Sealing method of cabinet

A technology for cabinets and sealing strips, applied in furniture parts, applications, household appliances, etc., can solve problems such as difficult to meet sealing requirements, and achieve the effect of solving cabinet sealing problems, low cost, and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

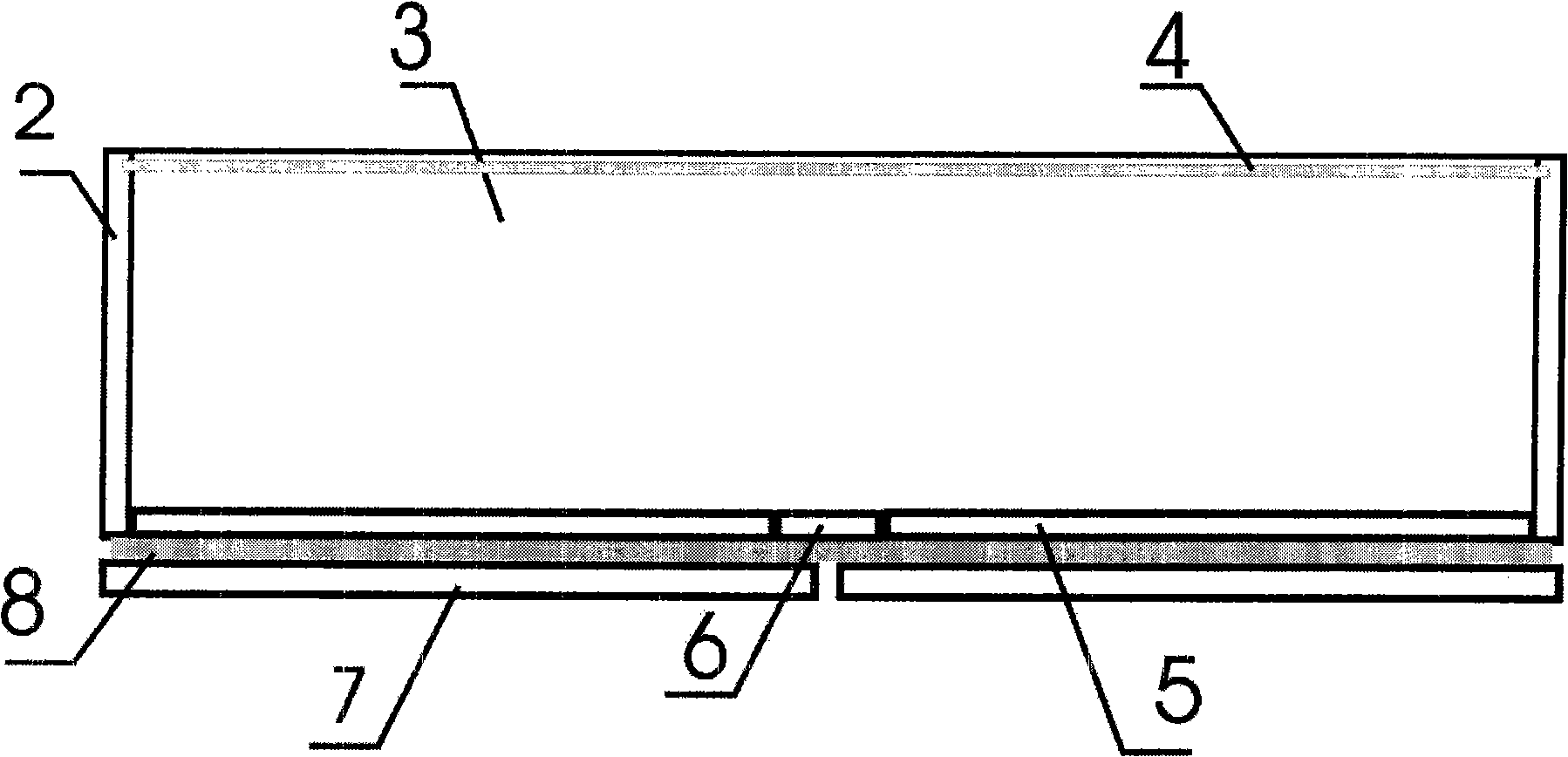

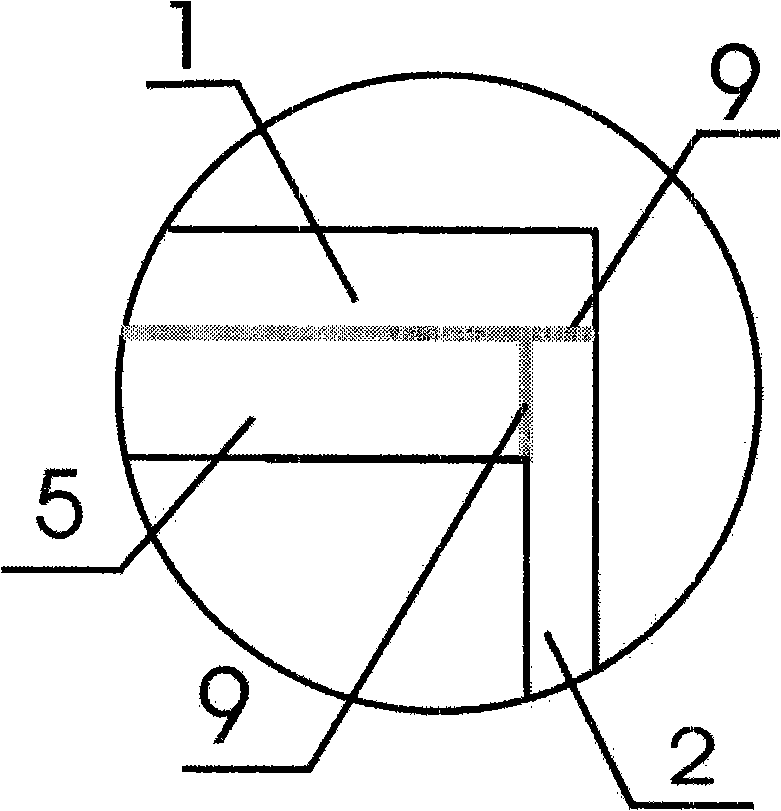

[0027] In practical application, since the structure of the cabinet body has various structures and combinations, it is only necessary to apply sealant or stick a sealant on the joints of each cabinet board, and then assemble the cabinet body. Such as Figure 4 shown. When installing the cabinet door, first install the sealing strip at the position where the front of the cabinet body is in contact with the door, and then install the cabinet door so that the door and the cabinet body are closely combined. The local structure is as follows: Figure 5 shown. For the sake of the beauty of the cabinet body, to avoid revealing the sealant or sealant stickers, when processing the cabinet body, it is possible to reserve installation slots for installing sealant or sealant stickers at the joints of each cabinet board.

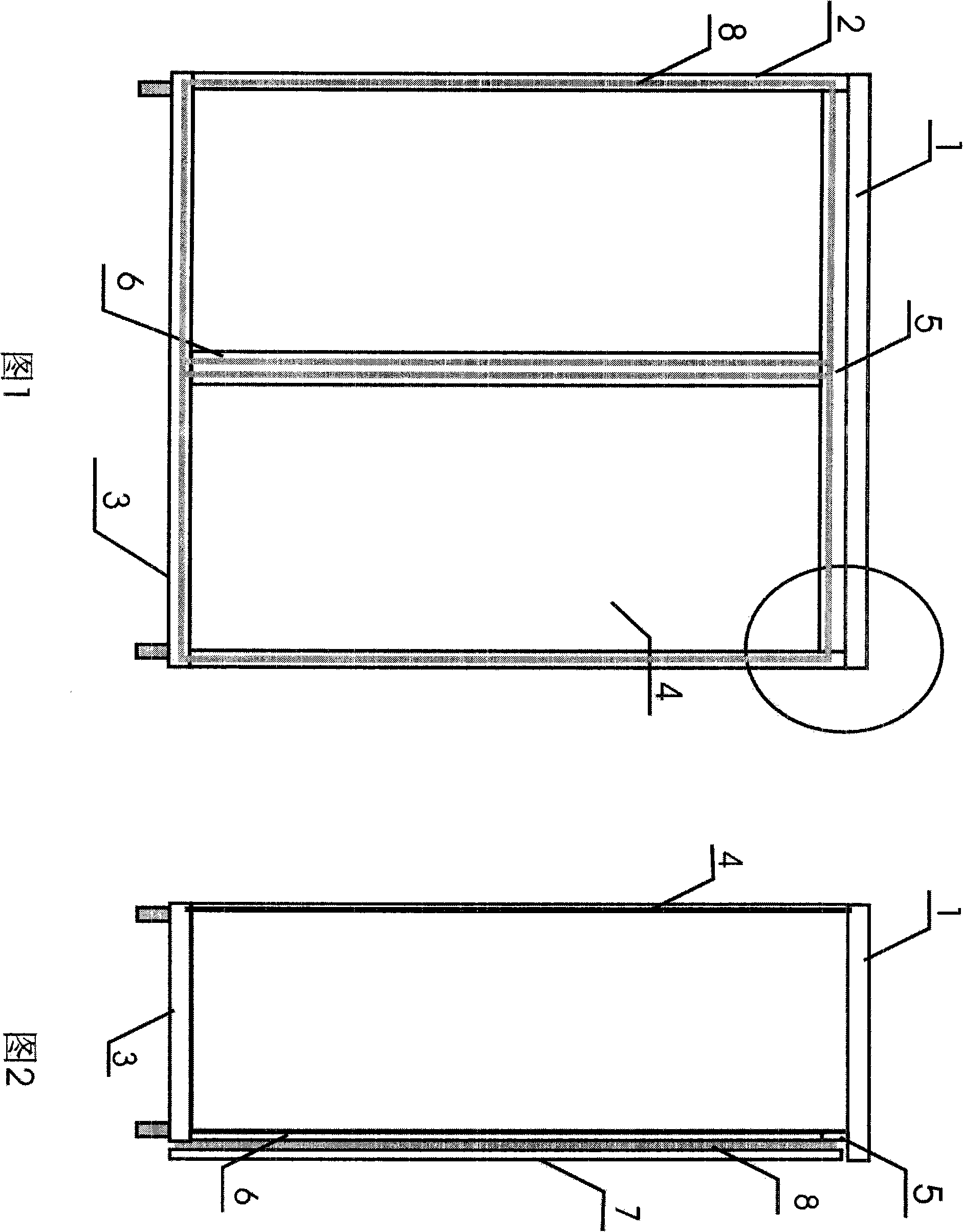

[0028] Combined with Figure 1, Figure 2, image 3 Explain the sealing method of the cabinet door upper baffle and the cabinet door center column baffle, the front ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com