Hot-dip galvanized steel sheet

A technology of hot-dip galvanized steel sheet and hot-dip galvanized steel, applied in the field of hot-dip galvanized steel sheet and high-strength hot-dip galvanized steel sheet, can solve the bad influence of Si-Mn oxide coating adhesion, Si-Mn oxide coating There are no problems such as disclosure of oxides, and the effects of excellent plating adhesion and corrosion resistance are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0262] Hereinafter, examples of the present invention will be described. In addition, the conditions in this example are an example of conditions adopted in order to confirm the practicability and effects of the present invention. The present invention is not limited to this conditional example. In the present invention, various conditions can be adopted as long as the object of the present invention is achieved without departing from the gist of the present invention.

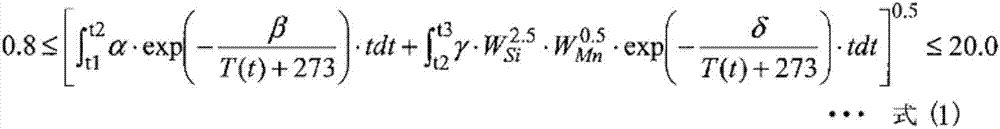

[0263] Slabs having chemical components (compositions) of A to BY shown in Tables 1 to 6 were cast, and hot rolled under the conditions (slab heating temperature, rolling completion temperature) shown in Tables 7 to 10. Next, cooling was performed under the conditions shown in Tables 7 to 10 (average cooling rate from completion of hot rolling to coiling, coiling temperature, formula (1)) to obtain hot-rolled steel sheets.

[0264] Thereafter, the hot-rolled steel sheets were pickled, and cold-rolled under t...

experiment example 190

[0352] Experimental Example 190 is an example in which the content of C was small, the volume fraction of the hard phase was small, and sufficient strength, ductility, and hole expandability were not obtained.

experiment example 191

[0353] Experimental example 191 is an example in which the content of C is large and the spot weldability deteriorates. In addition, the fraction of martensite increases, and fatigue resistance, ductility, hole expandability, and bendability are inferior.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com