Movable arm variation-amplitude column crane counterweight automatic synchronization travel mechanism

A technology of tower cranes and mobile mechanisms, applied in cranes and other directions, can solve the problems of inconvenient installation and maintenance, large space occupation of the upper machine platform of the balance arm, and complicated structure, and achieve the effects of convenient installation and maintenance, simple structure, and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

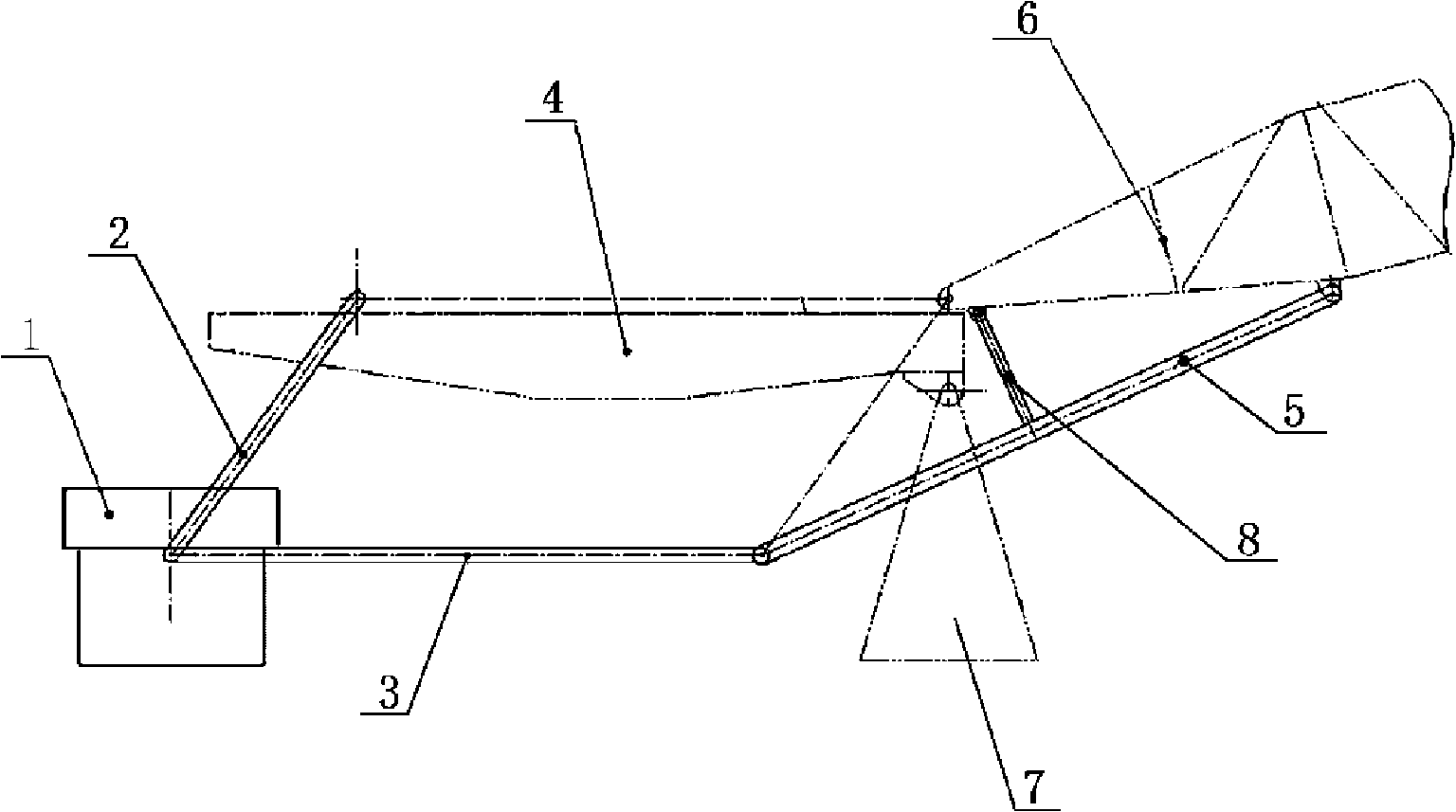

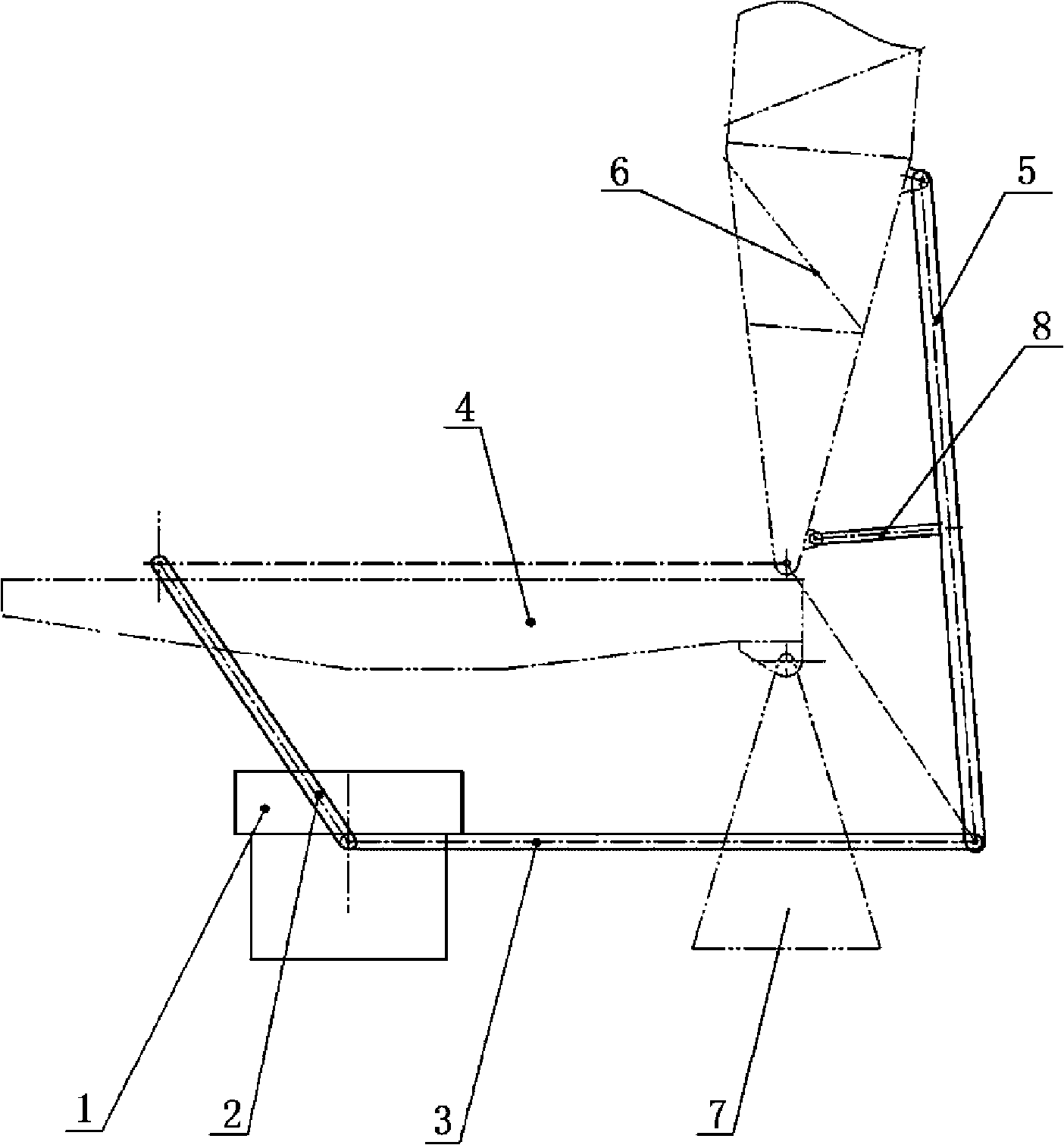

[0016] Examples see figure 1 shown, see figure 2 , referring to Fig. 3, the automatic synchronous movement mechanism of the counterweight of the boom tower crane is connected between the balance arm 4 and the boom 6, and the counterweight is fixed at the hinge point of the moving bar and the swing bar. The mechanism has the following main components:

[0017] Swing rod 2: one end is hinged on the balance arm 4, and the other end is hinged on the moving rod 3.

[0018] Moving rod 3: one end is hinged with the swing rod, and the other end is hinged with the jib transition connecting rod 5.

[0019] Transition connecting rod 5: it is actually a part of the jib. Connect the boom 6 and the moving rod 3. Through it, the mechanism moves with the swing of the jib 6 . The transition connecting rod 5 can also be a frame structure.

[0020] The swing bar 2, the moving bar 3 and the balance arm 4 form a parallel four-bar linkage mechanism. Wherein the balance arm 4 is a fixed rod,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com