Iron ring processing device

A technology of processing device and iron ring, applied in the direction of metal processing equipment, etc., can solve the problems of long processing process, many equipments, high cost, etc., to achieve the effect of no material loss and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

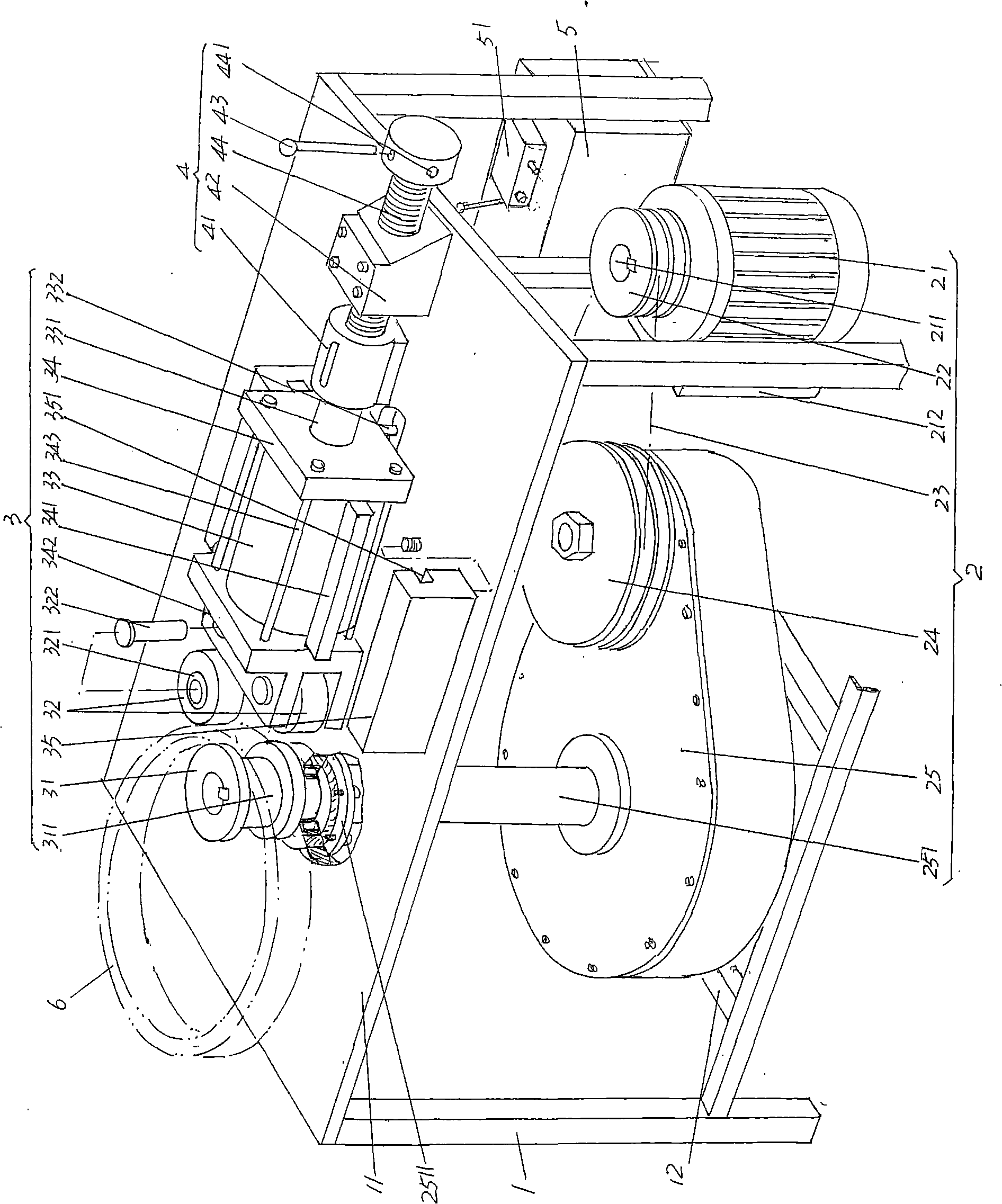

[0016] Please refer to the attached drawings. A frame 1 with a work surface 11 supported by more than one leg is shown. A joist 12 is provided near the bottom of the frame 1. The power transmission mechanism 2 is arranged at the lower part of the frame 1 and corresponds to the bottom of the work surface 11. The motor 21 as the power transmission mechanism 2 is fixed to the frame 1 through the motor fixing base 212, and the first transmission is fixed on the motor shaft 211 of the motor 21 Wheel 22, one end of the transmission belt 23 is sleeved on the first transmission wheel 22, and the other end of the transmission belt 23 is sleeved on the second transmission wheel 24. The power of the second transmission wheel 24 and the reduction box 25 installed on the joist 12 The input shaft is fixed, and the upper end of the power output shaft 251 of the reduction box 25 is pivoted with the work surface 11 through the bearing seat 2511, that is, is supported on the work surface 11 and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com