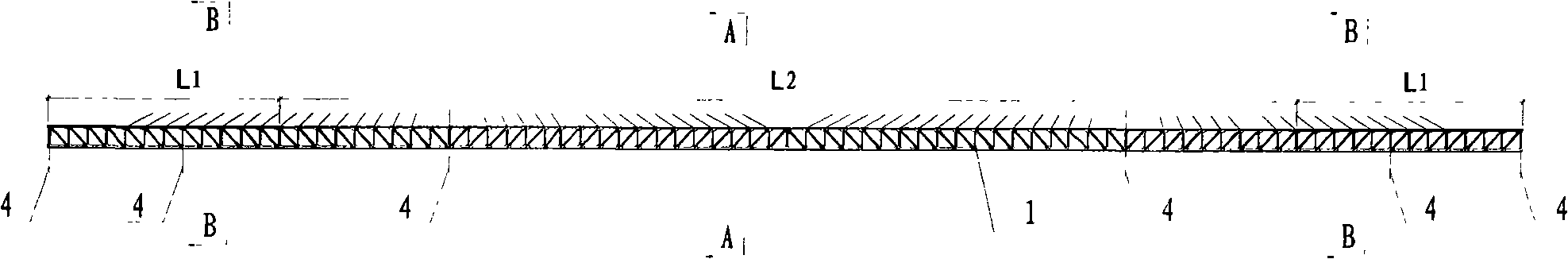

[0011] refer to figure 1 , the main truss 1 of the present invention has 6 piers 4 in total, the steel-concrete deck segment 2 is arranged at the side span length L1=168 meters, and the all-steel truss segment 3 is arranged at the mid-span length L2=756 meters.

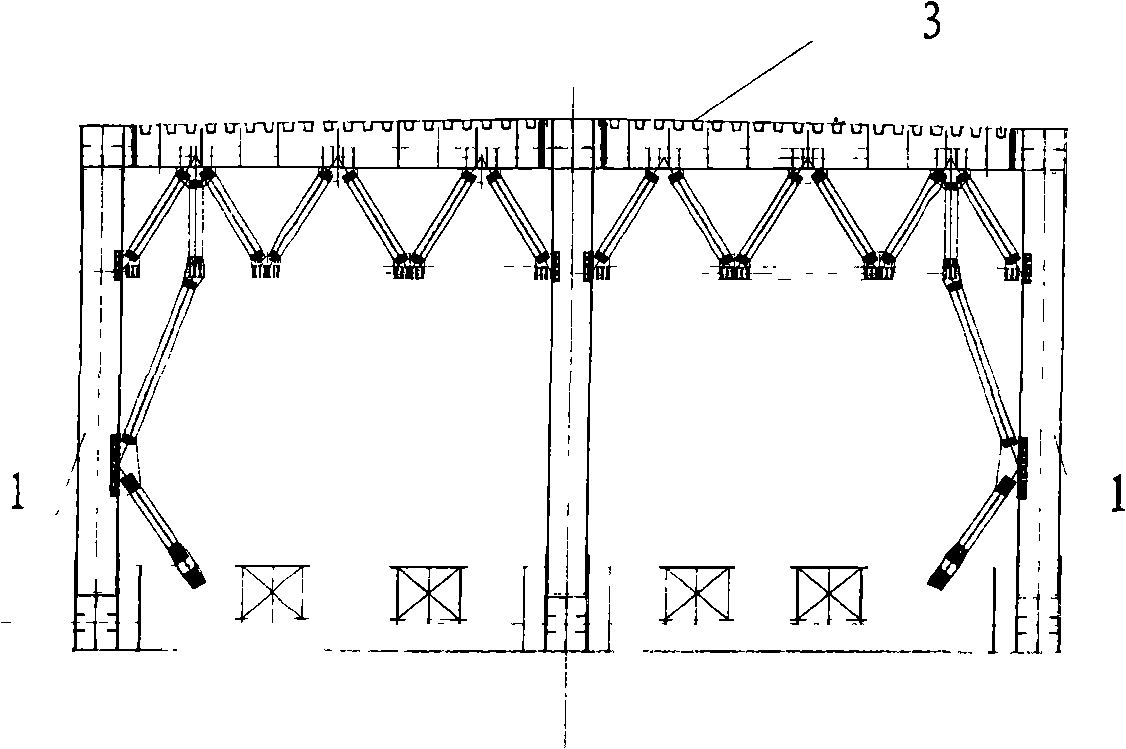

[0012] figure 2 It is the standard cross-section of the all-steel truss segment 3 arranged within the mid-span L2 of the main truss 1.

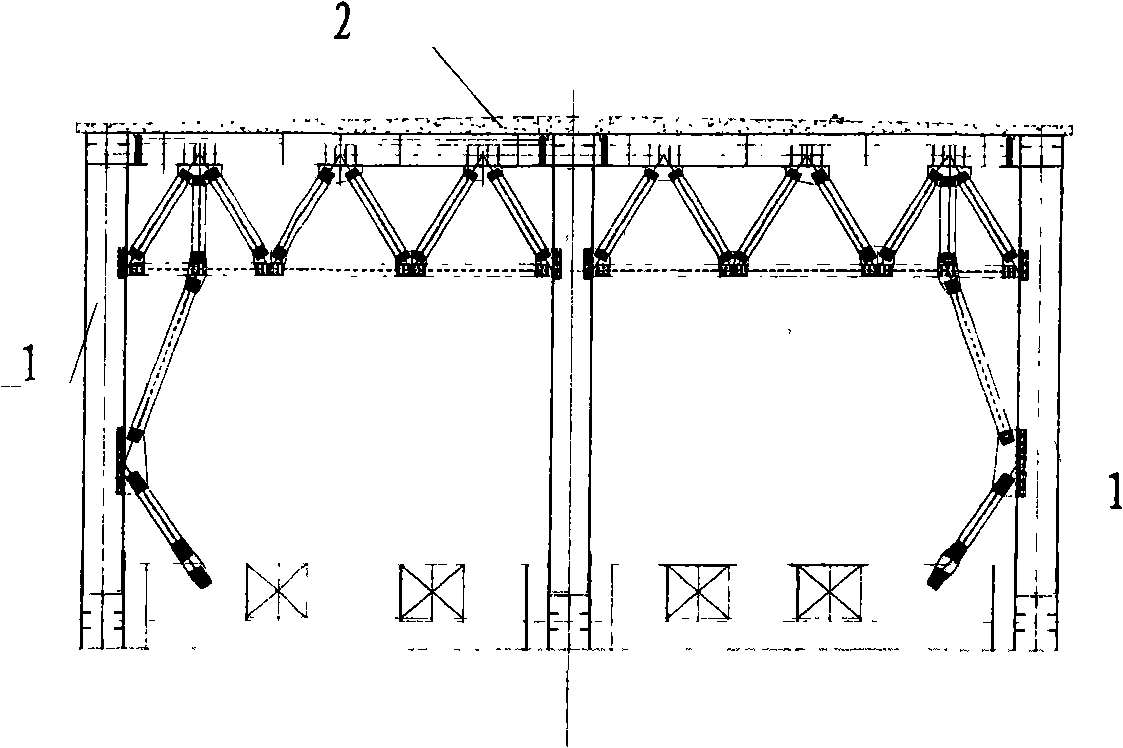

[0013] image 3 It is the standard cross-section of the steel-concrete deck segment 2 arranged within the range of the side span L1 of the main truss 1.

[0014] The present invention adopts all-steel truss girder segments in the section where self-weight needs to be reduced, and uses steel-concrete c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com