Aluminum melt furnace refining device

A technology for in-furnace refining and aluminum melt, applied in the field of in-furnace refiners, can solve the problems of low degassing and slag removal efficiency, short floating distance and time, etc. The effect of recontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

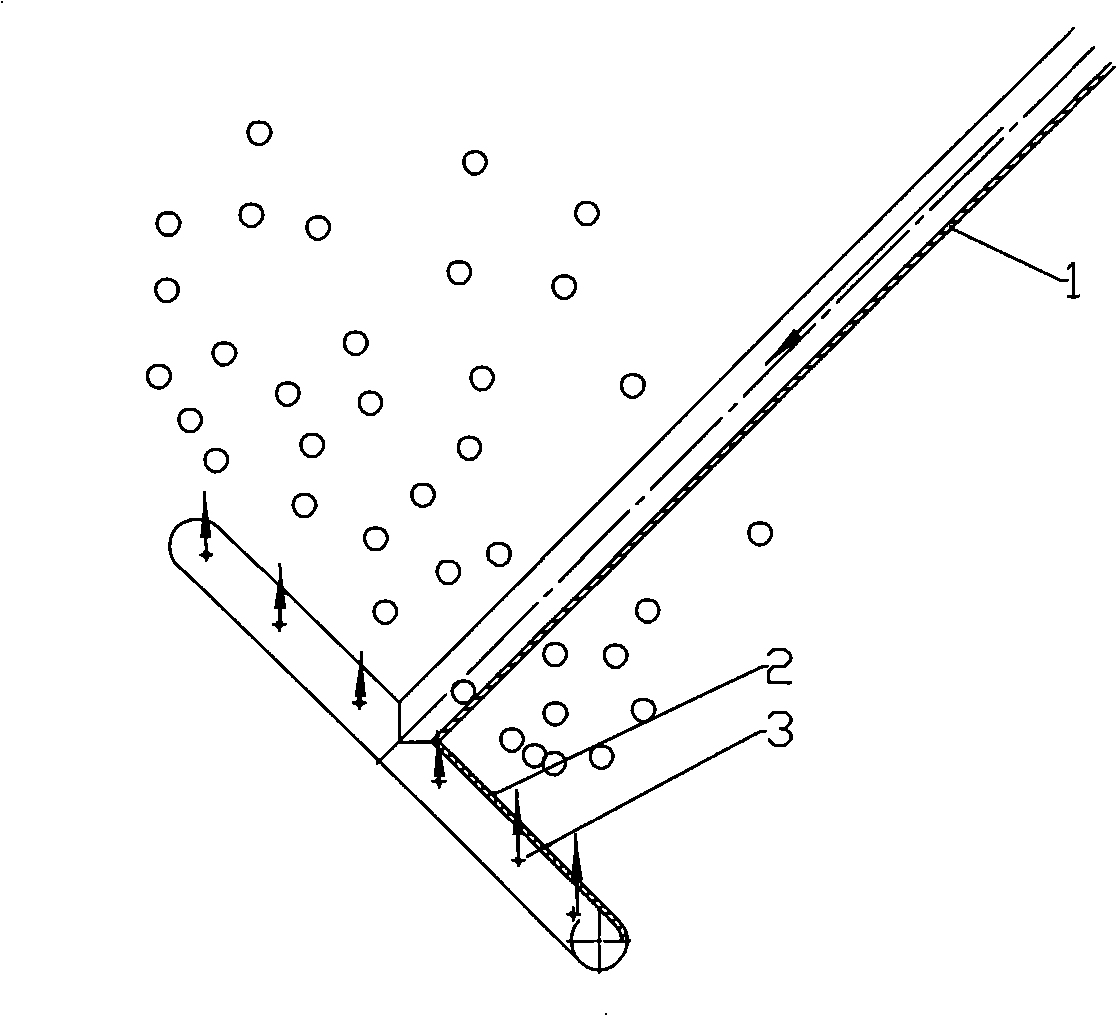

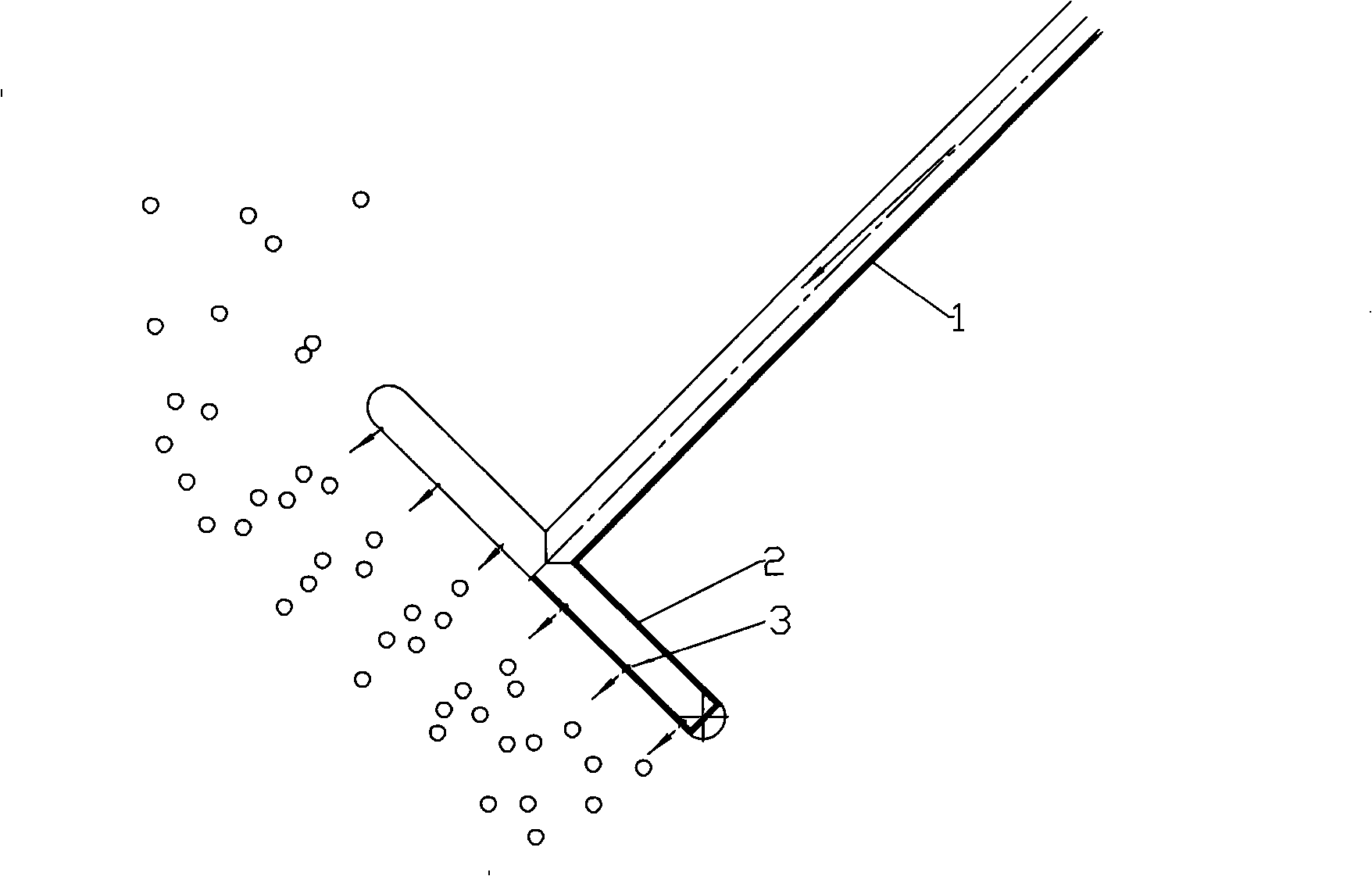

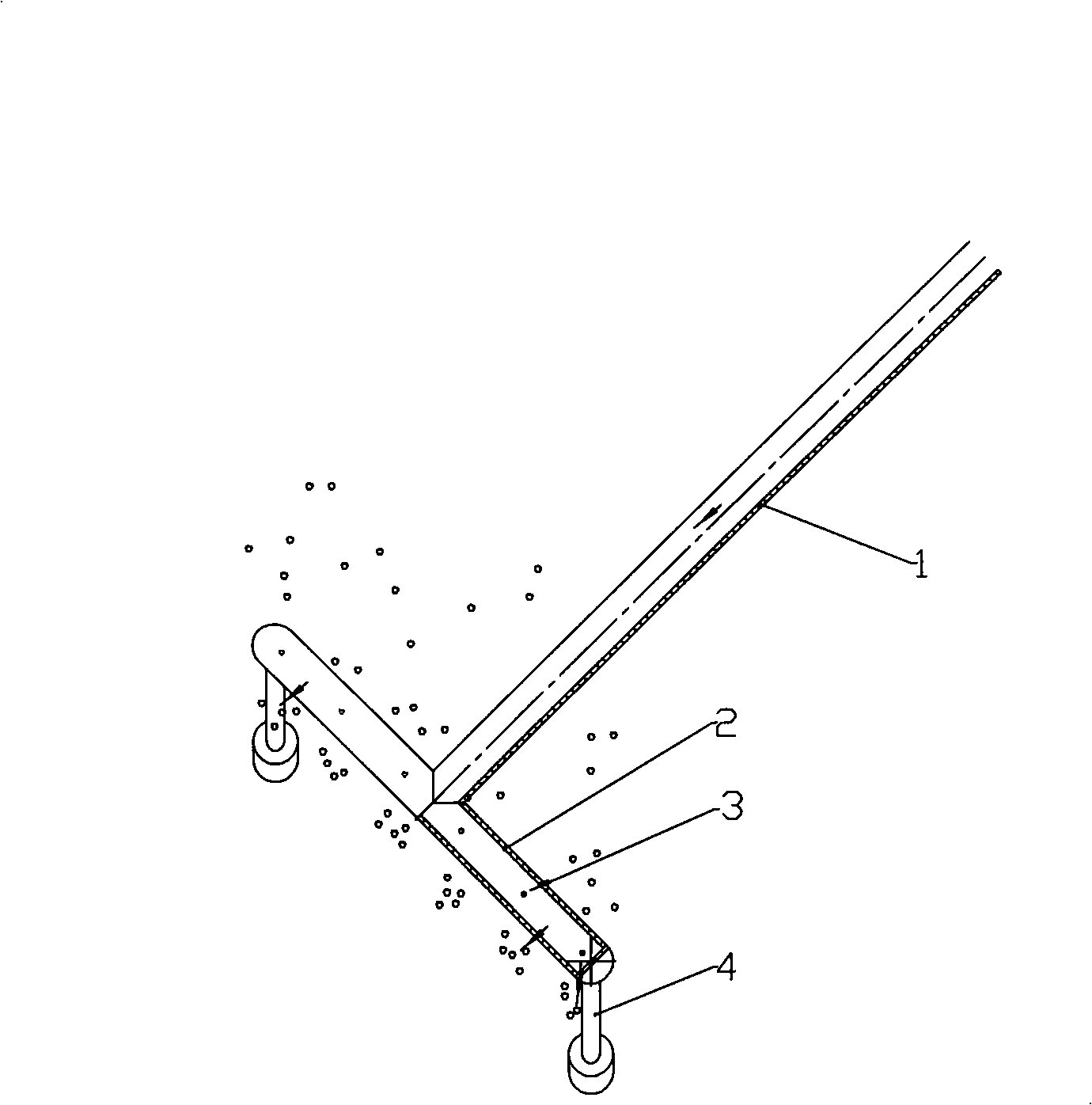

[0011] like figure 2 The shown refiner in the aluminum melting furnace includes a horizontally placed refiner head 2 connected to the inlet pipe 1 of the refiner. The refiner head 2 is a round tube, and the outlet on the refiner head is The air hole 3 is located on the tube wall at the level of the axis line of the refiner head. In this way, after the refined gas enters the refiner head 2 from the inlet pipe 1 and diverts to both ends, it is ejected horizontally from the air outlet 3 of the refiner head 2, and the formed bubbles will float forward for a certain distance along the direction of the air outlet, and at the same time Under the action of buoyancy, the upward overflow prolongs the residence time of the bubbles in the melt and the floating route, so that more hydrogen can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com