Escapement for electric power line without bolt

A technology without bolts and spacers, applied in the installation of electrical components, cables, devices for maintaining the spacing between parallel conductors, etc., can solve the problems of complex spring bearing parts, no specific representation, inconvenient heights, etc., to relieve stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below, refer to Figure 1 to Figure 8 An example of the present invention will be described.

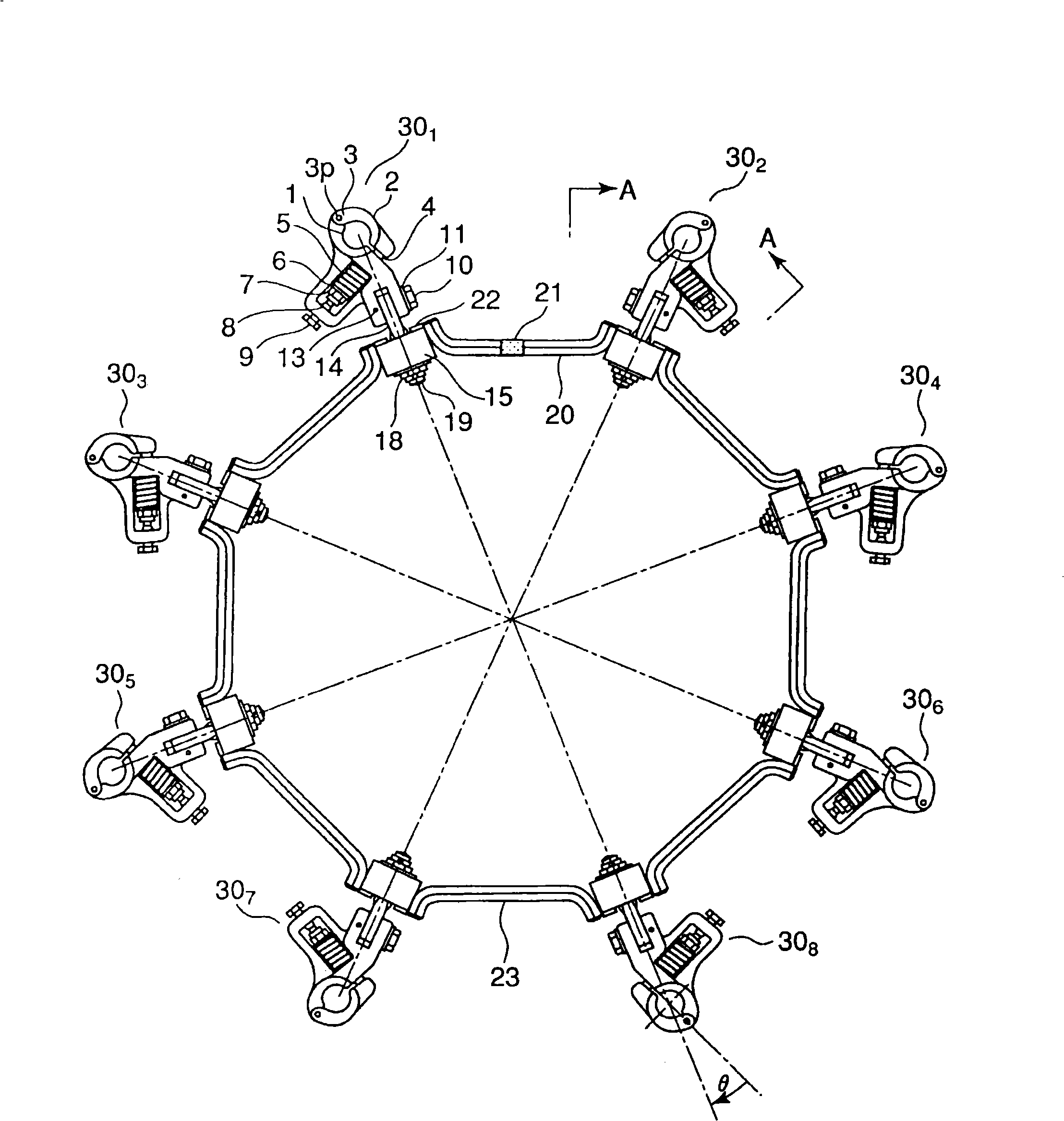

[0042] figure 1 It is a front view of a boltless spacer for 8 conductors when the spacer of the present invention is applied to a UHV8 conductor transmission line.

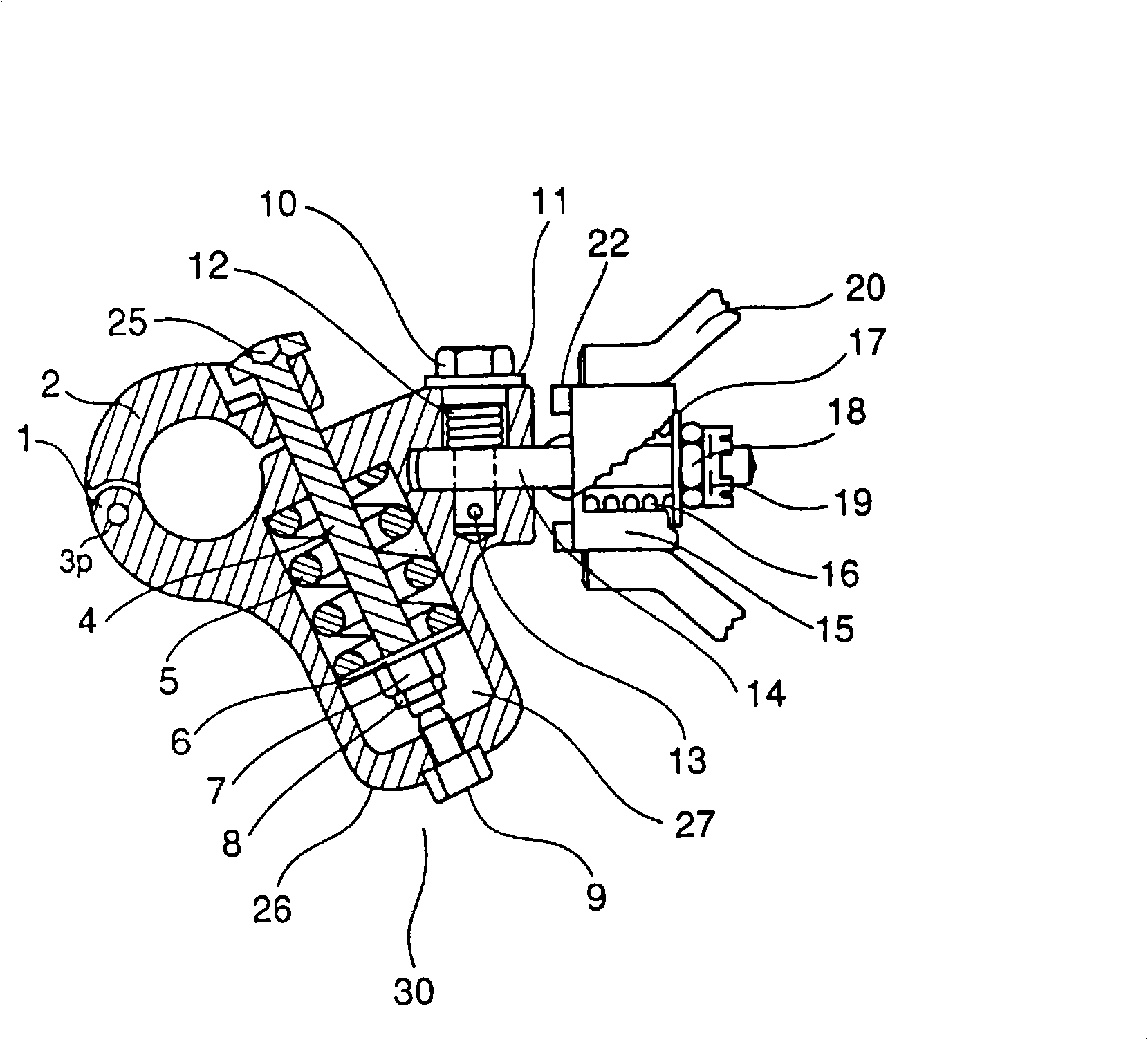

[0043] figure 2 It is no bolt electric wire grip part 30 1 enlarged sectional view of the .

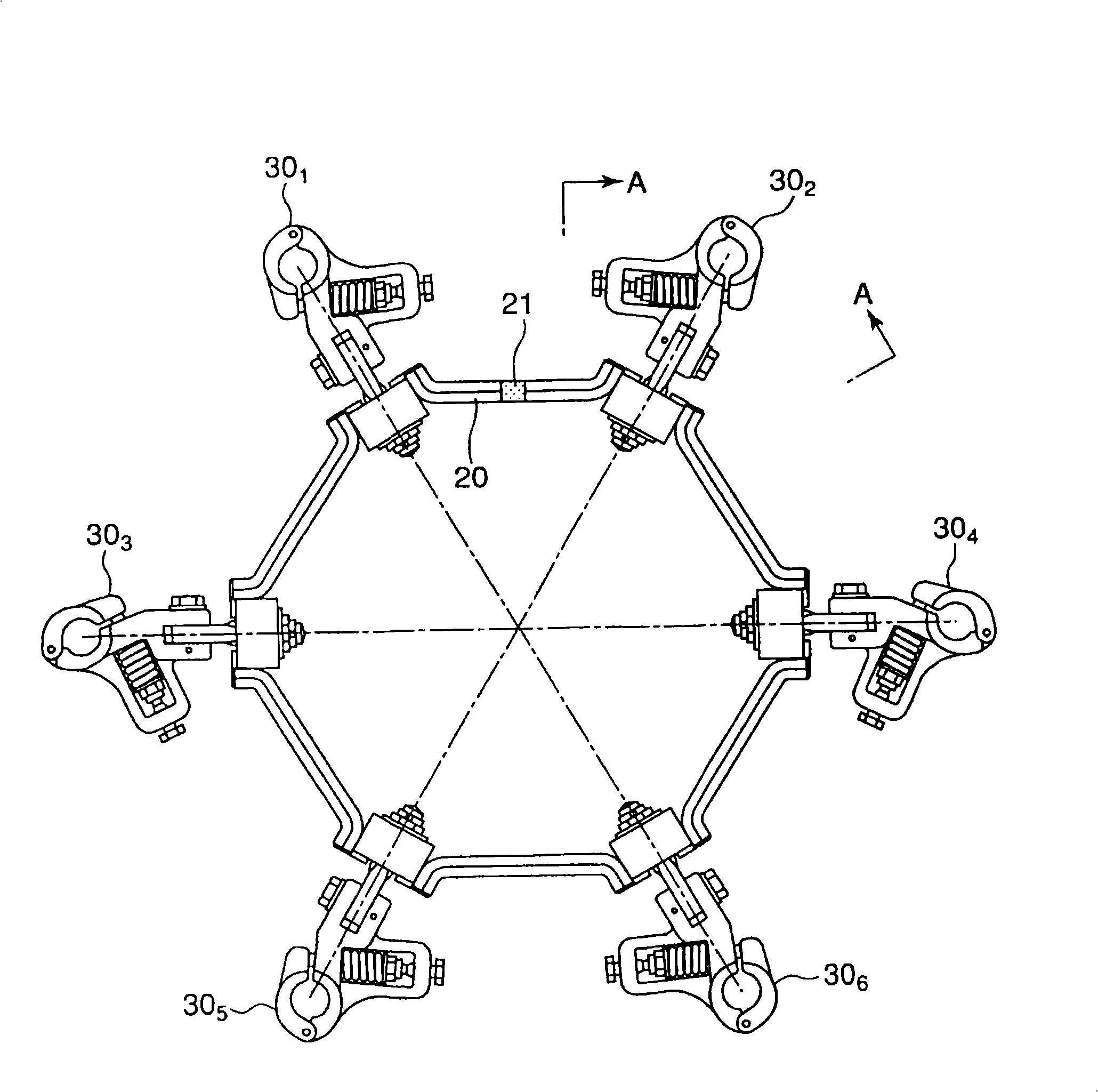

[0044] image 3 It is a front view of a 6-conductor boltless spacer for UHV power lines or UHV power lines.

[0045] In addition, in the following description, in the 8-conductor and 6-conductor boltless spacers, except that the mounting intervals of the former to the frame are 45° and the latter are mounted at 60° intervals, the boltless wire holding part and the boltless spacer to the frame The basic structure of connecting frames is the same, so the boltless spacer for 8 conductors will be explained.

[0046] First, the structure of the spacer of the present invention will be described by taking an 8-conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com