Ethylene-acrylate rubber formula for turbocharging rubber pipes

A turbocharged, acrylic technology, applied in the field of rubber materials, to achieve excellent fatigue resistance, improve safety and practicality, and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

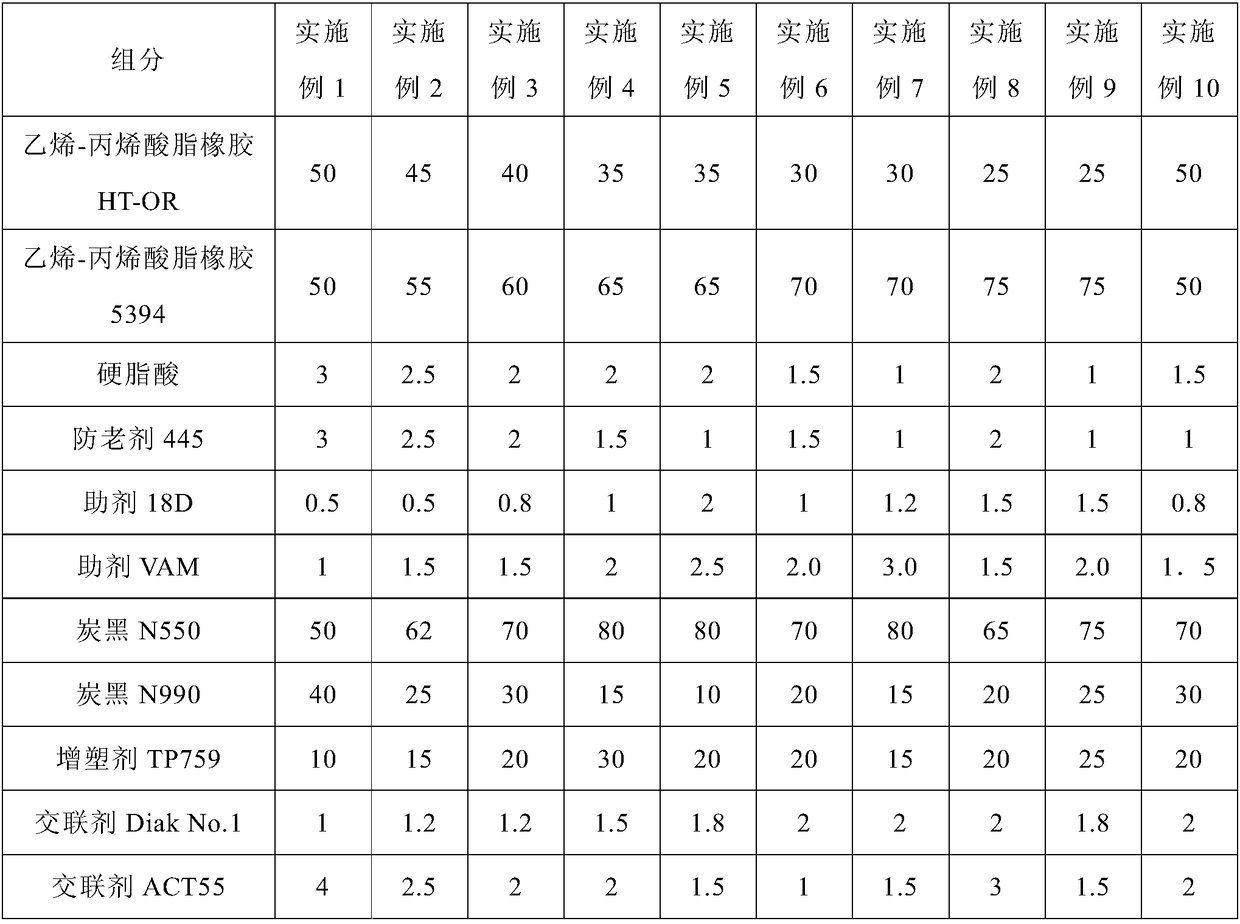

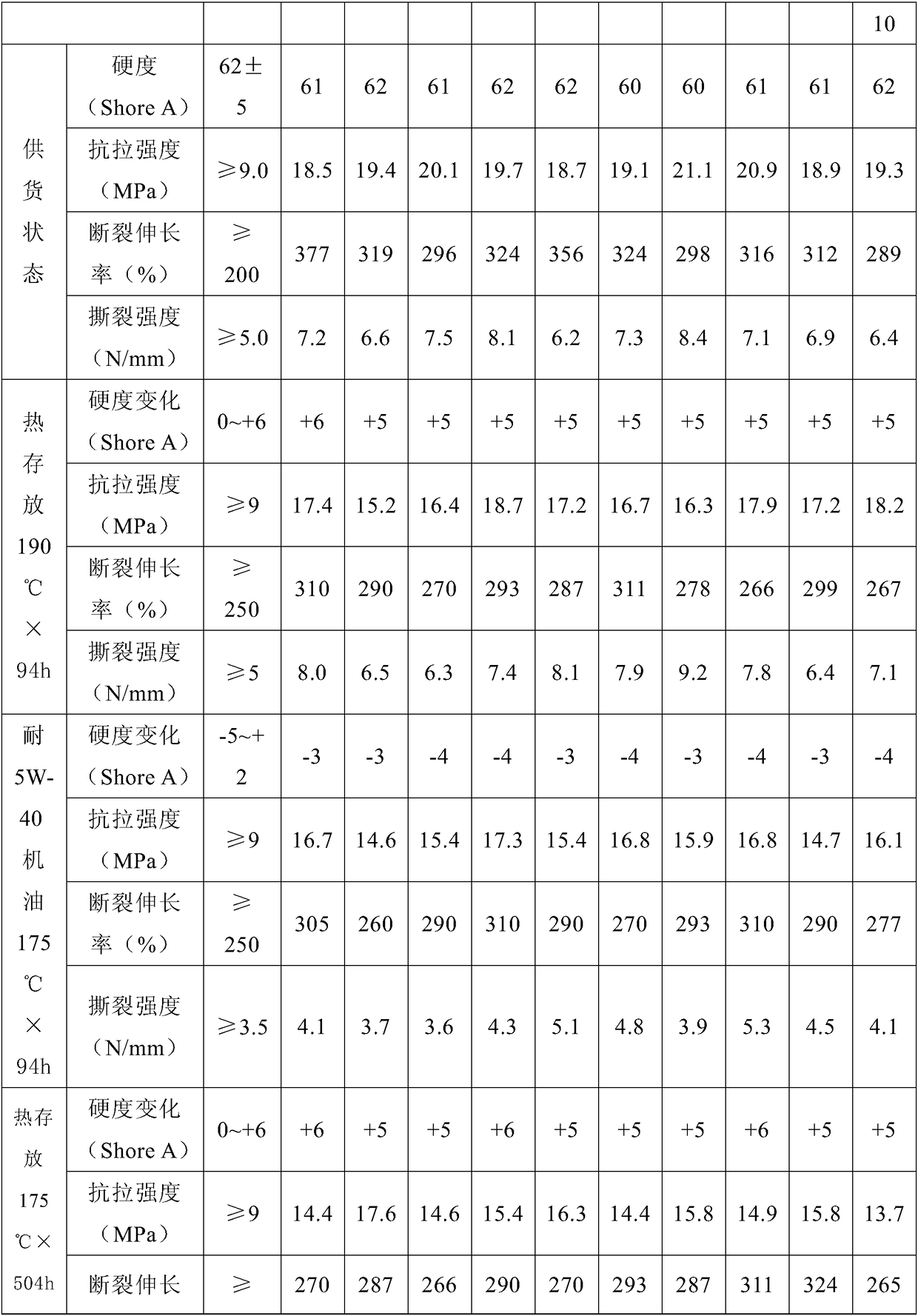

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific examples.

[0009] The mixing process of ethylene-acrylate rubber turbocharger hose is carried out according to the following steps:

[0010] (1), weighing

[0011] Weigh the following raw materials: 25-50 parts by weight of ethylene-acrylate rubber HT-OR, 50-75 parts by weight of ethylene-acrylate rubber 5394, 1-3 parts by weight of stearic acid, 1-3 parts by weight of anti-aging agent 445 Parts by weight, 0.5-2 parts by weight of auxiliary agent 18D, 1-3 parts by weight of auxiliary agent VAM, 50-80 parts by weight of carbon black N550, 10-40 parts by weight of carbon black N990, 10-3 parts by weight of plasticizer TP759 30 parts by weight, 1-4 parts by weight of the cross-linking agent ACT55, and 1-2 parts by weight of the cross-linking agent Diak No.1.

[0012] (2), and glue

[0013] Put the ethylene-acrylate rubber HT-OR and ethylene-acrylate rubber 5394 weighed according to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com