City track traffic U type beam

An urban rail transit, U-shaped technology, applied to bridges, buildings, etc., can solve the problems of unsafe walking and poor safety protection for maintenance personnel, and achieve the effects of reducing noise pollution, high space utilization, and reducing the height of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

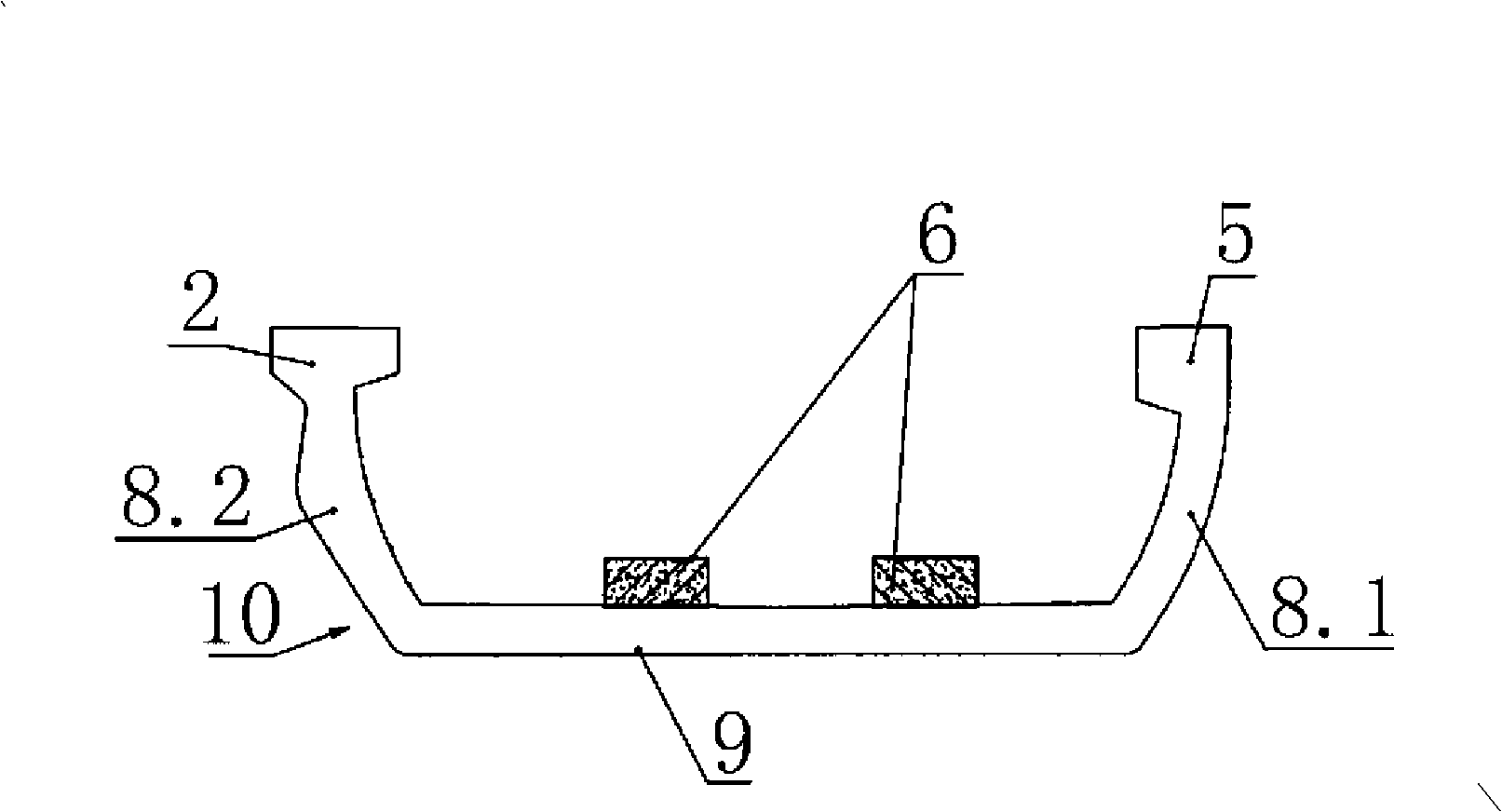

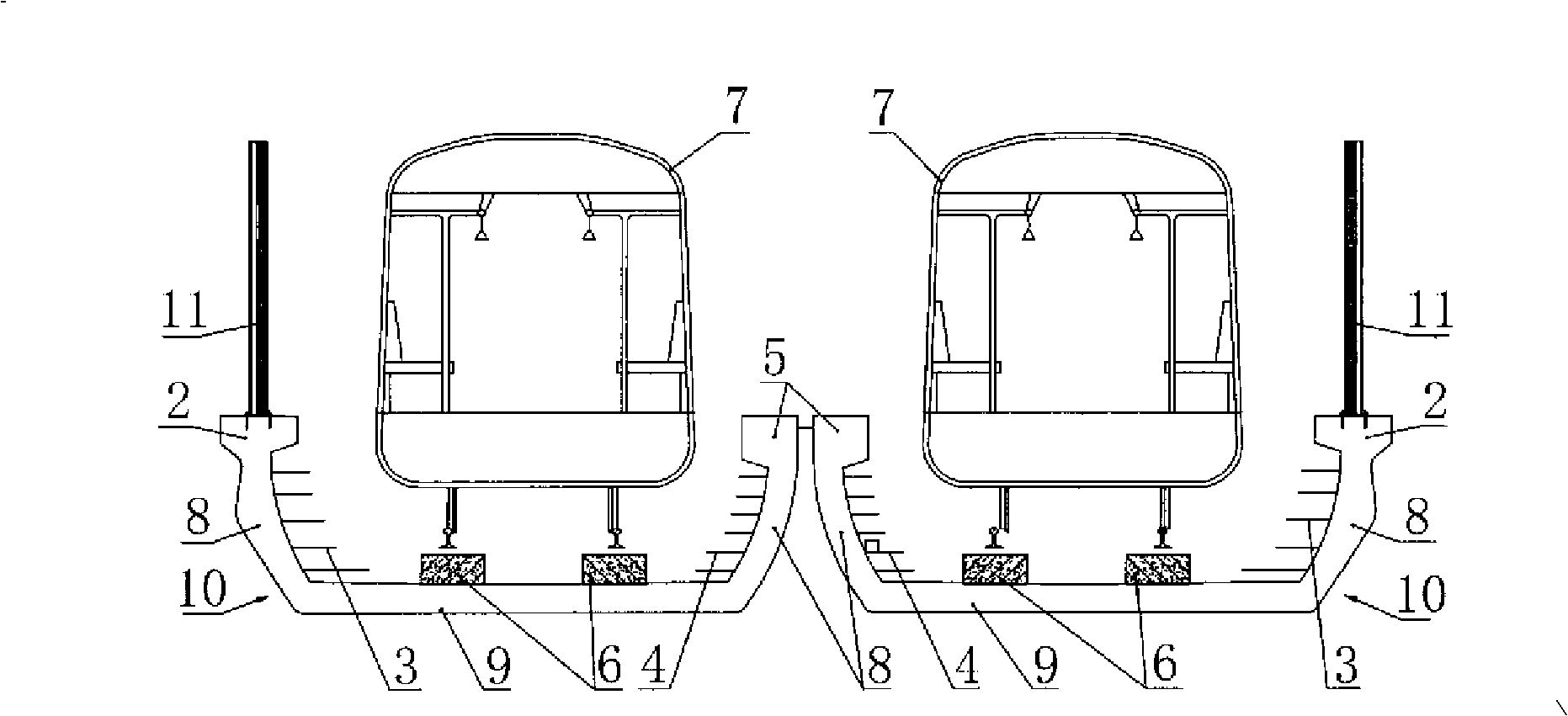

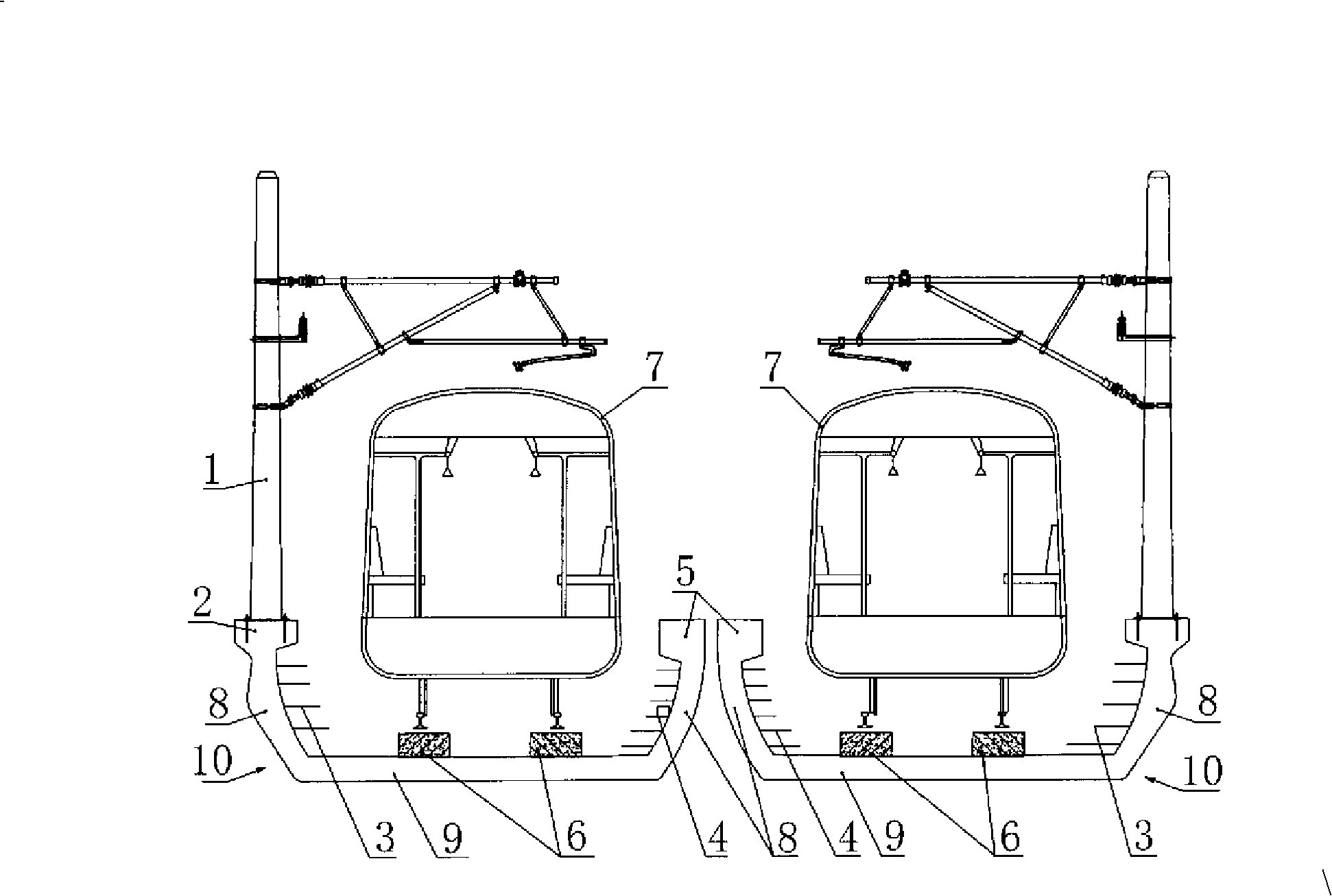

[0028] Embodiment one sees figure 1 , figure 2 , image 3 , as shown, in this U-shaped beam of urban rail transit, the beam body 10 is connected by the bottom plate 9, the webs 8 on both sides and the flange plate on the top of the web to form a U-shaped cross-section channel, and the upper surface of the bottom plate 9 is connected to the bearing The rail platform 6 and the train 7 run on the rail platform 6. The power supply device, the power supply cable support body 3 and the communication signal cable support body 4 are fixedly connected along the beam body lengthwise. concrete structure. The webs 8 on both sides are asymmetrical, one side of which is a curved web 8.1 with equal wall thickness, and the flange plate connected to the top of the side web is a 7-shaped flange plate 5, that is, only the inward Flange; the other side is the convex, smooth and thickened curved web 8.2 with unequal wall thickness on the outside of the middle and upper section, and the flange ...

Embodiment 2

[0030] Embodiment two see Figure 4 , and the difference from the first embodiment is that the power supply device is a three-rail power supply device 12 provided on the base plate 9 .

Embodiment 3

[0031] Embodiment three see Figure 5 , Image 6 , The U-shaped beam is a double U parallel shape, and the double U-shaped beams share the same bottom plate. The U-shaped beam and the cover beam 13 are connected as a whole. The catenary column 1 is placed on the T-shaped flange plate 2 . The communication signal cable support body 4 is located between two pairs of rail platforms 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com