Submarine cable including lead stuffing

A technology for submarine cables and cable tubes, which is applied in the direction of submarine cables, bendable cables, and extendable conductor cables, etc. It can solve problems such as damage, cable tube breakage, and submarine cables taking a lot of time and money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

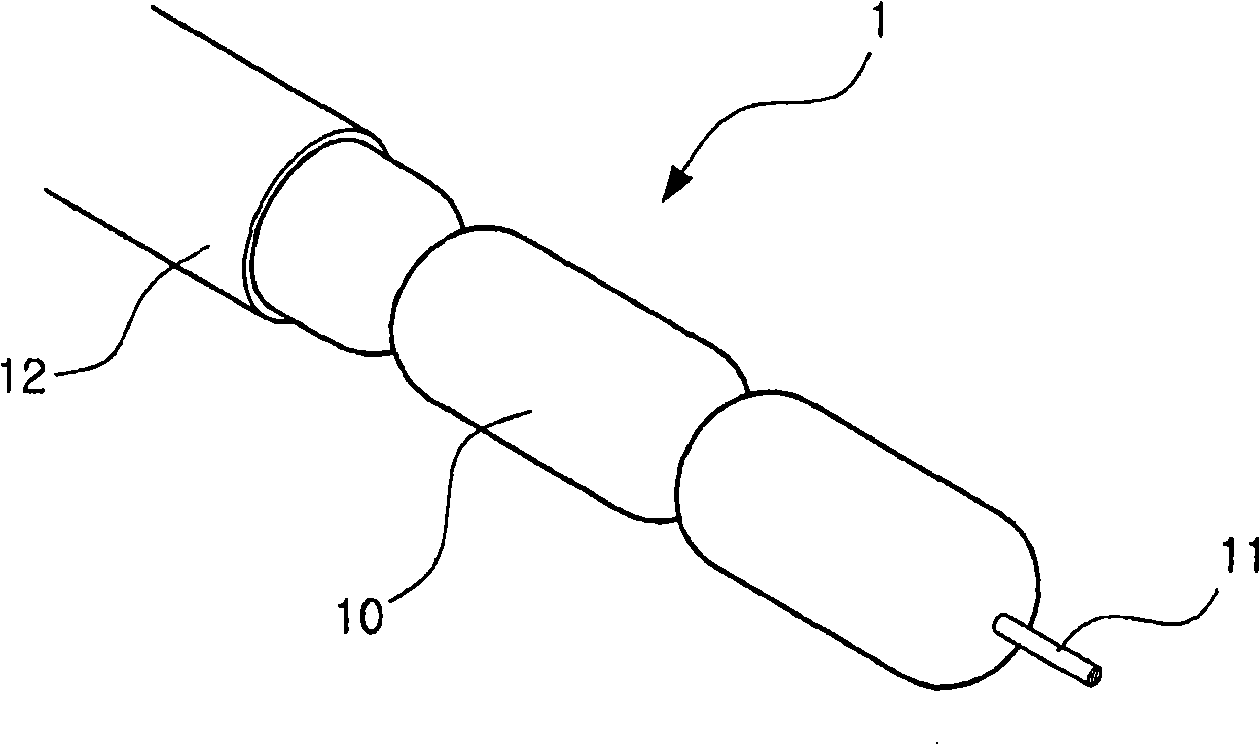

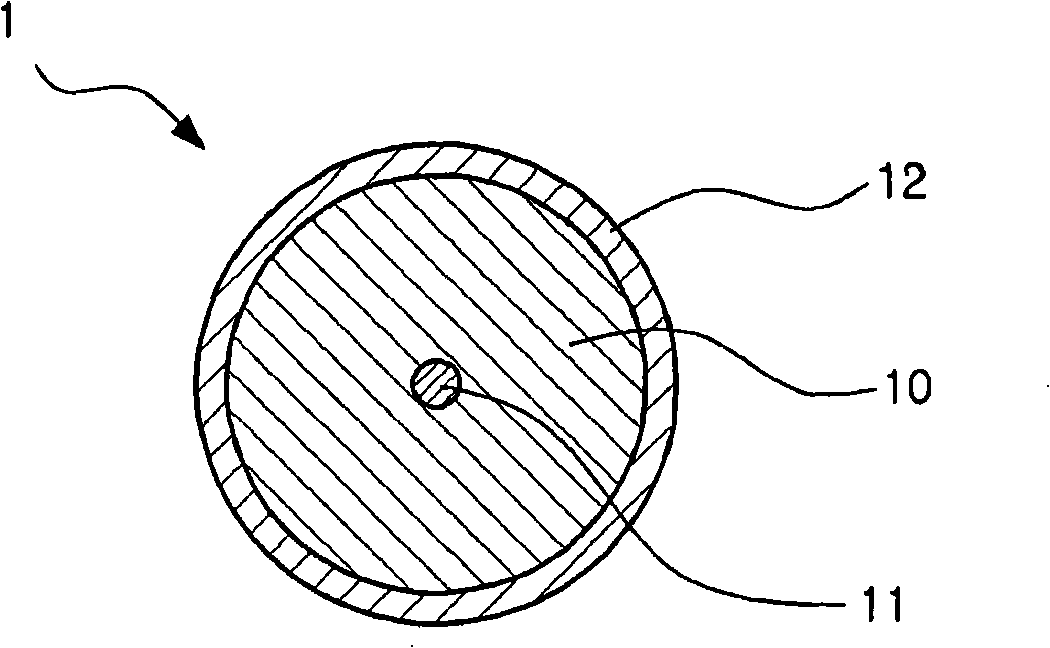

[0014] refer to figure 1 with figure 2 , the lead filler 1 includes a flexible rope 11 . The flexible rope 11 is made of polystyrene or polyethylene. The lead filler 1 also includes an outer sheath 12 . The outer sheath 12 serves to prevent direct contact between the power cable and / or the communication cable and the lead mass 10 which is one of the components constituting the lead filler 1 . The outer sheath 12 is preferably made of non-woven fabric or polypropylene.

[0015] Such as figure 1 As shown, the lead weights 10 are interconnected along ropes 11 in a sausage connection to give the lead filler 1 flexibility, which allows the lead filler 1 to be properly bent and elastic, which allows the lead filler 1 to expand and contract properly.

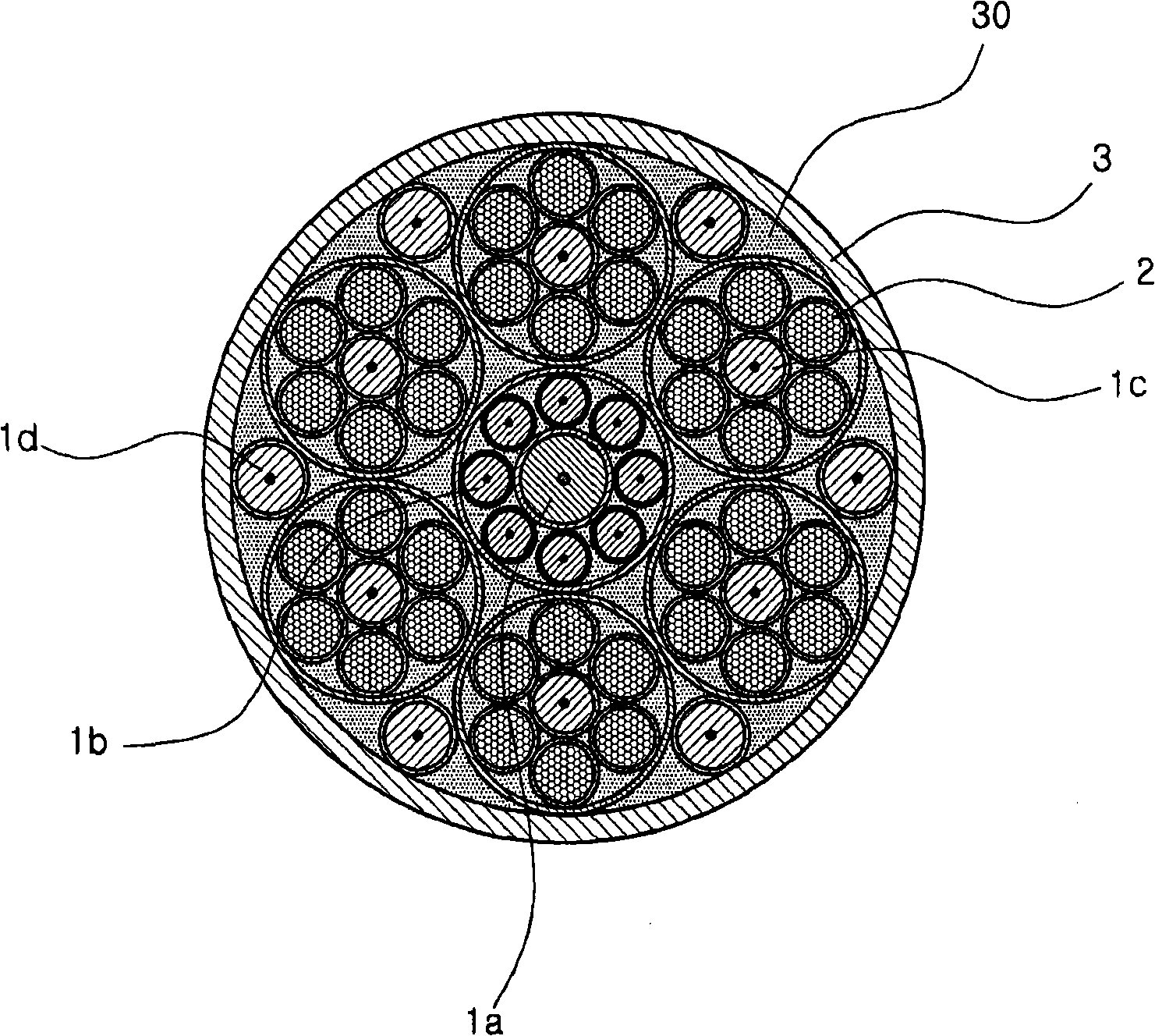

[0016] At the same time, if image 3 As shown, the lead filler 1 is arranged in the cable duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com