Electromagnetic induction low-voltage non-polar lamp

An electromagnetic induction, electrodeless lamp technology, applied in discharge lamps, circuits, electrical components, etc., can solve the problems of large space, unfavorable product miniaturization and compactness, limited use range, etc., to achieve compact structure, expand use range, Improve the overall aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

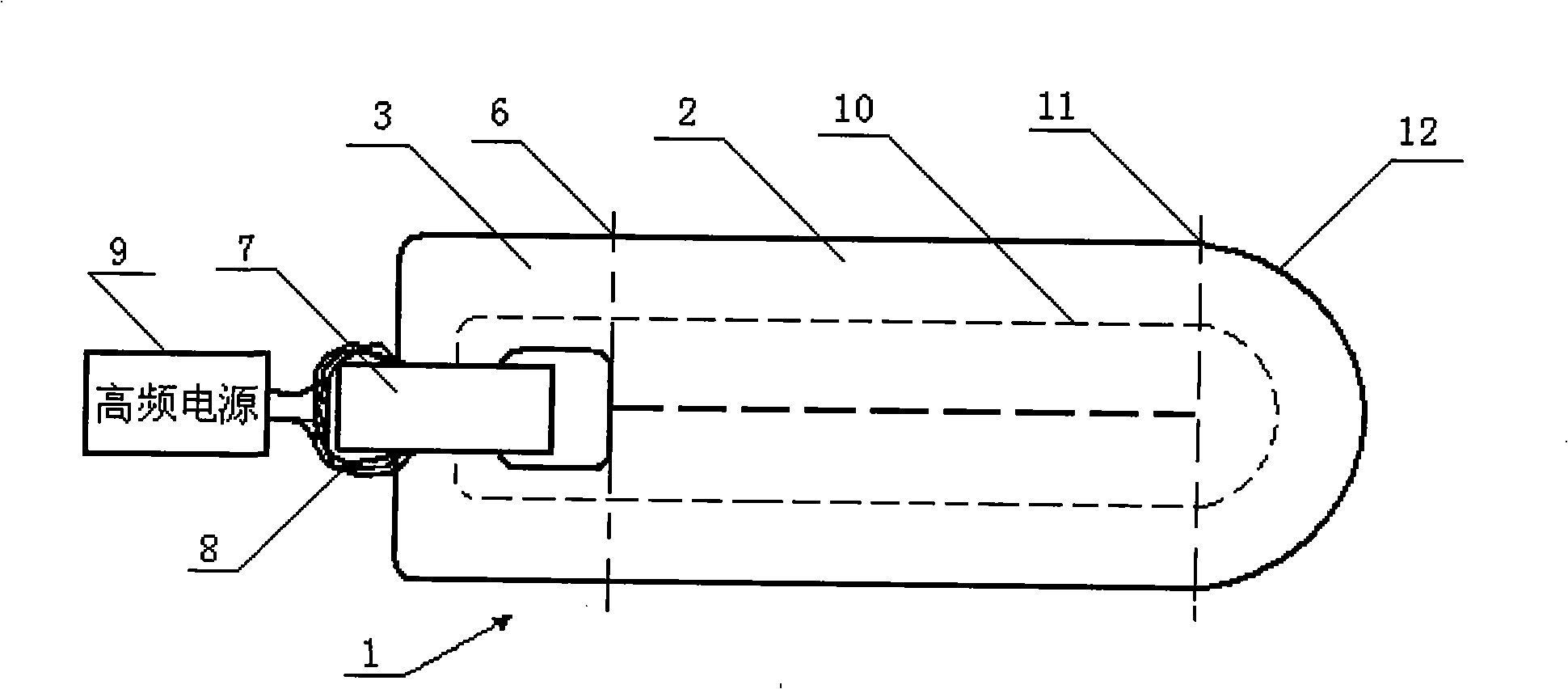

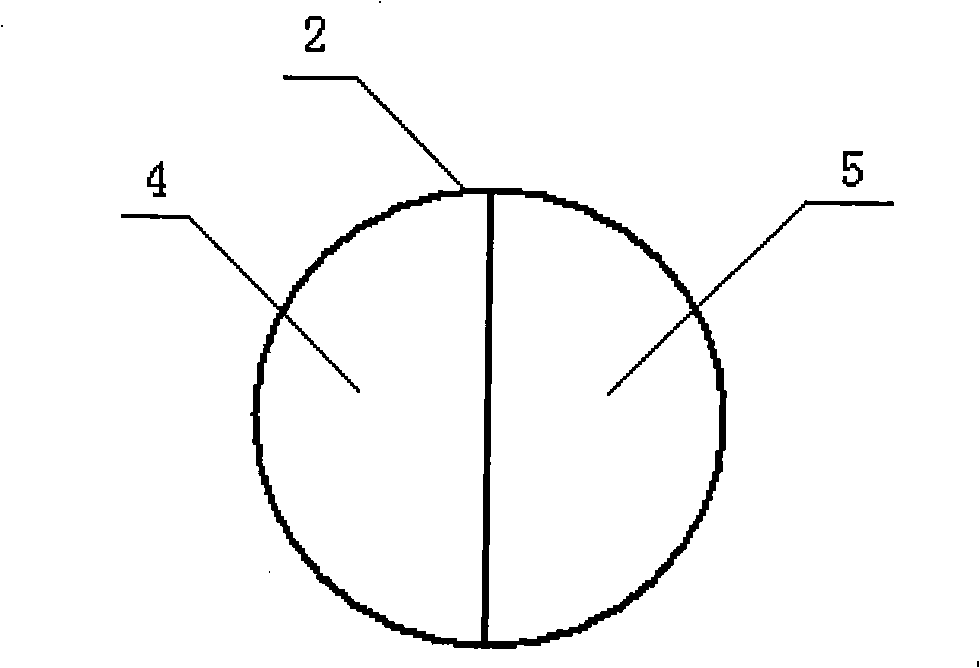

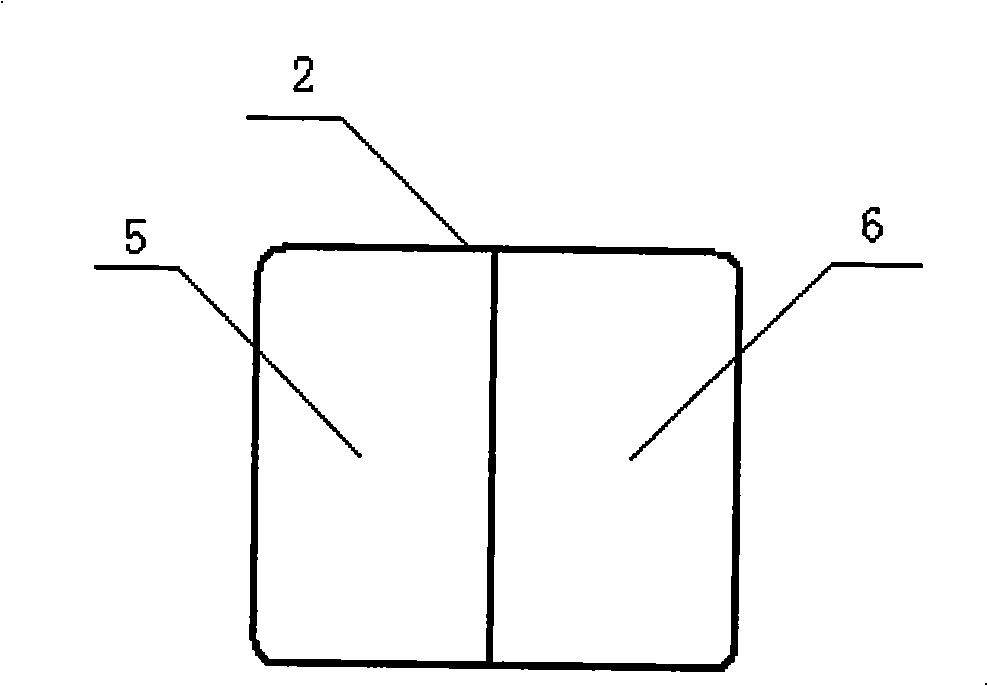

[0026] figure 1 The first embodiment of an electromagnetic induction low-voltage electrodeless lamp of the present invention is shown. It can be seen from the figure that the electrodeless discharge chamber 1 includes a lamp housing forming a closed circuit 10, the lamp housing contains mercury and an inert gas, and the inner surface of the lamp housing is provided with a fluorescent coating (not shown), and forms a closed circuit 10. There is a double-hole glass tube 2 and a U-shaped single-hole glass tube 3 in the lamp housing of the circuit. The double-hole glass tube 2 is connected to the U-shaped single-hole glass tube at one end 6. The glass tube 3 is sealed and the two glass holes at the end are respectively communicated with the glass holes at both ends of the U-shaped single-hole glass tube. The shell 12 is sealed and connects the two glass holes at this end; a transformer core 7 provided with an input coil 8 is arranged around the single-hole glass tube 3, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com