Vane compressor or vacuum pump

A compressor and vane technology, applied in the field of vane compressors or vacuum pumps, can solve the problems of fast wear of compressors or vacuum pumps, poor sealing performance, low output pressure, etc., and achieve the effects of high pressure, not easy to wear, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

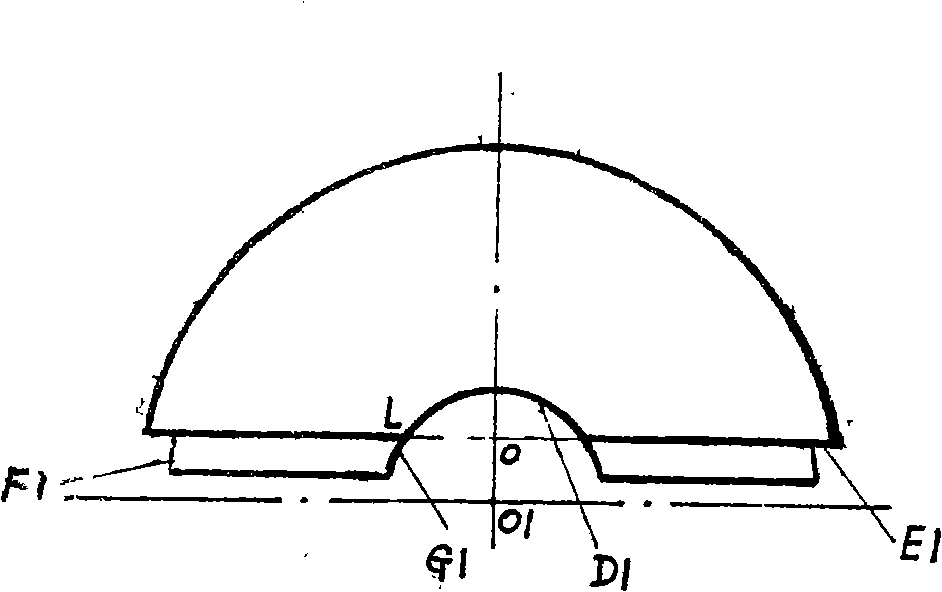

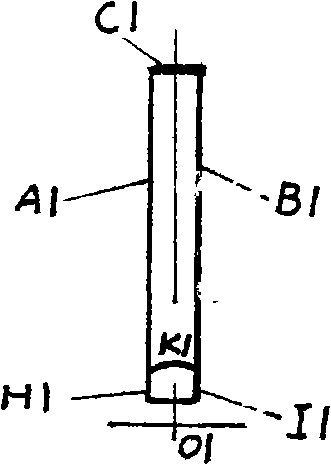

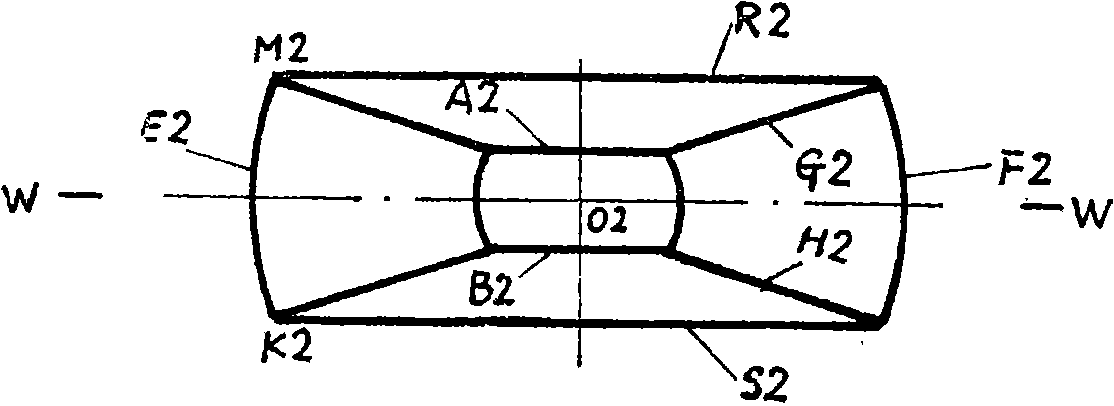

[0035] The structure of the present invention is shown in Figure 5, the rotor 2 is located at the center, the housing 1 is located at the outside, and the blades 3 are located on both sides of the rotor 2, and are placed in the hollow ring (guide groove) at the opposite corner of the housing 1, and are connected with the rotor 2 form an angle, the vane 3 is tangent to the side of the circular table of the rotor 2, the sealing strip 4 is located between the rotor 2 and the vane 3, the plane side of which is attached to the rotor 2, and the cylindrical side is attached to the vane 3, and the gasket The block 5 is located in the hollow circle at the opposite corner of the housing 1, just filling the void formed by the blade 3, the rotor 2 and the sealing strip 4.

[0036] Figure 1a and Figure 1b Shown are the shapes of the blade 3 and the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com