Antifreeze fluid built-in type differential pressure transfer control valve

A built-in, control valve technology, applied in the valve's device for absorbing fluid energy, lift valve, valve details, etc., can solve the problem of valve freezing, affecting the safety of liquid supply and automation, and user loss, etc., to eliminate The effect of liquid strike and automatic control of sealing and non-return without external power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

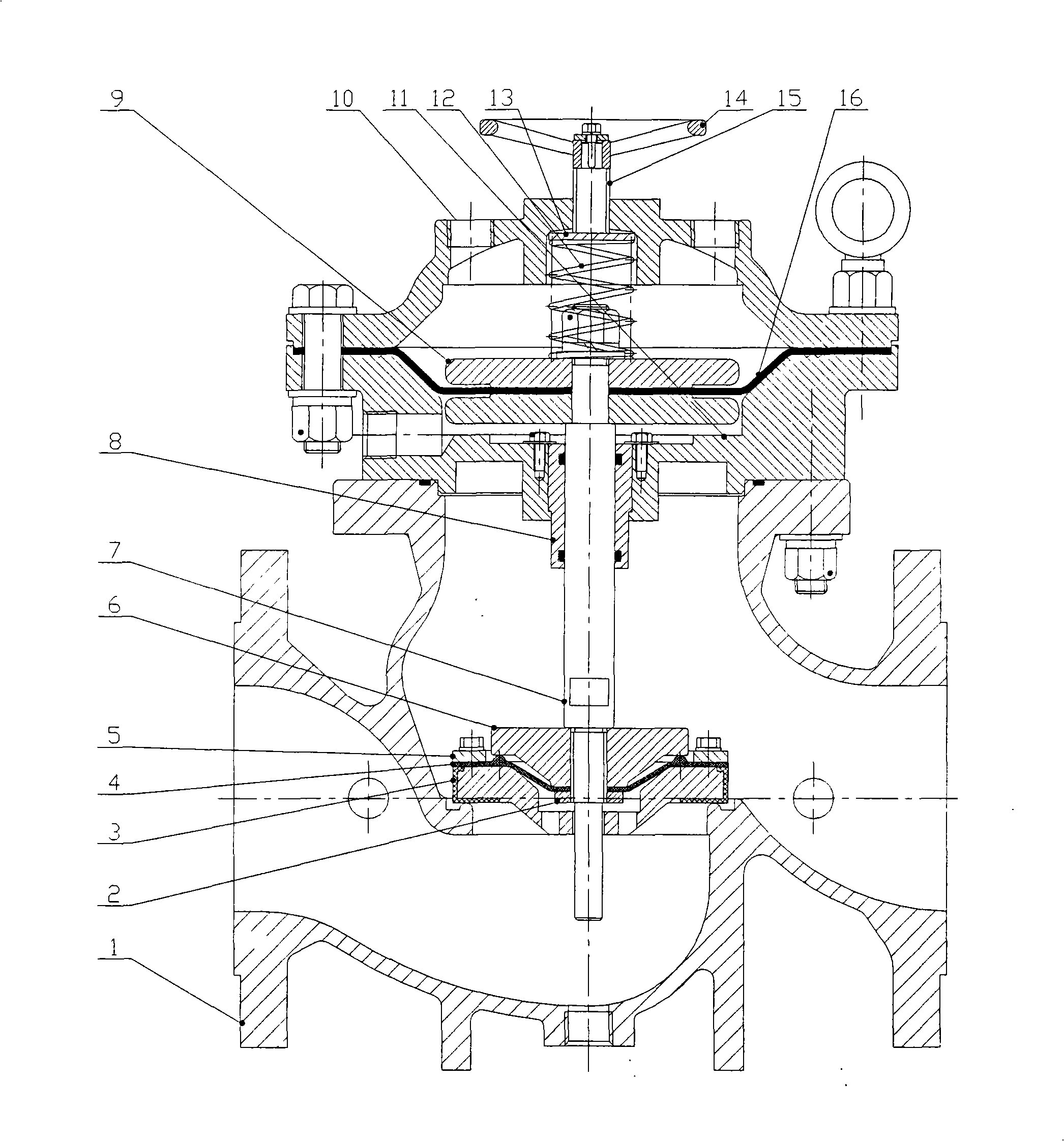

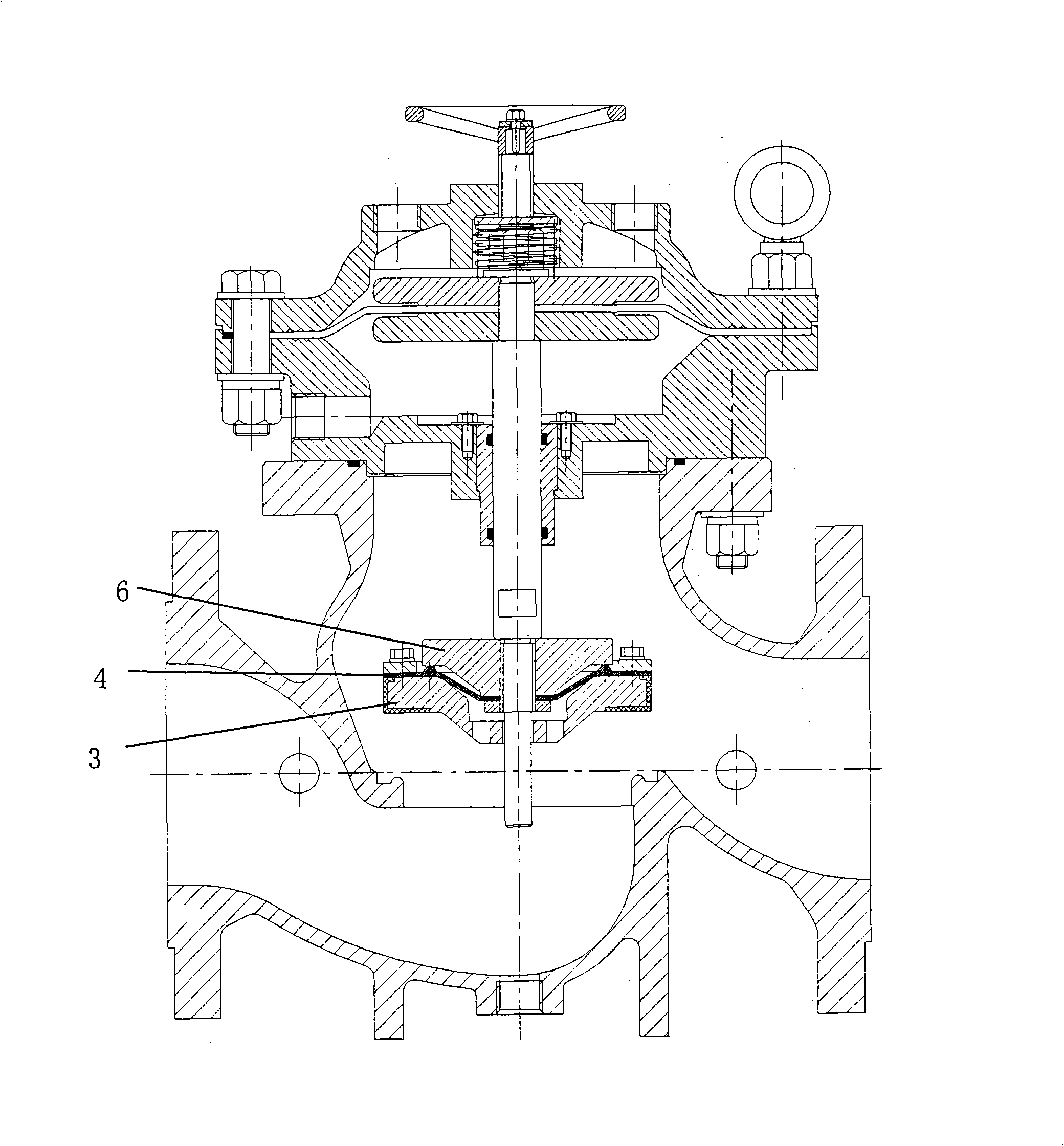

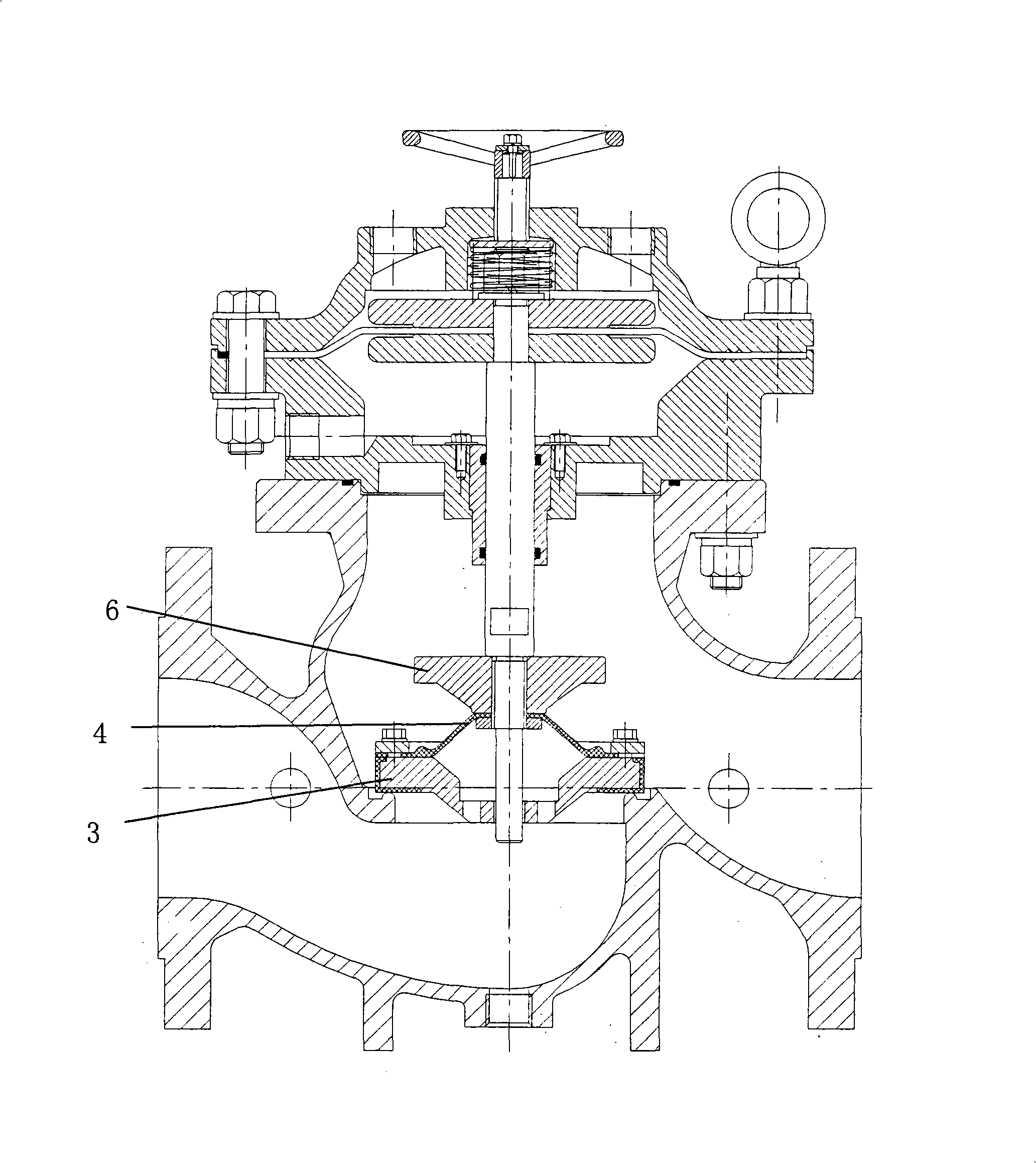

[0016] The structure of the antifreeze fluid built-in differential pressure transmission control valve of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0017] Such as figure 1 As shown, the antifreeze type fluid built-in differential pressure transmission control valve of the present invention is composed of a valve body and a valve core. The valve body includes a hand wheel 14, a screw rod 15, an upper valve cover 10, a lower valve cover 11, and a valve body 1. The spool includes a backing plate 9, a valve stem 7, a small valve plate 6, a lower diaphragm 4, and a large valve plate 3. When the pump is turned on, the gate can be closed and opened slowly. When the pump is stopped, because there is a flexible connection lower diaphragm 4 with holes between the small valve plate 6 and the large valve plate 3, the pressure relief of the backflow liquid can be realized, and pressure can be generated. Poor, drive the valve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com