Motor bearing structure

A technology of bearings and motors, which is applied in the field of motor bearing structures of cooling fans, can solve problems such as damage and increased noise, and achieve good buffering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

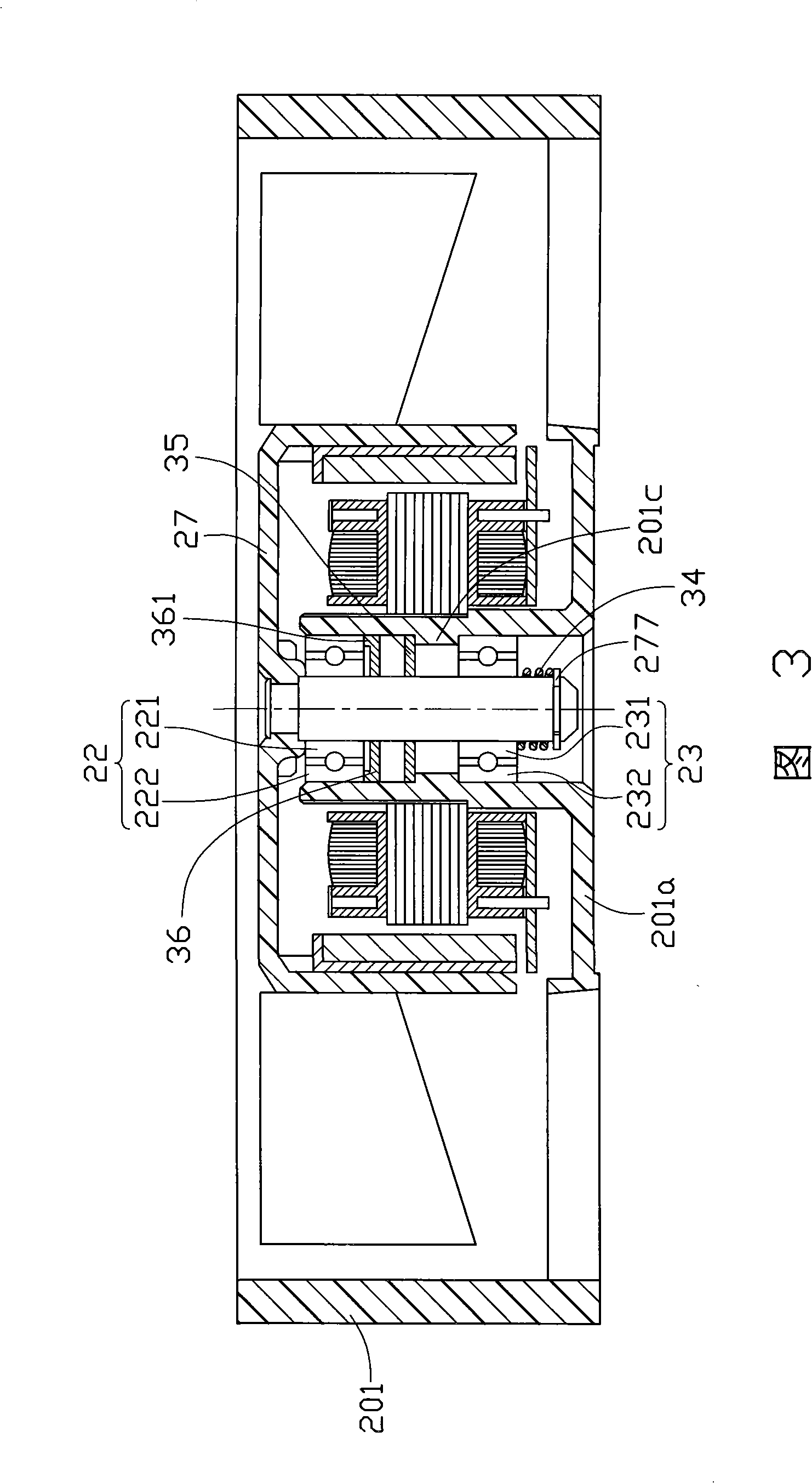

[0013] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

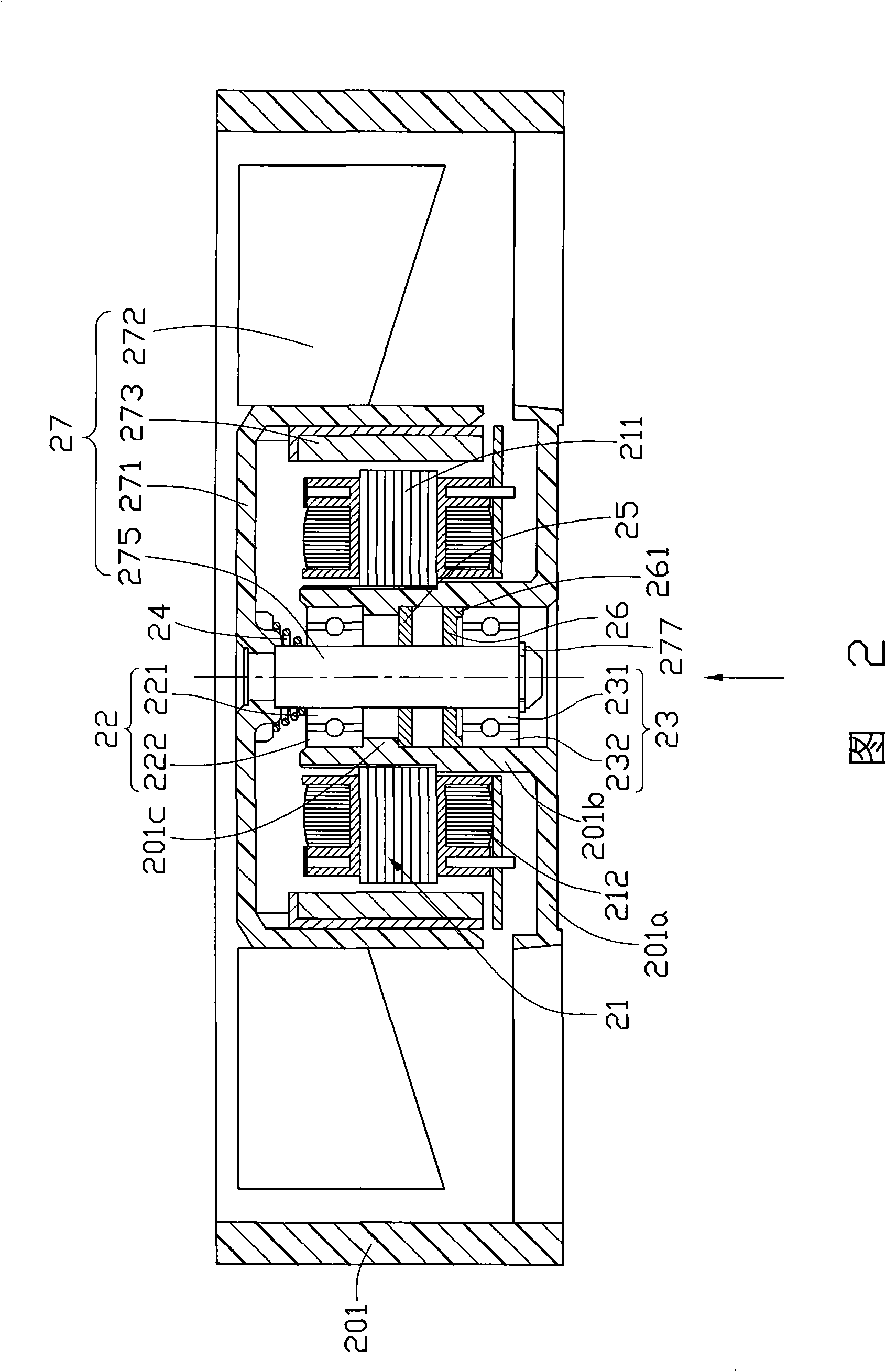

[0014] Figure 2 is a schematic cross-sectional view of the first embodiment of the motor bearing structure of the present invention, the motor bearing structure is arranged in an outer frame 201 of a heat dissipation fan, the bottom center of the outer frame 201 is provided with a stator seat 201a, the stator A hollow shaft tube 201b is arranged upward in the middle of the seat 201a, and a support portion 201c is protruded inwardly from the middle of the inner surface of the hollow shaft tube 201b. The motor bearing structure includes a stator 21, a first ball bearing 22, a second ball bearing Bearing 23 and a rotor 27.

[0015] The stator 21 is fixed on the periphery of the hollow shaft tube 201b, and includes a silicon steel sheet group 211 and a coil group 212 wound on the silicon steel sheet group 211 .

[0016] Both the first bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com