Reversing valve

A technology of switching valve and locking element, applied in the field of switching valve, can solve problems such as leakage and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

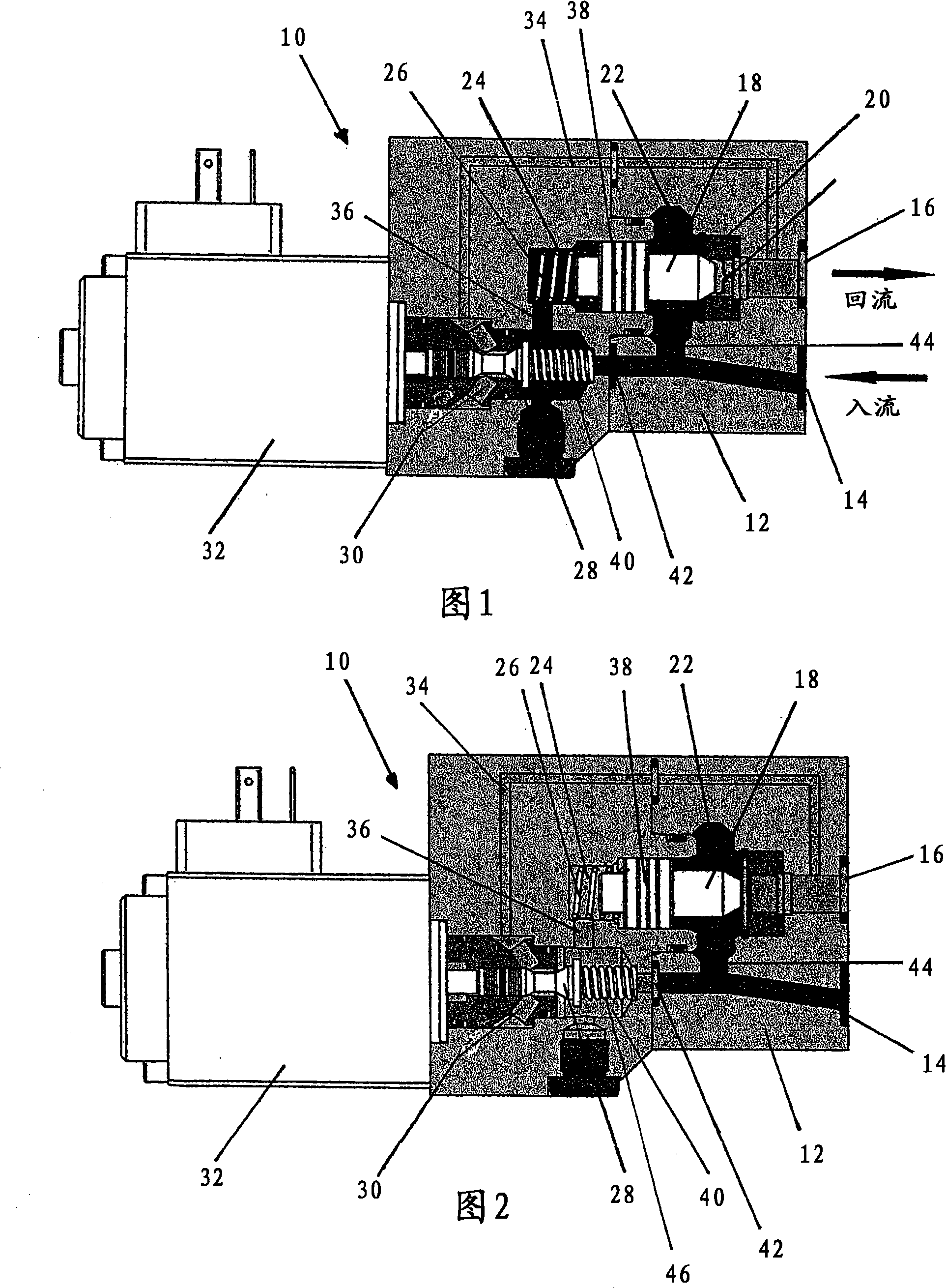

[0021] The switching valve 10 shown in FIGS. 1 and 2 includes a housing 12 which, for better assembly, can be designed in two parts, as shown in FIGS. 1 and 2 . An inlet 14 and an outlet 16 are shown in the housing 12 . Fluid (inflow) from a high pressure source (dosing device) merges into the inlet 14 . Pressures in the range up to 250 bar and higher occur here. The return flow is connected to a mixing head, not shown here. The pressure in the reflux can vary within a range from a pressure level slightly lower than that of the inflow up to a few bar range (eg 8 bar).

[0022] A chamber is formed in the housing 12, in which chamber a reciprocating movement (to the left and right in FIGS. 1 and 2) is accommodated a lock valve 18 on which a piston 38 is integrally formed. In this case, the piston 38 is dimensioned in such a way that it closes the chamber in a wall-tight manner, so that a variable-sized active chamber is formed on both sides of the piston 38 . The first activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com