High speed on-line system for testing imbossing seal on cigarette

A detection system and cigarette technology, which are applied to tobacco, measuring devices, manufacturing cigarettes, etc., can solve the problems of large maintenance workload, low work efficiency, incomplete functions, etc., and achieve great promotion and application value, complete detection functions, Stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

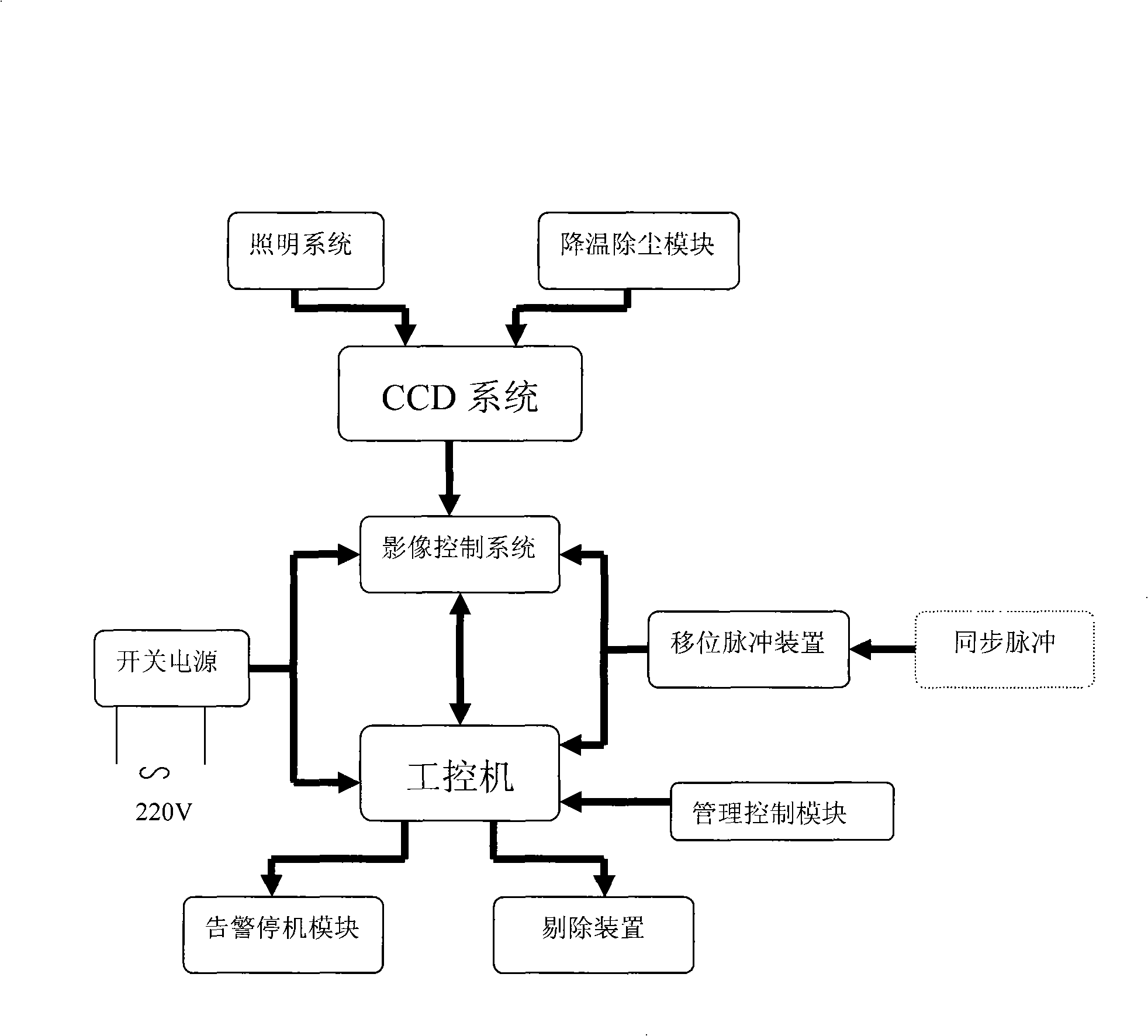

[0007] The technical content of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0008] The invention consists of a CCD system (charge coupler), an illumination system, a cooling and dust removal module, an image control system, an industrial computer, a shifting pulse device, a management control module, an alarm shutdown module, a rejecting device and a switching power supply.

[0009] The concrete function of each constituent part of the present invention is:

[0010] 1. CCD system: real-time shooting of cigarette images printed with stamps in the high-speed cigarette unit one by one;

[0011] 2. Lighting system: provide lighting for CCD system image shooting;

[0012] 3. Cooling and dust removal module: to ensure the long-term stable operation of the CCD system;

[0013] 4. Image control system: realize the analysis and processing of captured image signals and stored standard images, image storage and statistical anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com