Side flow lamella using standard box body

A technology of inclined plate precipitation and lateral flow, which is used in settling tanks, water/sewage treatment, water/sludge/sewage treatment, etc. different problems, to achieve the effect of effectively using the site, reducing the site occupancy, simplifying the production process and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

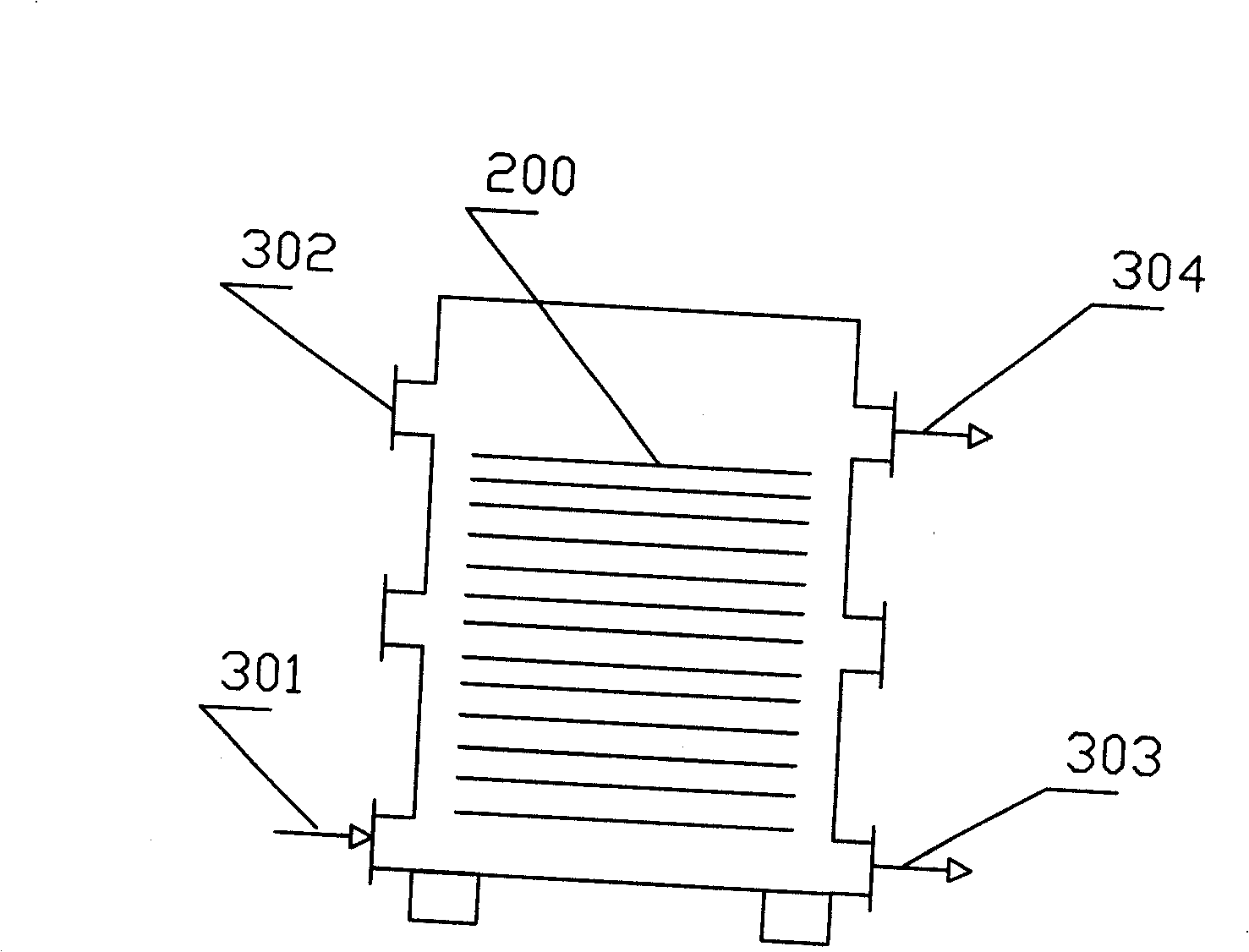

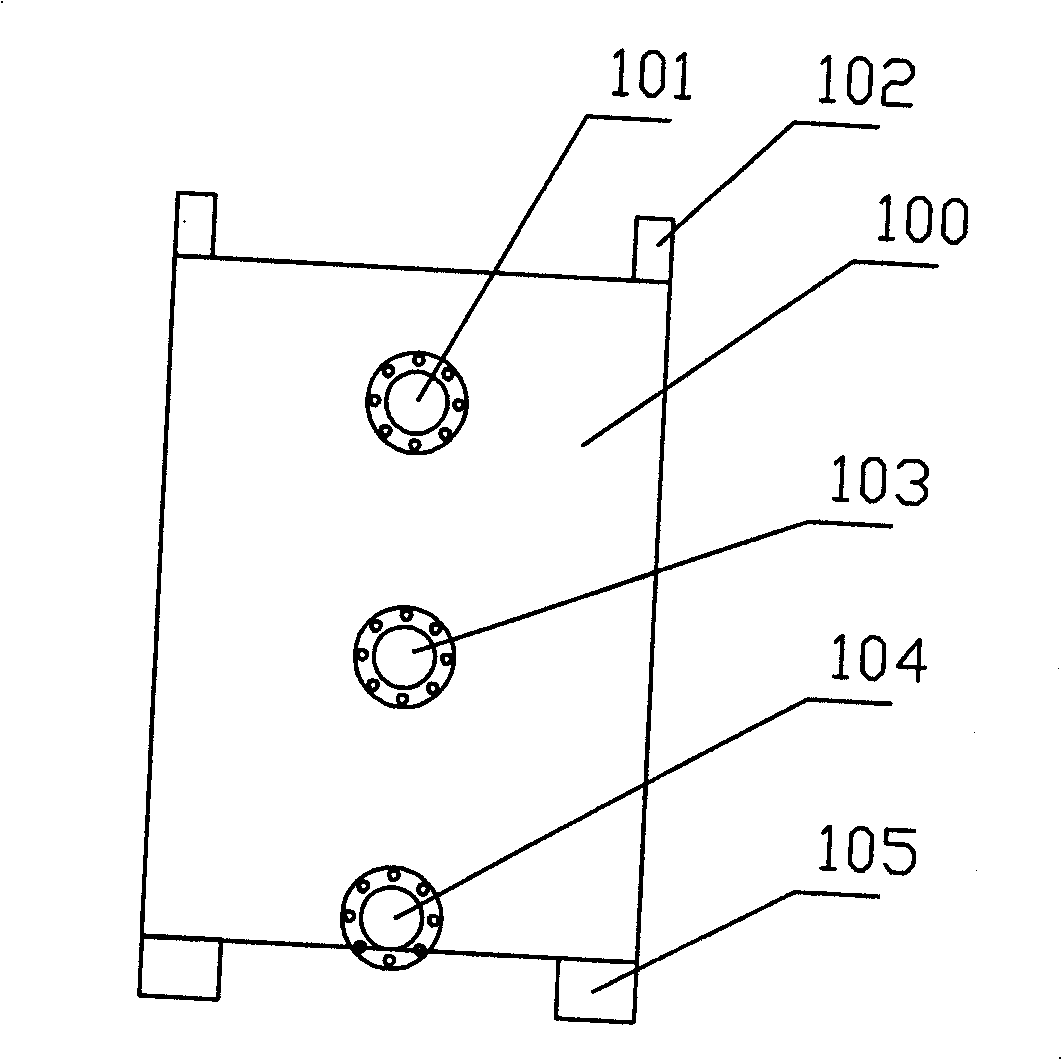

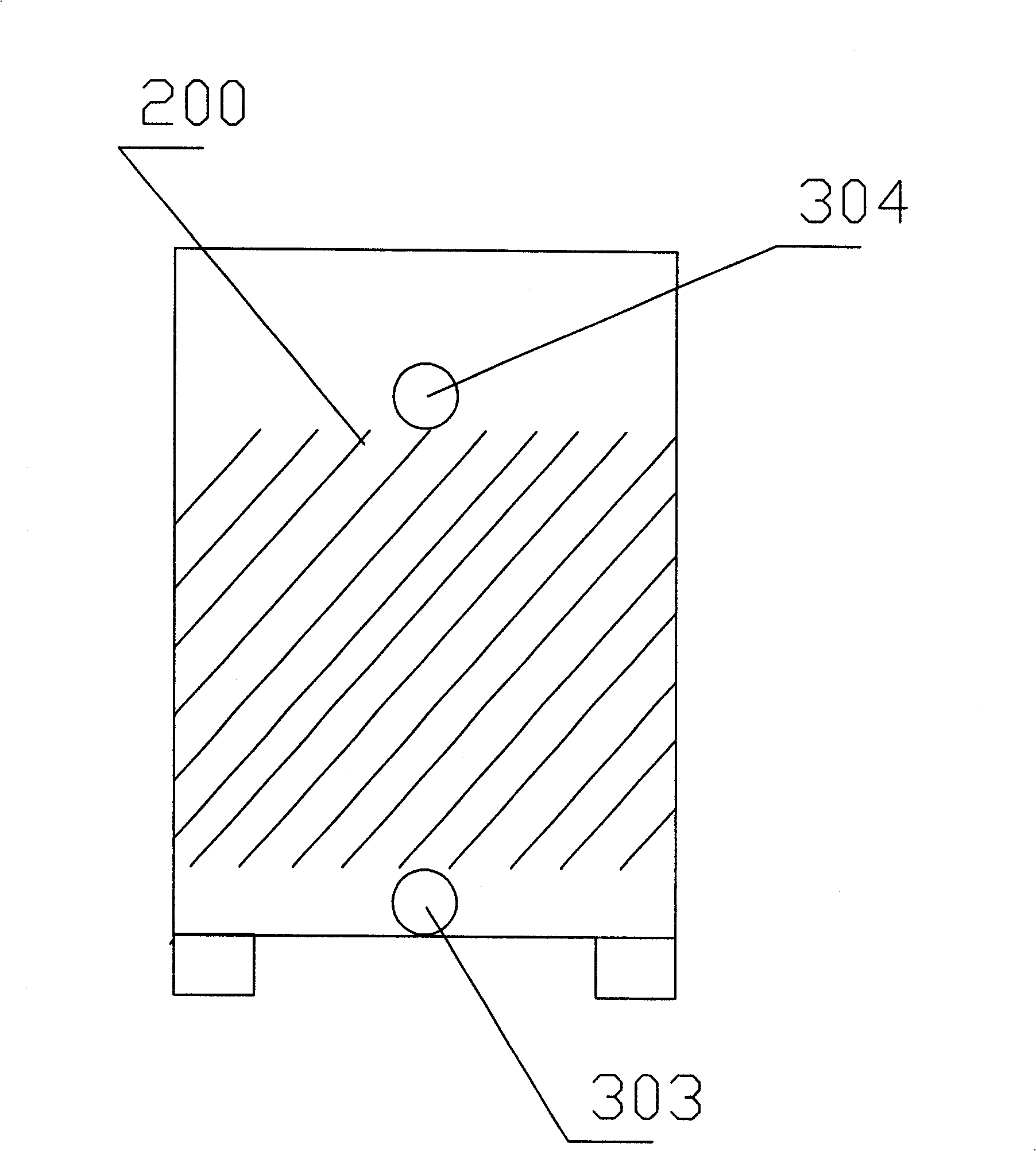

[0010] see Figure 1-Figure 3 , the present invention provides a lateral flow sloping plate sedimentation tank using a standard box body, including a standardized box body 100, the box body is rectangular, and its two ends are respectively provided with three identical upper, middle, lower, and flanged tanks. Connecting short pipes 101, 103, 104, the box is provided with a number of sloping plates 200 distributed at equal intervals, and the inclination direction of the sloping plates is perpendicular to the water flow direction (the box body is from left to right or from right to left) Direction) is inclined from bottom to top, not inclined in the direction of water flow (from the front end of the box to the rear end), the lower connecting short pipe 301 at the front end of the box is the water inlet, and the upper connecting short pipe 304 at the rear end of the box is the water outlet .

[0011] There is a distance between the front and rear ends of the sloping plate and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com