Underwater orthogonal swinging type neutral cable synchronous conveying mechanism

A technology of conveying mechanism and neutral cable, which is applied in the field of synchronous conveying mechanism for retracting and unwinding the neutral cable, which can solve the problems of limited conveying force, large space, and large size of steering wheels, etc., to ensure accuracy and synchronization, and easy system integration , the effect of small swing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

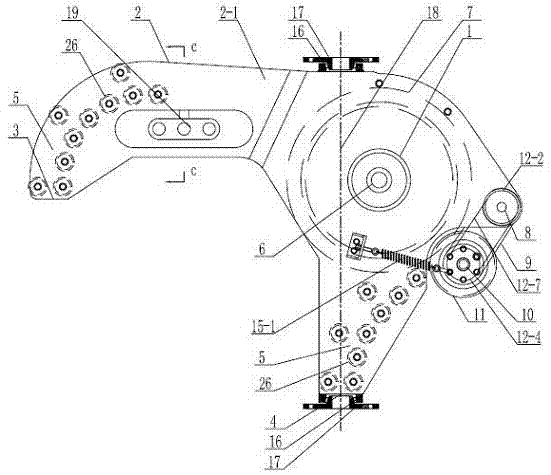

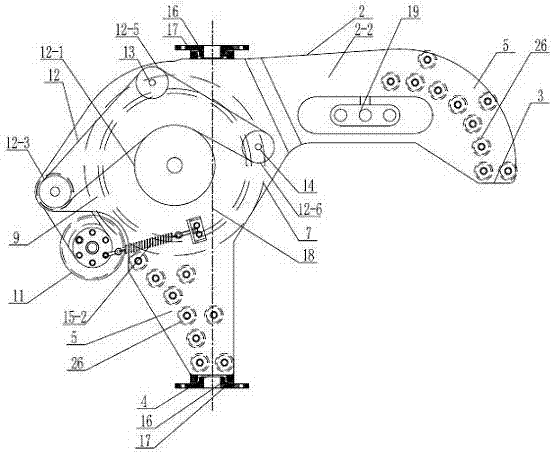

[0053] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0054] The invention comprises a pendulum 2, in which a conveying channel for a neutral cable is set, a driving device for conveying a neutral cable, a reversing device for conveying a neutral cable, a pressure regulating mechanism for a neutral cable and a neutral cable conveying channel are arranged on the pendulum 2. Cable discharge mechanism 19, its structure is respectively as follows:

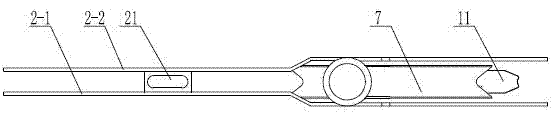

[0055] 1. The transmission channel of the pendulum 2 and the neutral cable——

[0056] See figure 1 , figure 2 , image 3 , the swing frame 2 is formed by connecting the front support plate 2-1 and the rear support plate 2-2 at different intervals, the left distance between the front support plate 2-1 and the rear support plate 2-2 is smaller than the right distance between the two, and the swing frame 2 A hydraulic motor 1 is installed on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com