Photocurable resin composition

A technology of photocurable resin and composition, which is applied in the field of photocurable resin composition and cured body, can solve the problems of unknown vibration fatigue durability resin composition, etc., and achieve excellent vibration fatigue durability and excellent fatigue resistance characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

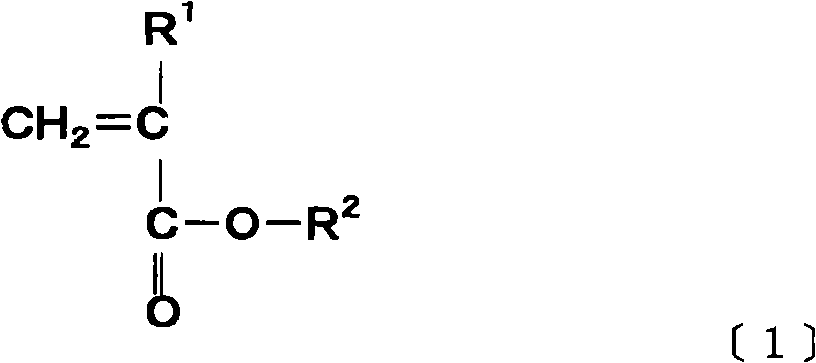

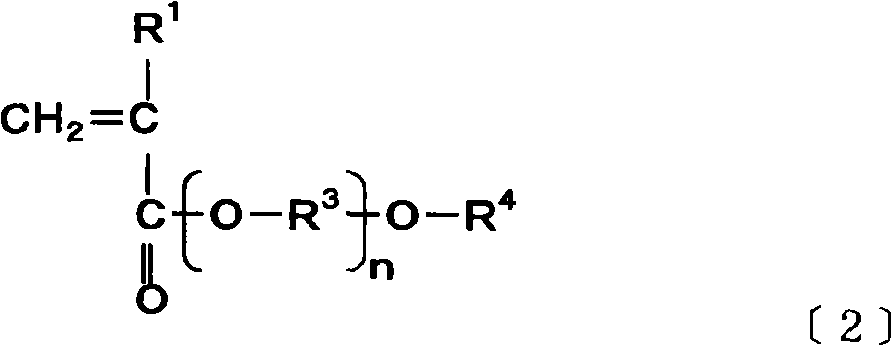

Method used

Image

Examples

Embodiment 1~17 and comparative example 1~7

[0149] Hereinafter, each component of the kind shown in Table 1-1, Table 1-2, and Table 1-3 was mixed according to the composition (weight%) shown in a table|surface, and the photocurable resin composition was prepared.

[0150] In addition, the following compounds were selected as each component in the compounding composition described in the Example and the comparative example.

[0151] As (A) component,

[0152] (A-1) Polyester polyol polyurethane acrylate

[0153] (Nippon Synthetic Chemical Industry Co., Ltd. product name UV-3000B)

[0154] (The weight average molecular weight of polystyrene measured by GPC is 18000)

[0155] (A-2) Polyether polyol polyurethane acrylate

[0156] (Nippon Synthetic Chemical Industry Co., Ltd. product name UV-3700B)

[0157] (The weight-average molecular weight converted to polystyrene measured by GPC is 37000)

[0158] (A-3) Polyester polyol polyurethane acrylate

[0159] (Negami Industry Co., Ltd. product name KHP-11)

[0160] (The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com