Method for processing cone gage with multiple steepness

A technology of taper gauge and processing method, which is applied in the direction of angle/taper measurement, etc., can solve the problems of easy scrapping and difficult processing of multi-slope taper gauges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

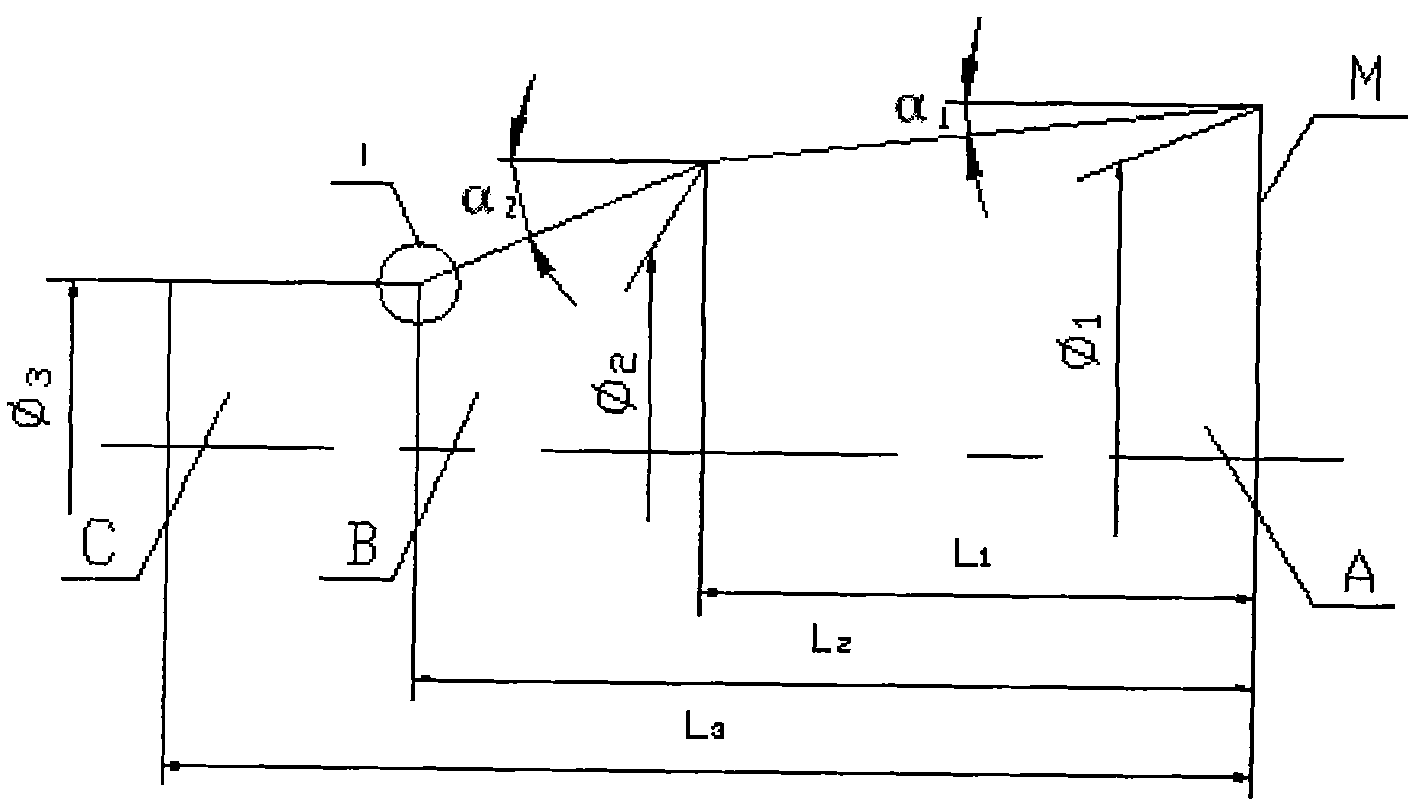

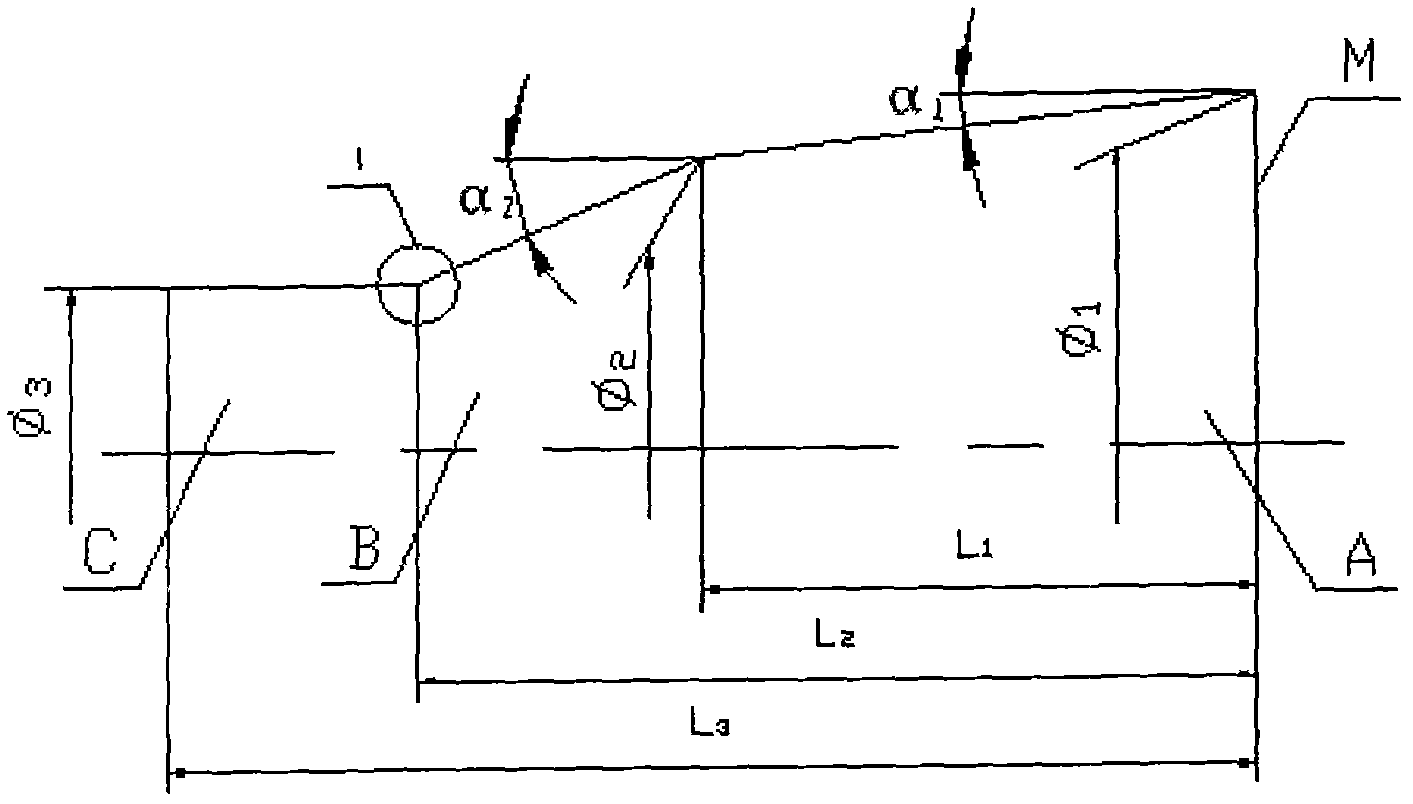

[0037] See figure 1 with figure 2 , Processing method of multi-slope taper gauge:

[0038] 1. Blanking: use GCr15 or GrMn as the material and forging the blank, the diameter is 8-10mm, the length is 20mm.

[0039] 2. Rough turning gauge: The gauge leaves 5mm margin for quenching and tempering.

[0040] 3. Tempering: HRC <10.

[0041] 4. Precision car gauge:

[0042] (1) The straight outer circle C, the diameter of the grinding allowance is 0.80mm, and the length is (L 3 -L 2 ) Car Cheng.

[0043] (2) Machining the center hole of the M end, the 60° cone length is 0.8~1.5mm.

[0044] (3) Car cone A, according to diameter Φ 1 Turn into a straight outer circle with a grinding allowance of 1mm, and the length is L 2 Car into, angle α 1 Processing in the later process.

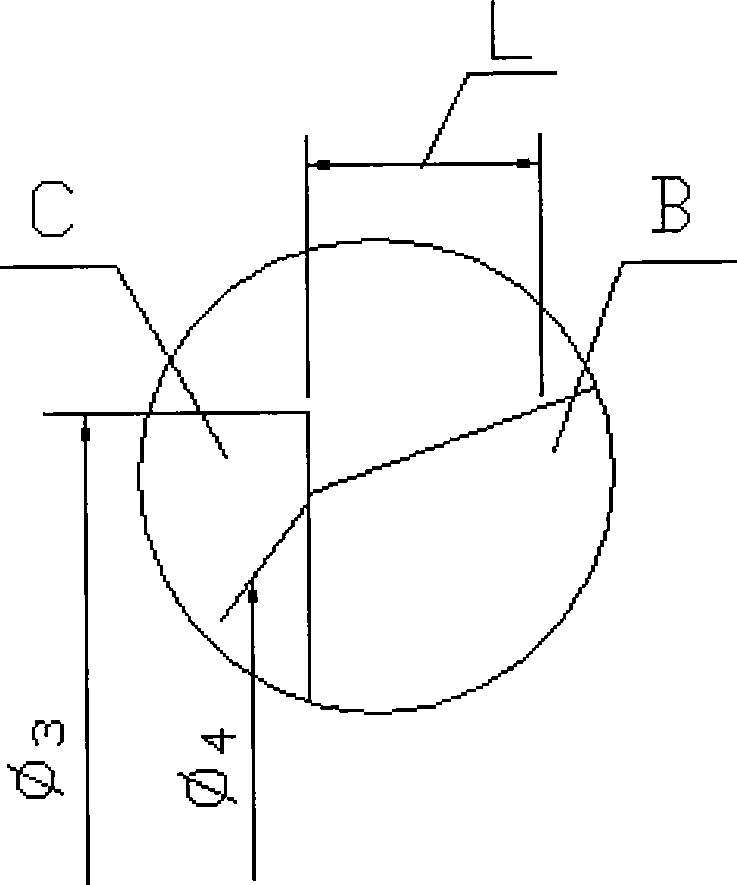

[0045] (4) Car inclined shoulder B, the actual processing angle is greater than α 2 The diameter of the car is the diameter of the straight outer circle C Φ 3 car.

[0046] (5) Car angle α 1 , Starting from the actual big end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com