Rubber composition for tread

A technology of rubber composition and tread, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of insufficient dispersion, large primary particle size, and insufficient performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

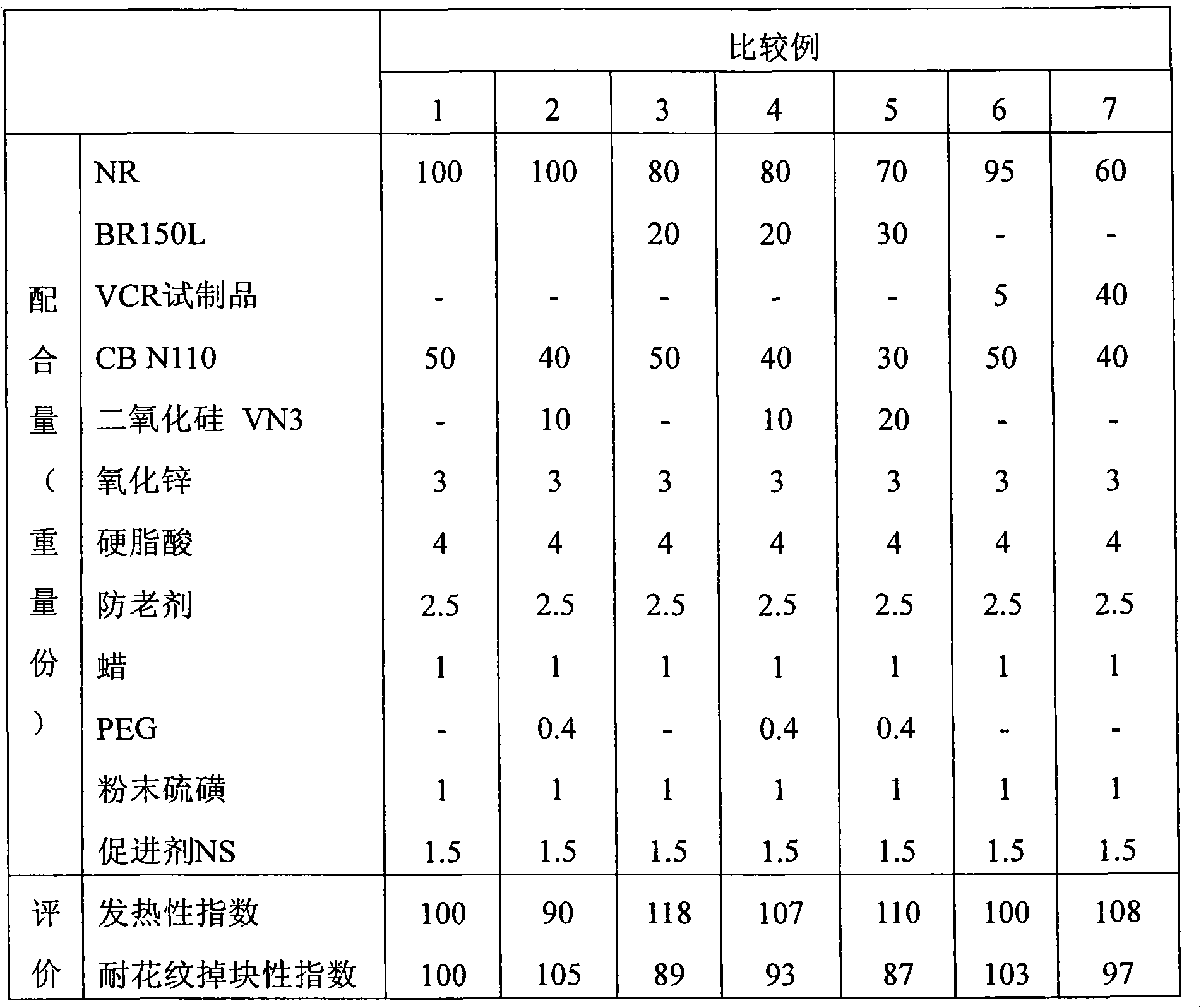

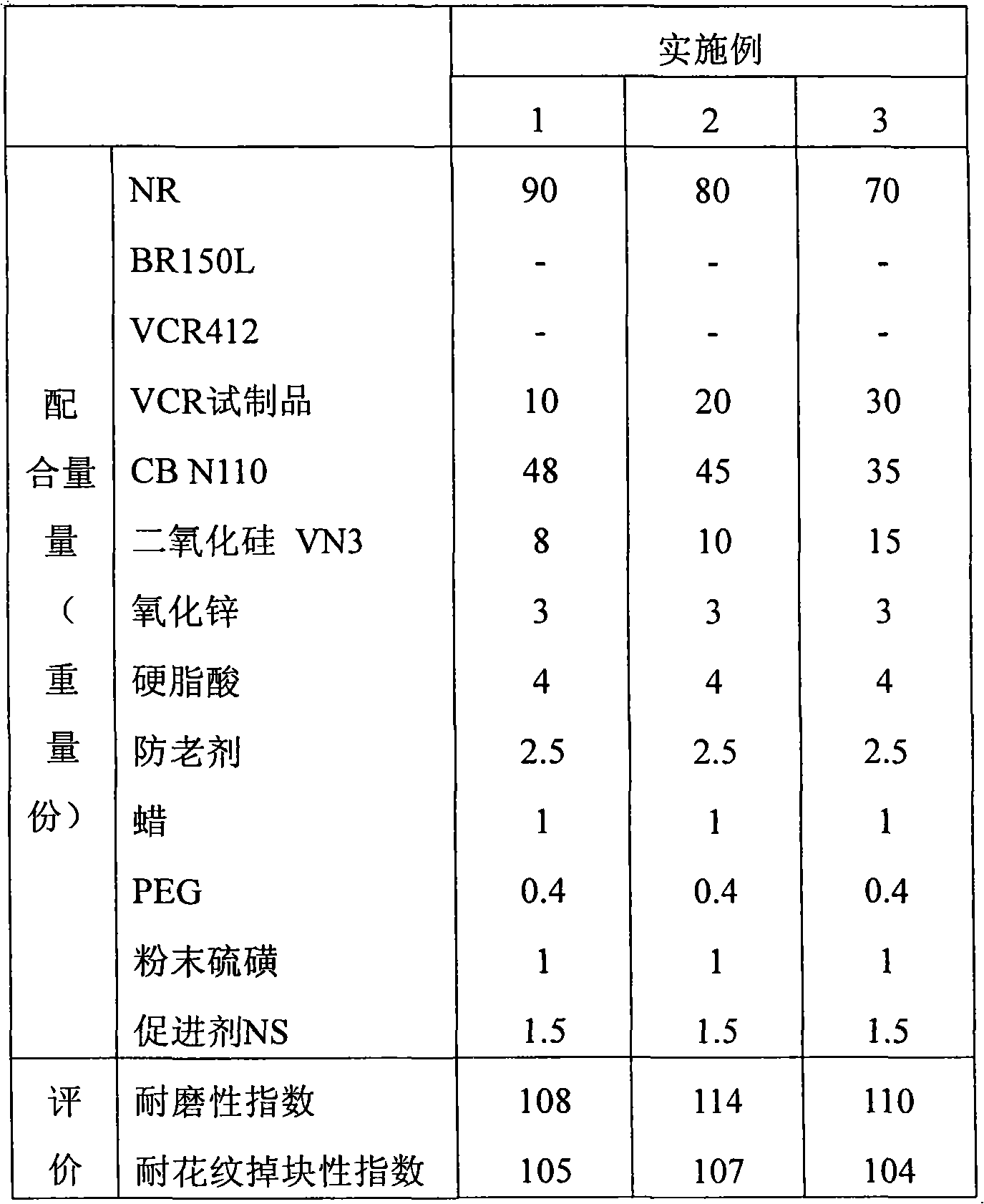

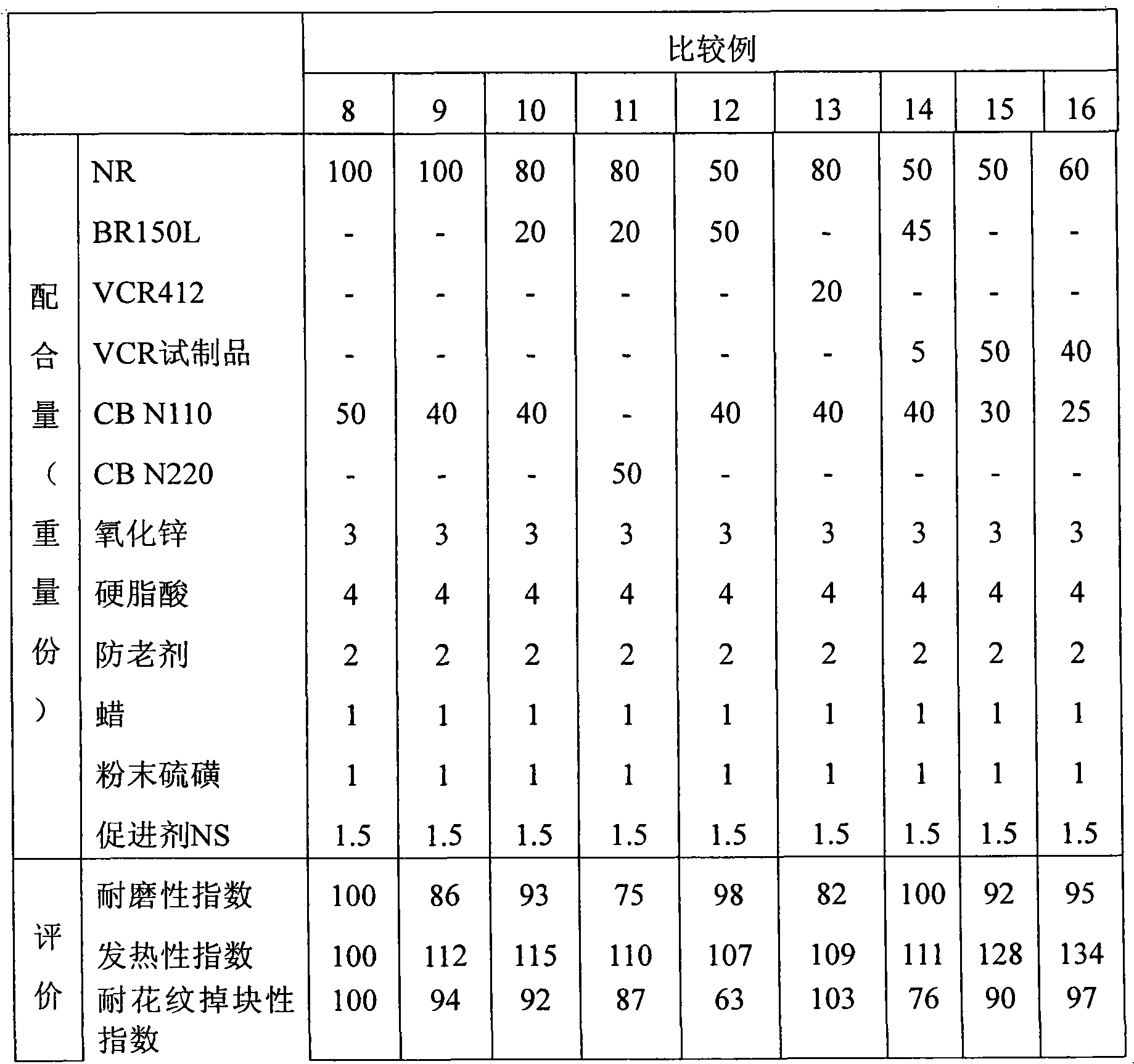

Embodiment 1~7 and comparative example 1~16

[0069] (Manufacturing method of test tire)

[0070] According to the compounding contents in Tables 1 to 4, the above-mentioned compounding ingredients except sulfur and vulcanization accelerator were mixed in a Banbury internal mixer under the conditions of a maximum mixing temperature of 150°C and a mixing time of 4 minutes.

[0071] Next, add sulfur and a vulcanization accelerator, knead using an open mill at a kneading temperature of 40 to 60° C. and a kneading time of 4 minutes, and extrude into a rubber sheet using an extruder.

[0072] By molding the obtained rubber sheet into the shape of a tread, laminating it with other tire components, and vulcanizing it at 150° C. for 35 minutes, the test tires of Examples 1 to 7 and Comparative Examples 1 to 16 (tire size 11R22 .5) for the following determination tests.

[0073]

[0074] Using a test piece cut from a test tire, using a Lamborn abrasion tester (manufactured by Iwamoto Seisakusho), the test time is 5 minutes, the...

Embodiment 8~12 and comparative example 17~26

[0099] (Manufacturing method of studless tire for test)

[0100] According to the compounding contents in Tables 5 and 6, mix the above-mentioned compounding ingredients except sulfur and vulcanization accelerator at the mixing temperature

[0101] Under the conditions of 150° C. and a kneading time of 4 minutes, kneading was performed by a Banbury internal mixer.

[0102] Next, add sulfur and a vulcanization accelerator, use an open mill, and knead with a kneading temperature of 40-60°C and a kneading time of 4 minutes

[0103] Mixing is carried out under certain conditions, and extruded into rubber sheets using an extruder.

[0104] The obtained rubber sheet was molded into the shape of the tread, bonded to other tire parts, and vulcanized at 150° C. for 35 minutes to prepare the test studless tires of Examples 8 to 12 and Comparative Examples 17 to 26 (tire size 11R22.5), used for the following determination tests.

[0105]

[0106] A test piece was cut out from the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com