Dislocation assembly network frame hoisting construction method and its hoisting system

A construction method and network frame technology, which are applied in transportation and packaging, load hanging components, construction, etc., can solve the problems of poor stress on the pole, high hoisting height, and heavy weight, so as to reduce construction difficulty and improve safety Sexuality and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described

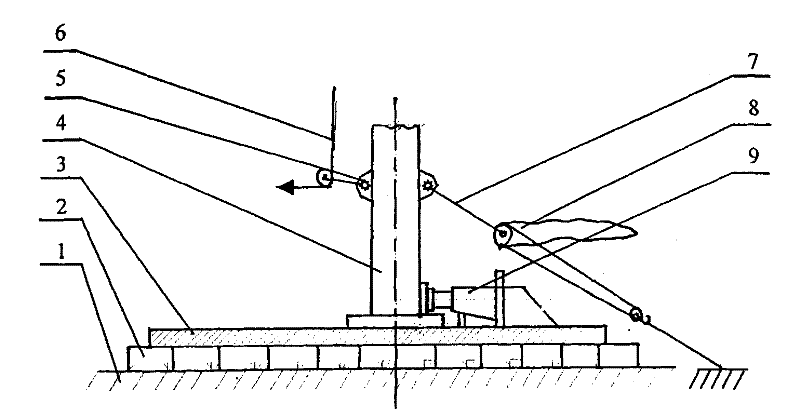

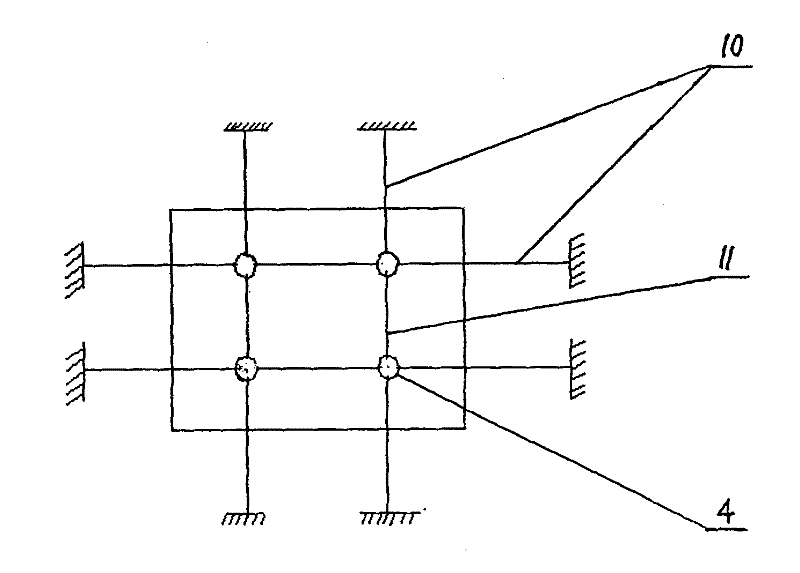

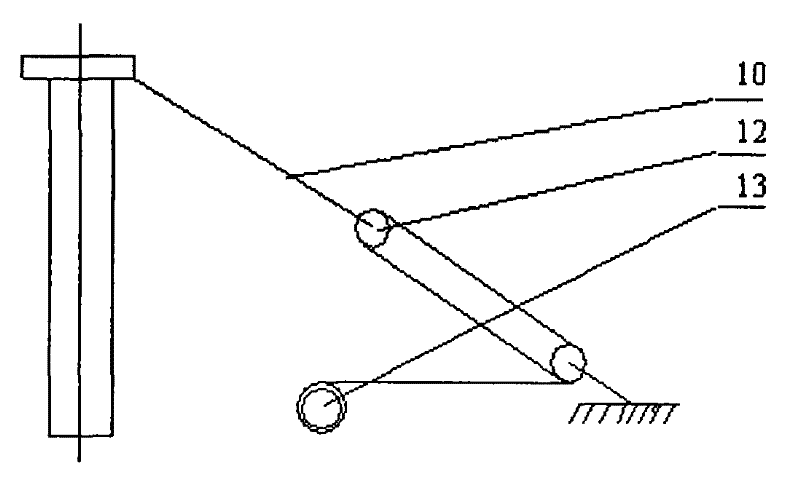

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown, the hoisting system of the present invention's misplaced assembling grid hoisting construction method is made up of four poles (4), and each pole is provided with lug plate 5, running rope 6, hoisting tackle (not shown) according to the prior art on each pole. Figure) and hoist (not shown) grid hoisting mechanism composed of. The pole-holding base is placed on the supporting steel plate 3 . The lower part of each pole is equipped with a displacement walking device 9 and a foot-sealing rope 7, and the foot-sealing rope 7 is connected to the ground anchor through a chain 8. Two pull ropes 10 are arranged on the top of each pole, and each pull rope 10 is respectively connected to the winch 13 through anchor blocks 12; connecting ropes 11 are connected between the tops of the poles, and the connecting rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com