Electric pressure cooker

A technology of electric pressure cooker and pot cover, which is applied in the direction of pressure cooker and contact parts, etc., to achieve the effect of safe operation of deflation, improvement of food taste, and easy manufacture and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

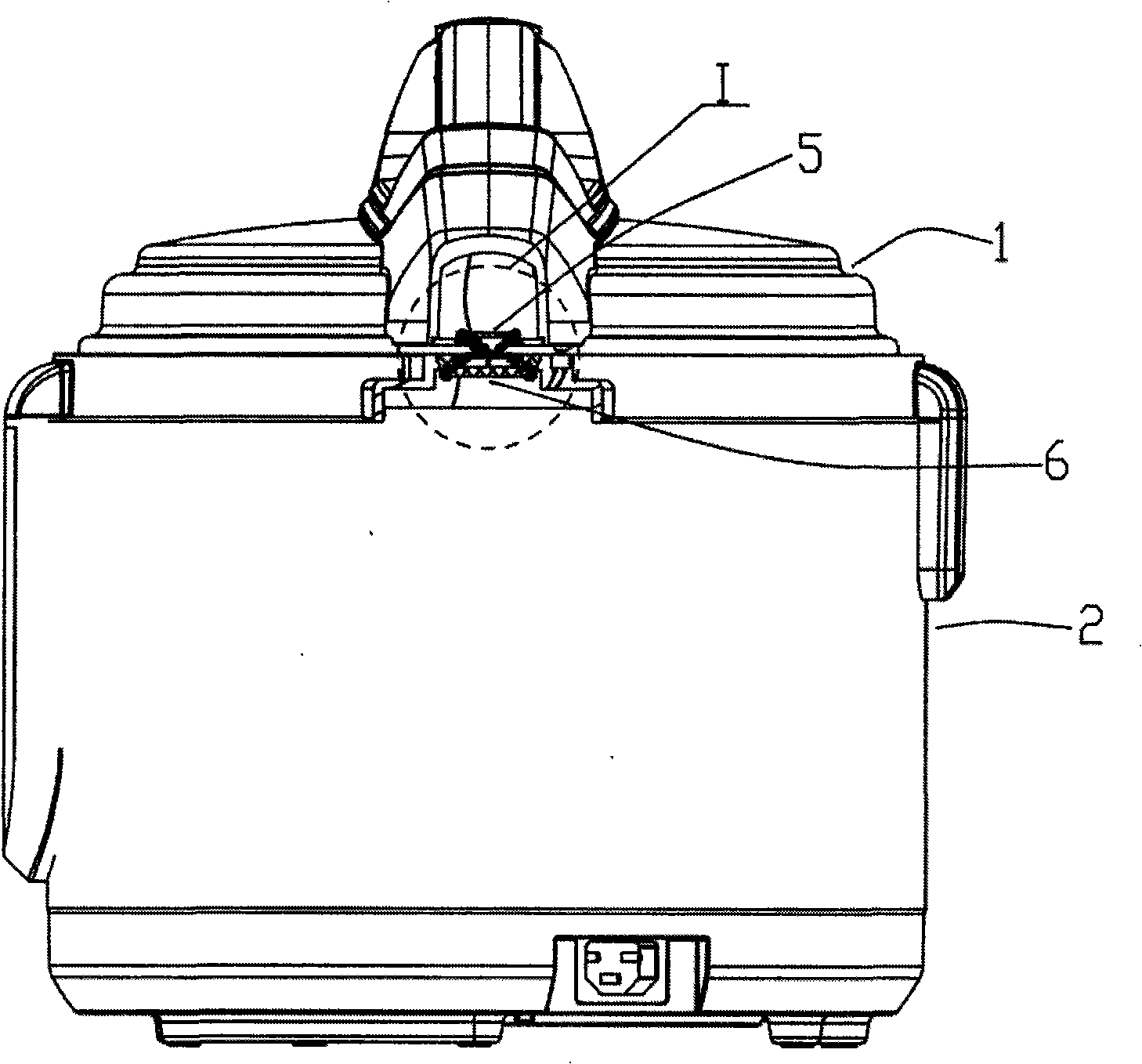

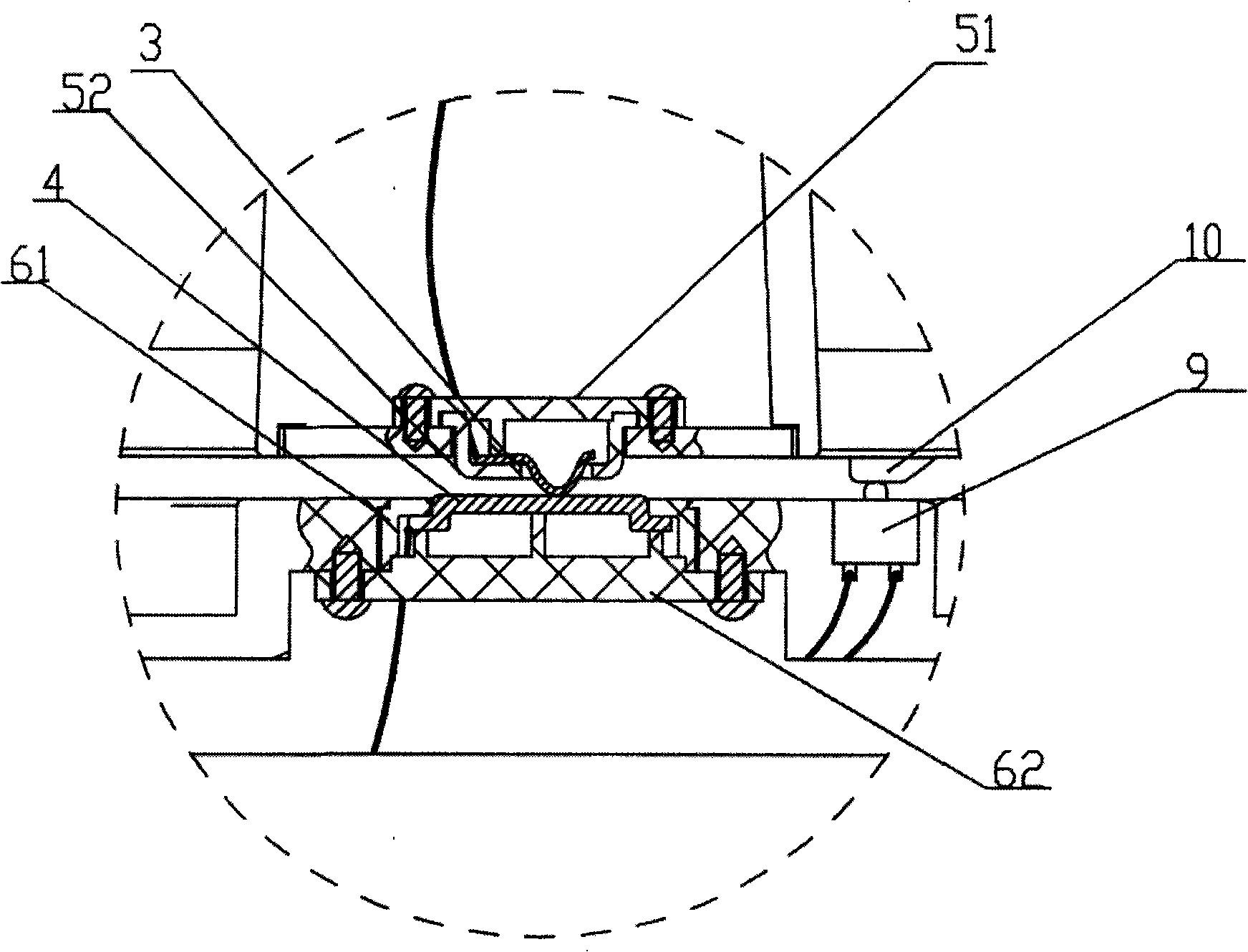

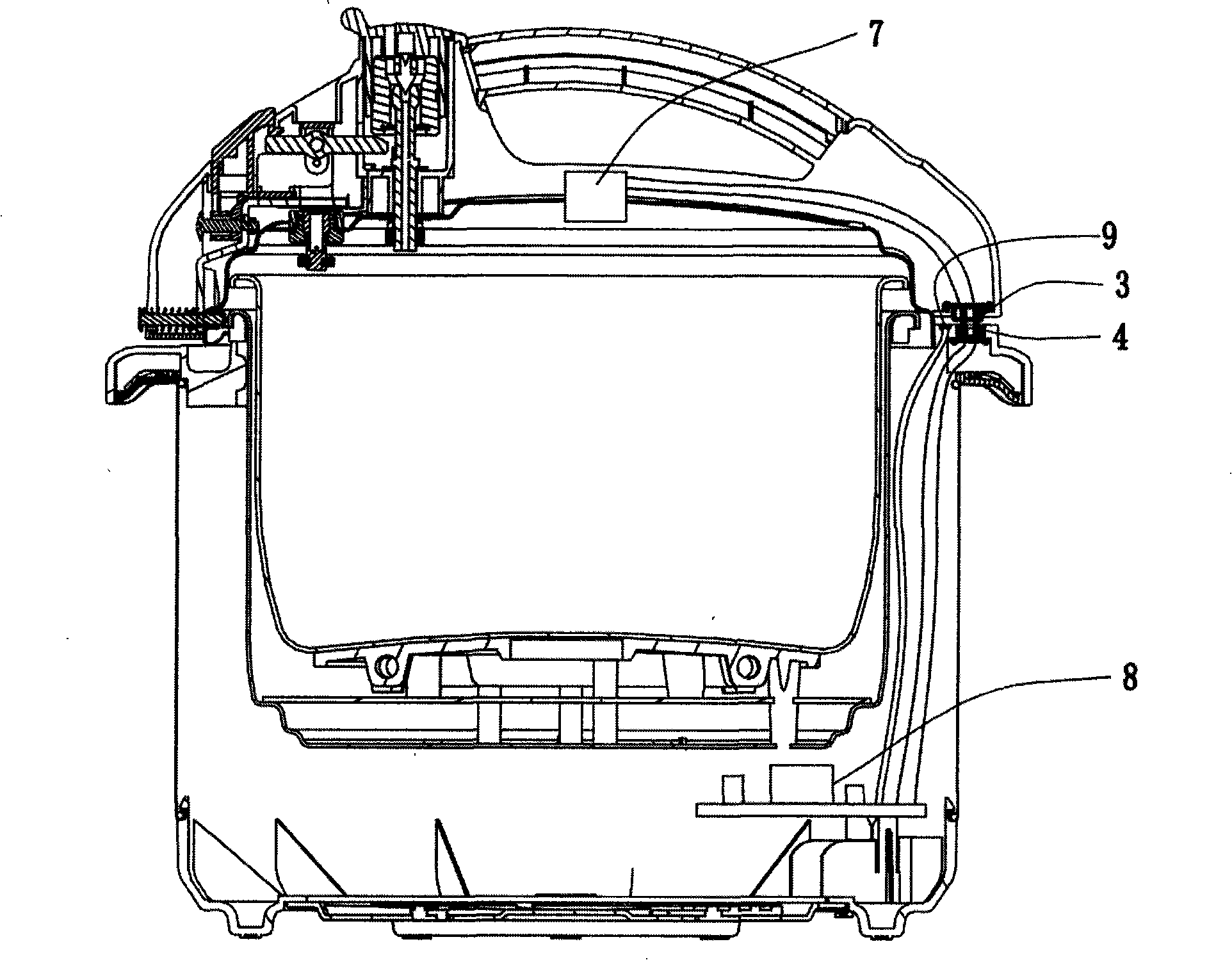

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an electric pressure cooker includes a pot cover 1 and a pot body 2; the pot cover 1 and the pot body 2 are screw-fittedly connected, and an electrical connector is also arranged between the pot cover 1 and the pot body 2, and the electric connector includes 2 One upper contact 3 and two lower contacts 4, wherein the upper contact 3 is an elastic contact, arranged in the accommodating hole on the bottom surface of the pot cover 1, correspondingly, the lower contact 4 is a fixed contact, fixedly installed On top of pot body 2. Both the upper contact 3 and the lower contact 4 are arranged in the horizontal direction.

[0029] The upper contact 3 is an elastic metal sheet, which is fixedly installed in the upper contact fixing box 5. The upper contact fixing box 5 includes an upper contact fixing cover 51 and an upper contact lower cover 52, and the two cooperate to press the upper contact. One...

Embodiment 2

[0036] Such as Figure 6 , Figure 7As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the upper contact 3 is an elastic contact, including a movable metal sheet 31 and a spring 32, and the spring 32 is arranged on the movable metal sheet 31 and the spring Between the supports 33 , one end is against the movable metal sheet 31 , and the other end is arranged in the installation hole provided on the spring support 33 .

[0037] The spring support 33 is fixed on the pot cover 1 by screws, and presses the lower cover 52 to be close to the flange provided on the pot cover 1 .

[0038] The movable metal sheet 31 is freely arranged in the guide groove on the lower cover 52 of the upper contact, and can move up and down. The bottom of the lower cover 52 is provided with an accommodation hole that allows the movable metal sheet 31 to protrude from its bottom surface. When the pot cover 1 and the pot body 2 are screwed tog...

Embodiment 3

[0040] Such as Figure 8 , Figure 9 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the upper contact 3 is a metal plug fixedly installed in the plug fixing box 12, and the plug fixing box 12 is installed on the pot cover 1 by screws The upper and lower contacts 4 are elastic contacts, and the elastic contact is a movable metal sheet, which is installed in the slot 13 on the pot body 2, and the slot 13 is fixed on the pot body 2, between the movable metal sheet and the Compression springs 11 are also installed between the slots 13, and under the action of the compression springs 11, the lower contacts 4 are elastically arranged. When the pot cover 1 and the pot body 2 are screwed together, the upper contact 3 is inserted into the slot 13 in the horizontal direction, and the lower contact 4 is tightly attached to the upper contact 3 under the action of the compression spring 11, so as to facilitate electrical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com