Machine for winding core of lithium ion battery

A lithium-ion battery, winding machine technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems affecting the quality and service life of lithium batteries, positive and negative cross-infection of batteries, etc., to achieve simple structure, prevent cross Infection, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

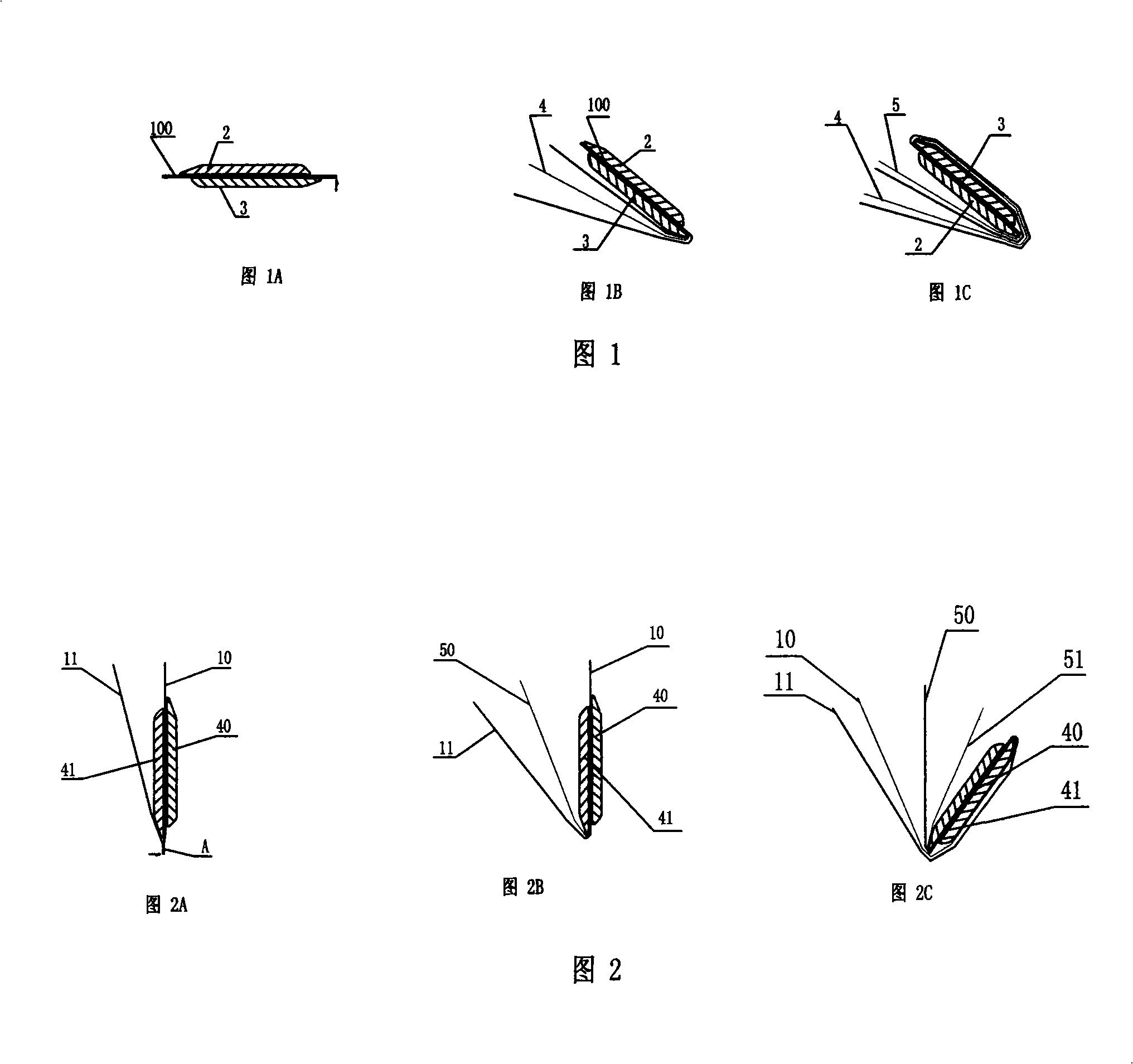

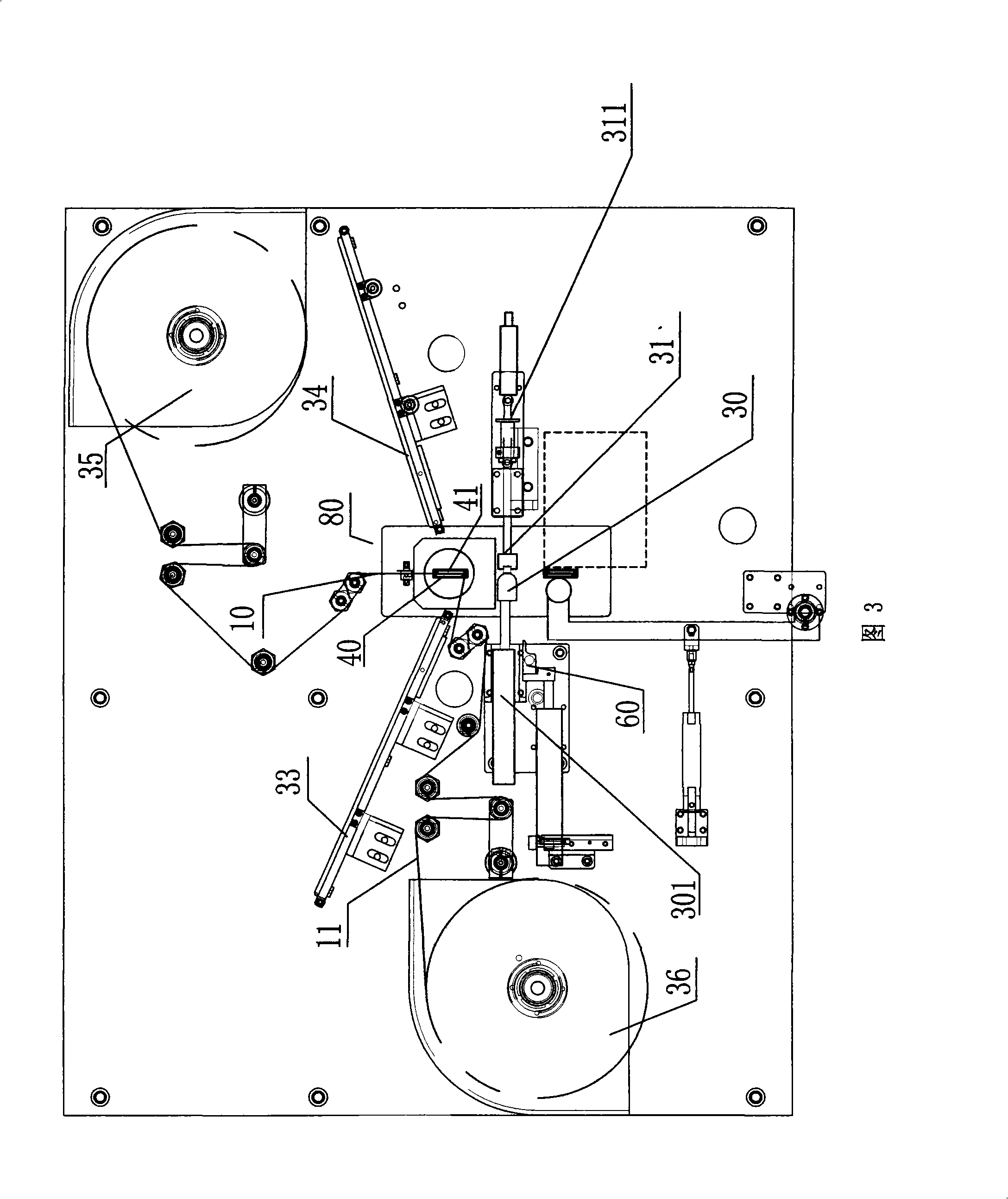

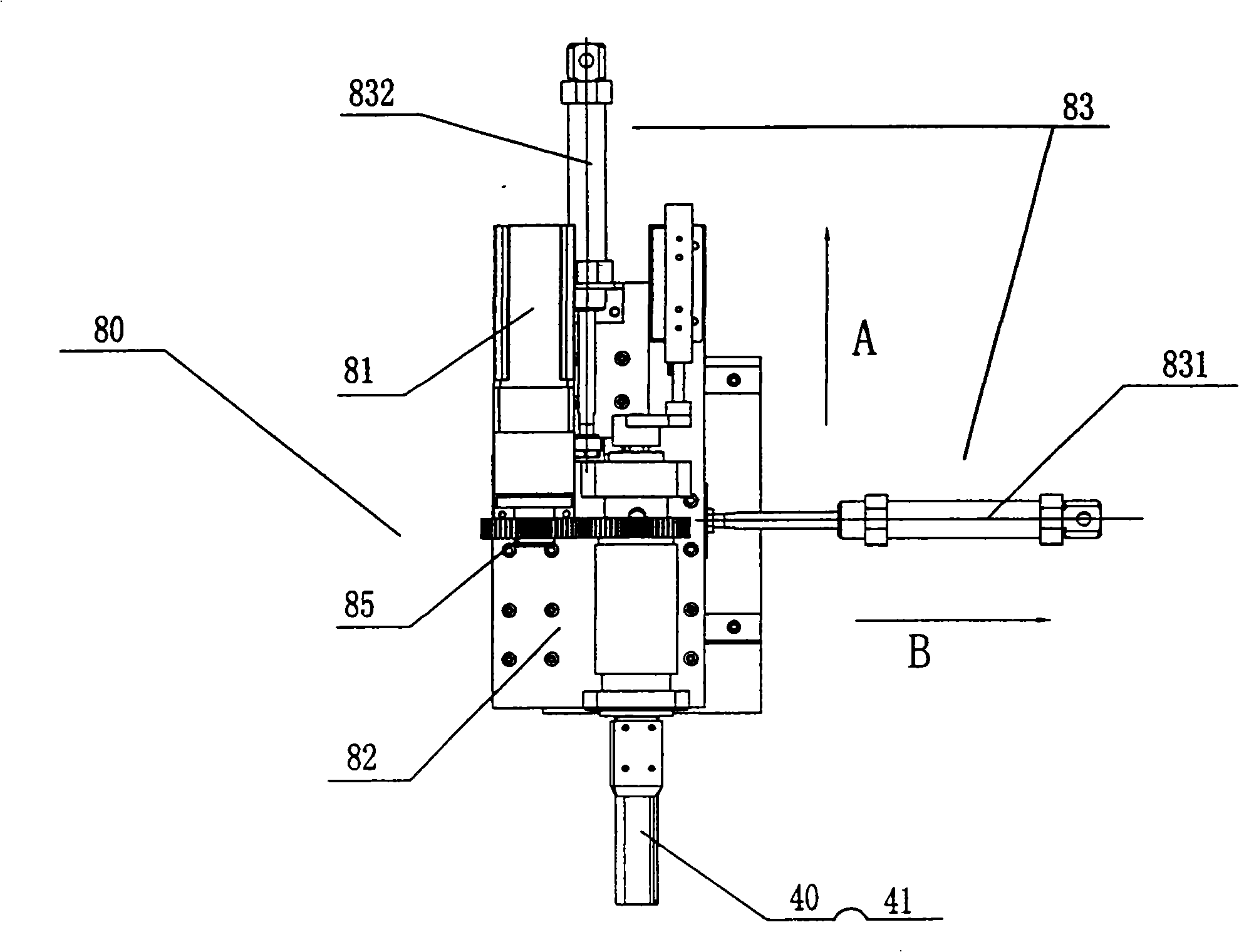

[0021] Lithium-ion battery core winding machine of the present invention, as shown in Figure 3, comprises bipolar sheet feeding mechanism 33,34, two diaphragm feeding mechanisms 35,36, winding transposition mechanism center 80 and diaphragm cutter 60, and The two pressure blocks 30, 31 used to clamp the two diaphragms before the needle and after winding; the diaphragm cutter 60 and the two pressure blocks 30, 31 are driven by their respective drive mechanisms; the winding transposition mechanism center 80 includes Winding motor 81, two volume needles 40,41 and winding transposition mechanism body 82 and transposition drive mechanism 83 (in conjunction with reference Figure 4 ); the first diaphragm feeding mechanism 35 in the two diaphragm feeding mechanisms is located at the upper end of the winding machine, and it puts down the second diaphragm 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com