Anti-collision method for pipe body movement, transmission and collecting processes

A technology of anti-collision and pipe body, which is applied in the field of vibration reduction and anti-collision, can solve the problems of non-metallic pipe body anti-collision, high cost of construction and transformation, and difficult maintenance, so as to protect personal health and purify the surroundings The effect of environment, good social benefits and popularization and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

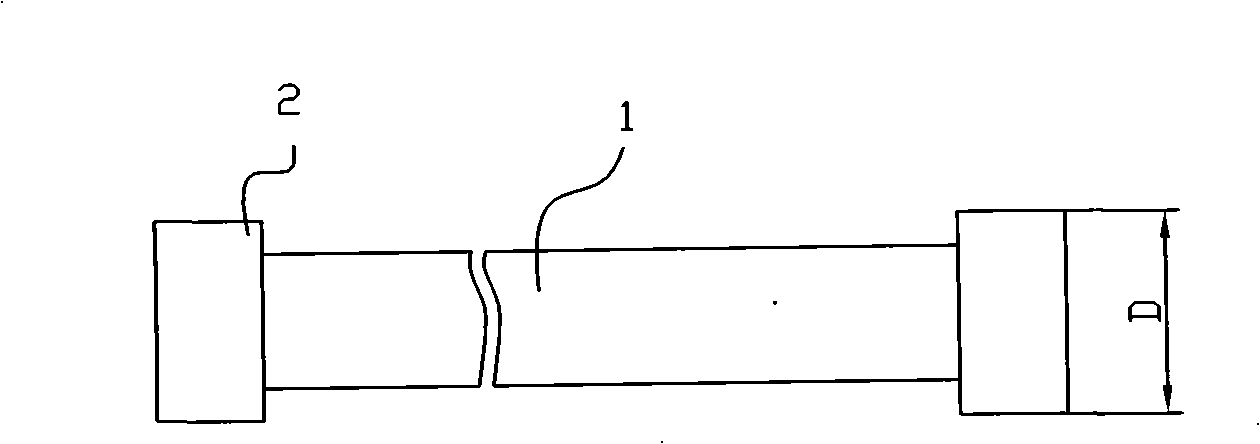

[0030] Rubber, polyurethane, nylon or other plastics are processed into tubular sleeves, which are placed outside the two ends of the pipe body, such as figure 1 As shown, wherein 1 is a tube body, and 2 is a tubular plastic sleeve. Two tubular plastic sleeves are set on the outside of the tube, and follow the movement of the tube without falling off. This embodiment is suitable for anti-collision applications of metallic and non-metallic pipe bodies.

Embodiment 2

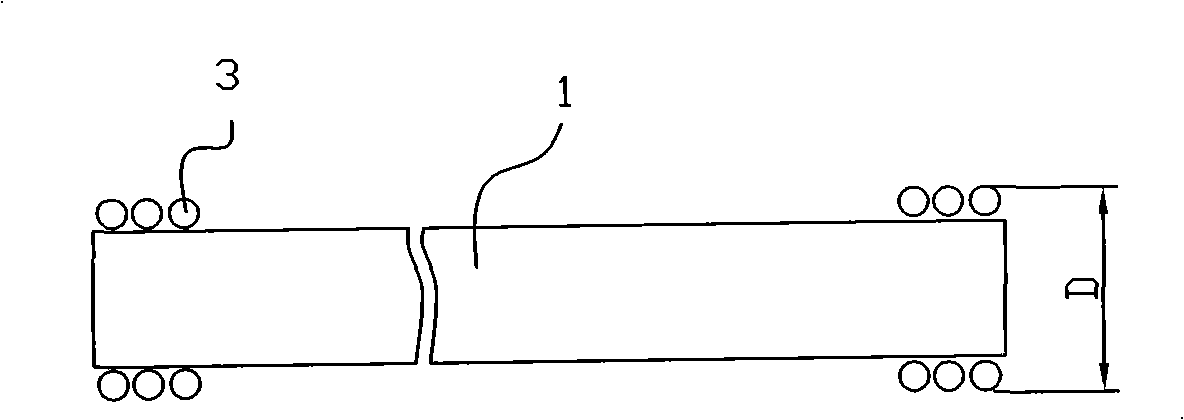

[0032] Mix ferrite magnetic powder or rare earth magnetic powder with rubber, nylon or other plastic particles at a ratio of 1:0.5~5, and add plasticizers, antioxidants, etc. in a plastic extruder to blend and granulate, and then through injection molding After being magnetized, it can be made into magnetic plastic balls or magnetic plastic strips. Magnetic plastic balls or plastic strips rely on their own magnetic force to absorb on the steel pipe surface and not fall off during movement. Such as figure 2 As shown, 1 is a steel pipe, and 3 is a magnetic plastic ball or plastic magnetic strip, wherein the magnetic plastic ball or plastic strip 3 can be adsorbed within a certain length range at both ends of the pipe body, or can be attached to the entire pipe body surface at intervals according to the application. Adsorb several at a certain distance. The size of the magnetic plastic ball or plastic strip 3 is determined according to the length and rigidity of the pipe body....

Embodiment 3

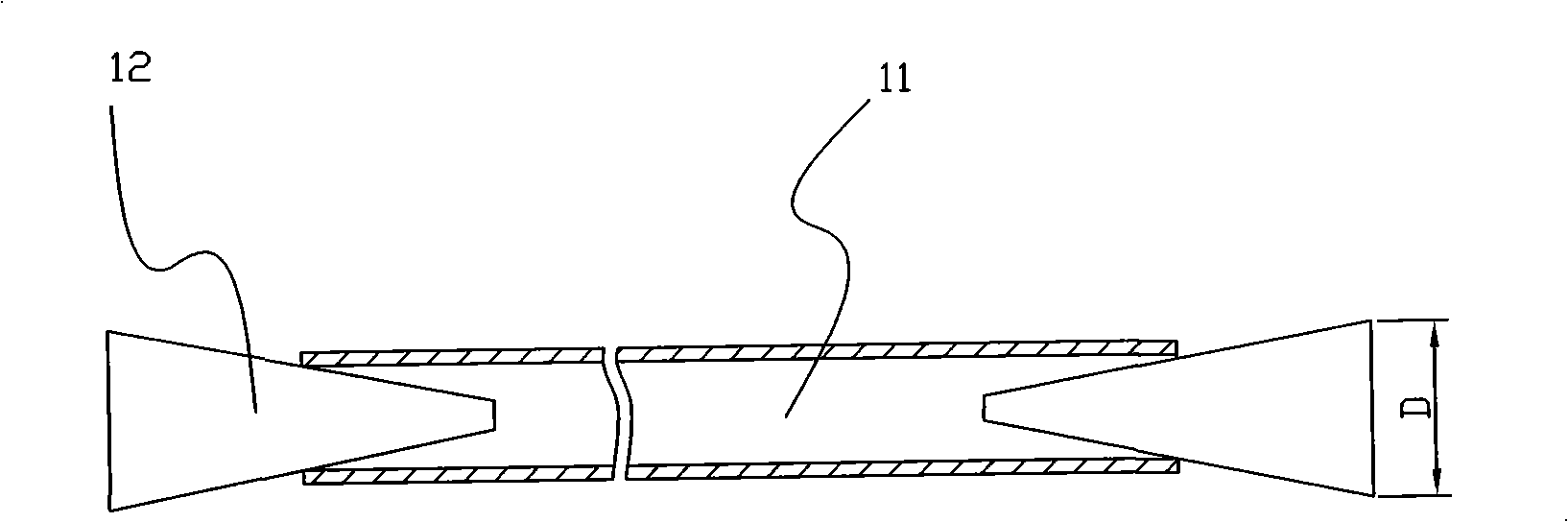

[0036] Rubber, polyurethane, nylon or other plastics are processed into tapered rods, which are inserted into the inner diameter of both ends of the pipe body, such as image 3 Shown, wherein 11 is a pipe body, and 12 is a tapered plastic rod. The tapered plastic rod 12 can be solid or hollow, and it is required to be inserted into the inner diameter of the pipe to follow the movement and not come off. The maximum profile dimension D of the tapered plastic rod 12 is required to be larger than the maximum outer diameter of the pipe body, and is determined according to the length and rigidity of the pipe body. This implementation is suitable for crashworthy applications of metallic and non-metallic pipe bodies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com