Efficient sealing continuous graphitization furnace

A graphitization furnace, high-efficiency technology, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of inability to achieve sealed operation, poor workshop working environment, low power utilization rate, etc. Effective cooling effect, volatile emission and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

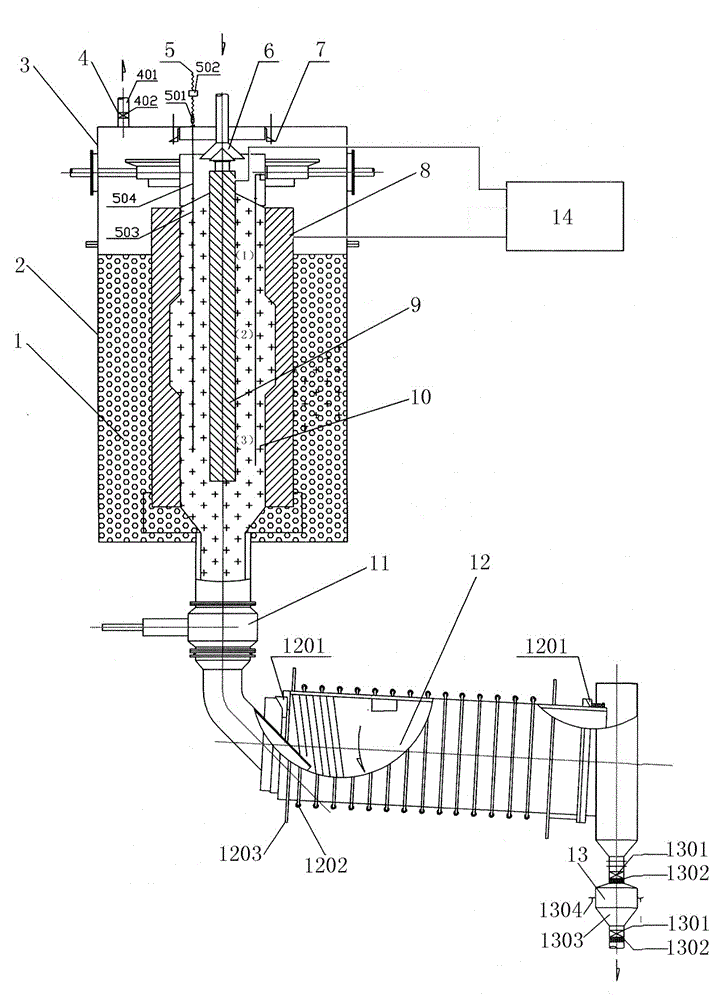

[0022] Such as figure 1 As shown, the high-efficiency sealed continuous graphitization furnace includes a furnace body 2, a sealing cover 3 is arranged above the furnace body 2, a feeding hopper 6 and a volatile matter discharge device 4 are arranged on the sealing cover 3, and a There is a sealing ring 7, and the volatile matter discharge device 4 includes a volatile matter discharge pipe 401 and a pneumatic valve 402, and the pneumatic valve 402 is arranged in the volatile matter discharge pipe 401; a graphite heating chamber is arranged inside the furnace body 2, and the graphite heating chamber is axially from the top It is divided into the preheating roasting zone (1), the slow heating zone (2) and the free heating zone (3). The cross-sectional area S2 of the slow heating zone is larger than the cross-sectional area S1 of the preheating roasting zone and the cross-sectional area of the free heating zone. Area S3. The center of the graphite heating chamber is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com