Automatic charger of traction accumulator

A traction battery and automatic charging technology, which is applied to battery circuit devices, electric vehicles, collectors, etc., can solve the problems that the performance of the charger does not meet the battery charging, does not meet the battery charging requirements, and reduces the service life of the battery, so as to reduce resources. Utilization, the effect of less battery heat generation and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following further describes the embodiments of the present invention according to the drawings:

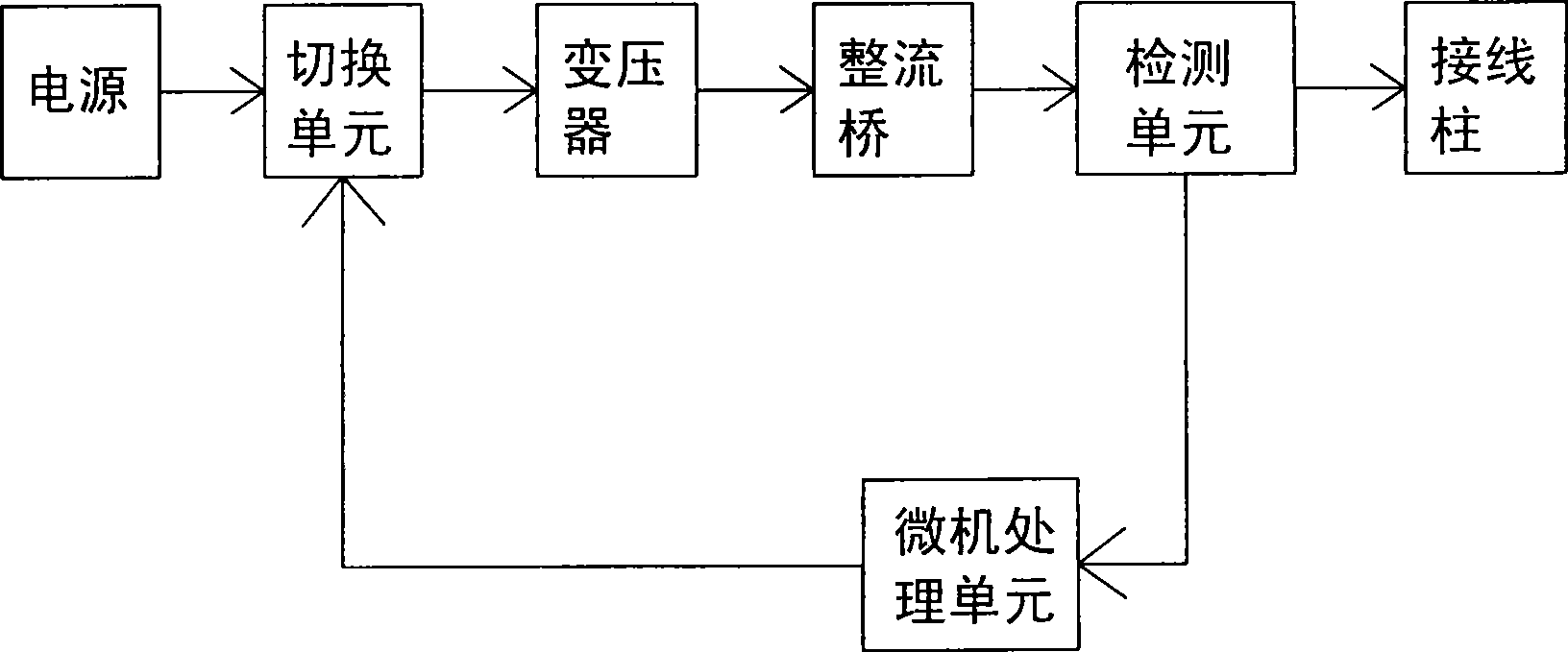

[0021] Such as figure 1 As shown, the primary side of the transformer is connected to the main power line, the secondary side is connected to the input end of the rectifier bridge, and the output end of the rectifier bridge is connected to the terminal. The detection unit is arranged on the output end of the rectifier bridge and the wire of the terminal, the output end of the detection unit is connected to the input end of the microcomputer processing unit, and the output end of the microcomputer processing unit is connected to the input end of the switching unit. The switching unit is arranged on the main line of the power supply and the conductor on the primary side of the transformer.

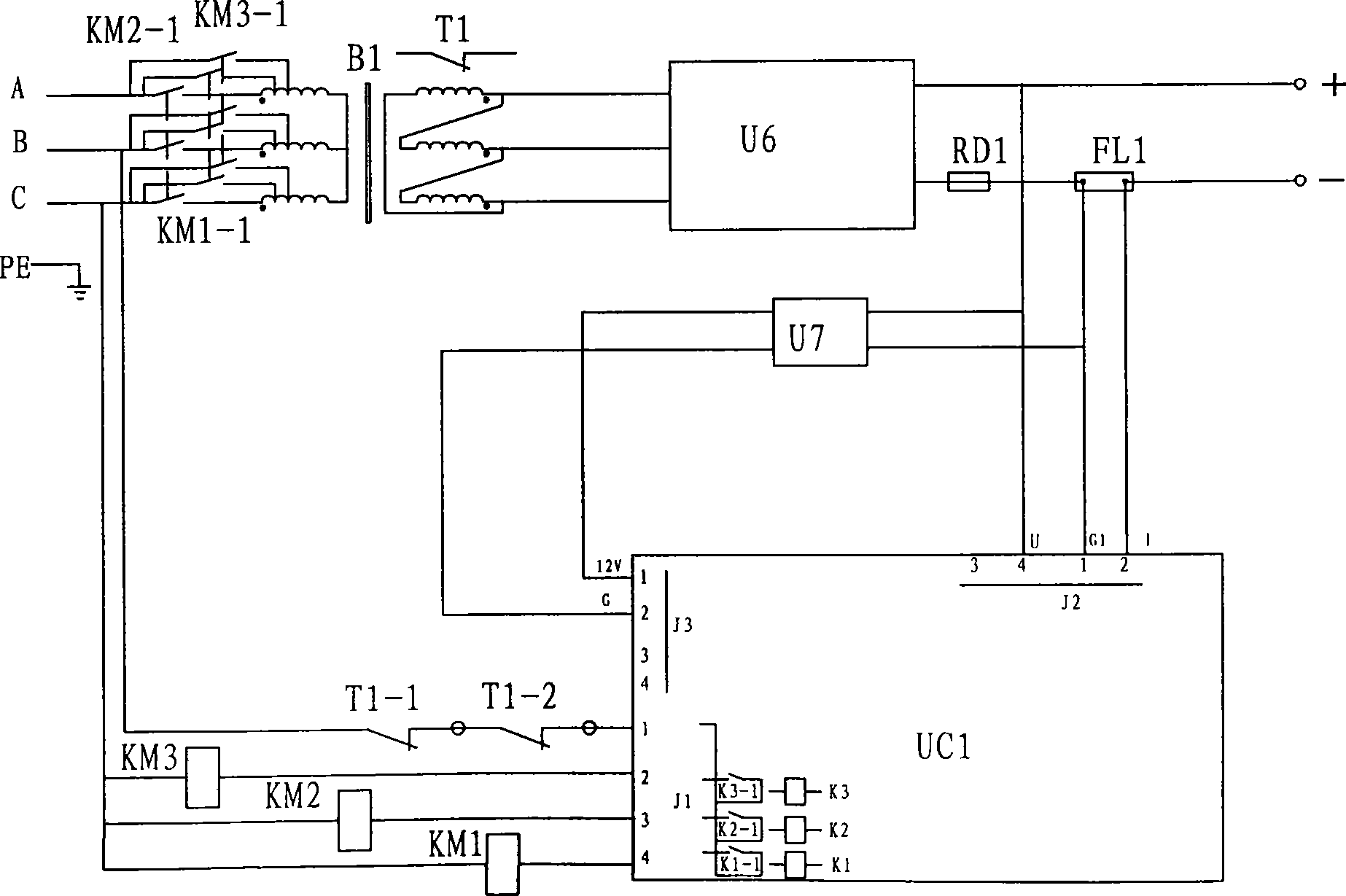

[0022] A fuse protector is set on the wire between the output end of the rectifier bridge and the terminal ( figure 2 Shown).

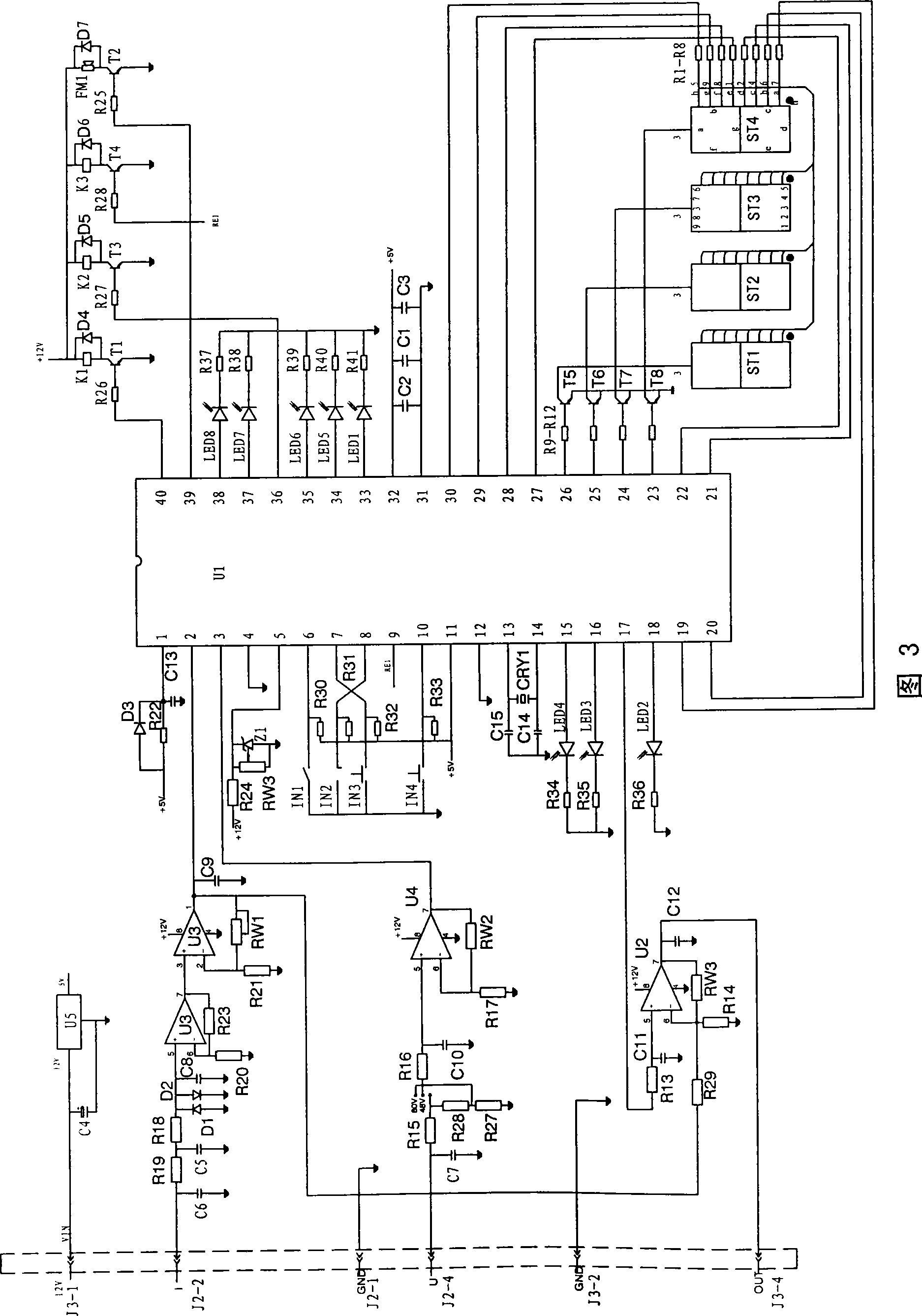

[0023] The microcomputer processing unit, the detection uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com