Radiator fan

A technology for cooling fans and cylinders, applied in electromechanical devices, electrical components, liquid fuel engines, etc., can solve problems such as collisions, fan rotors easily detached from fans, and instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

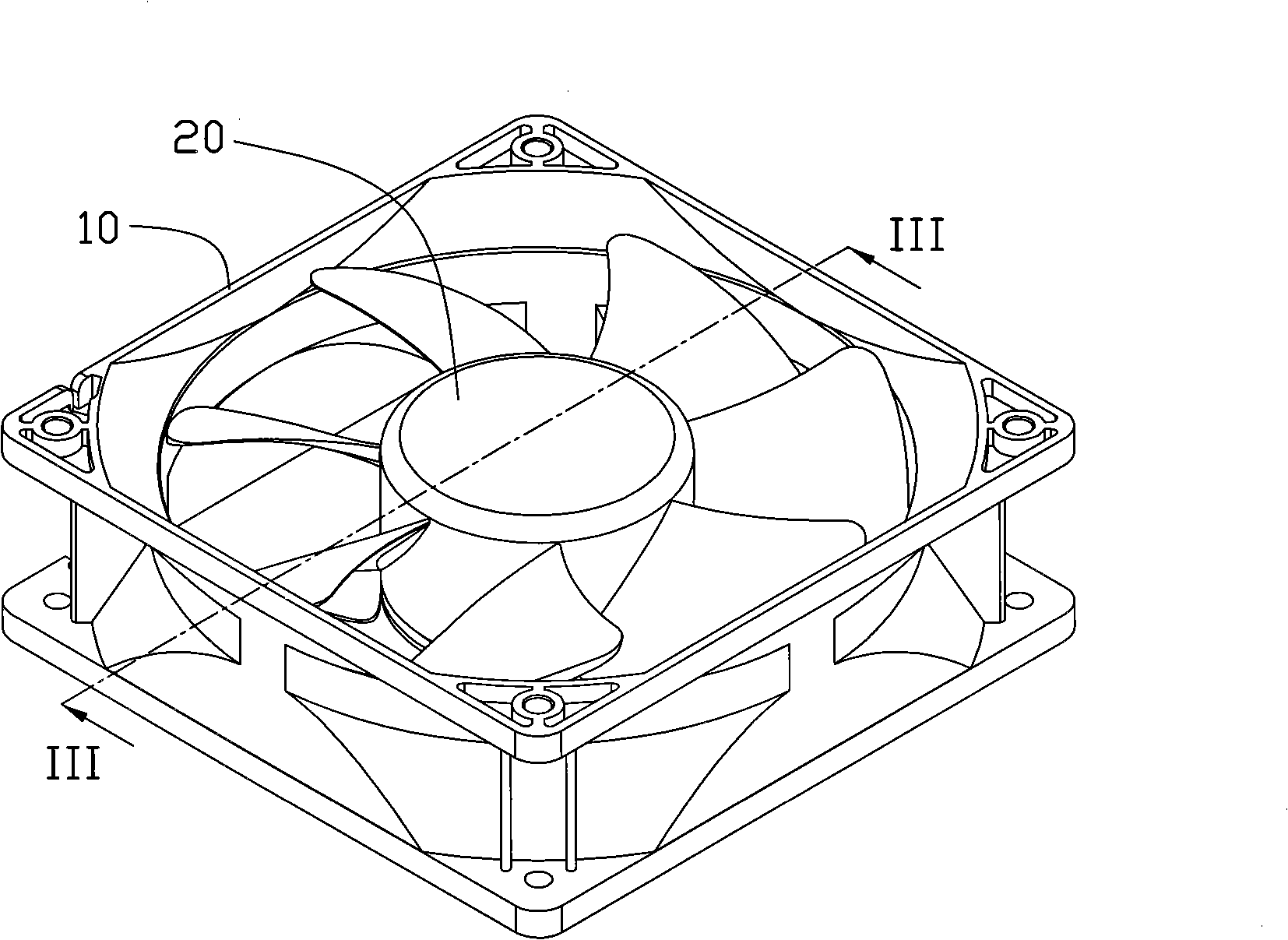

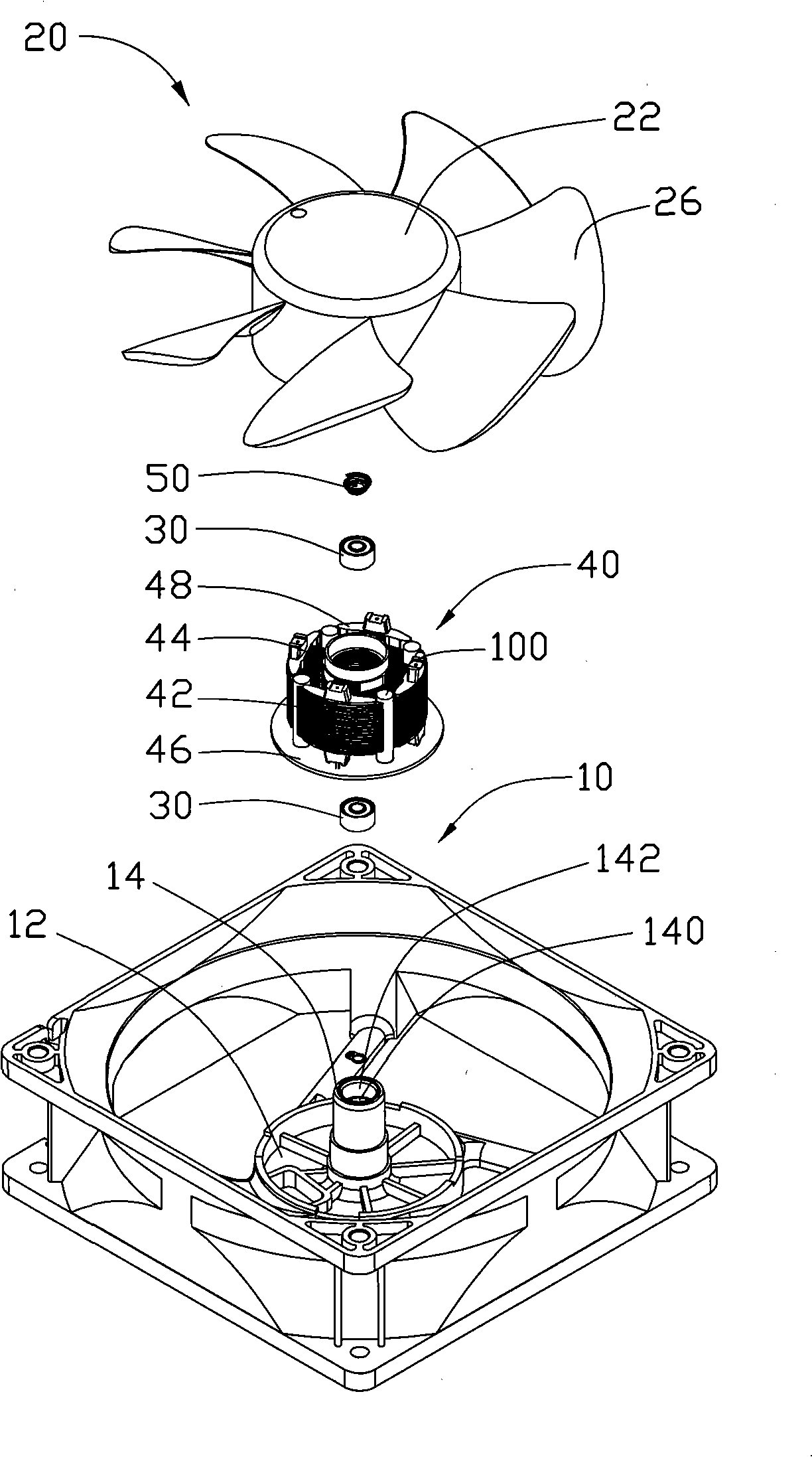

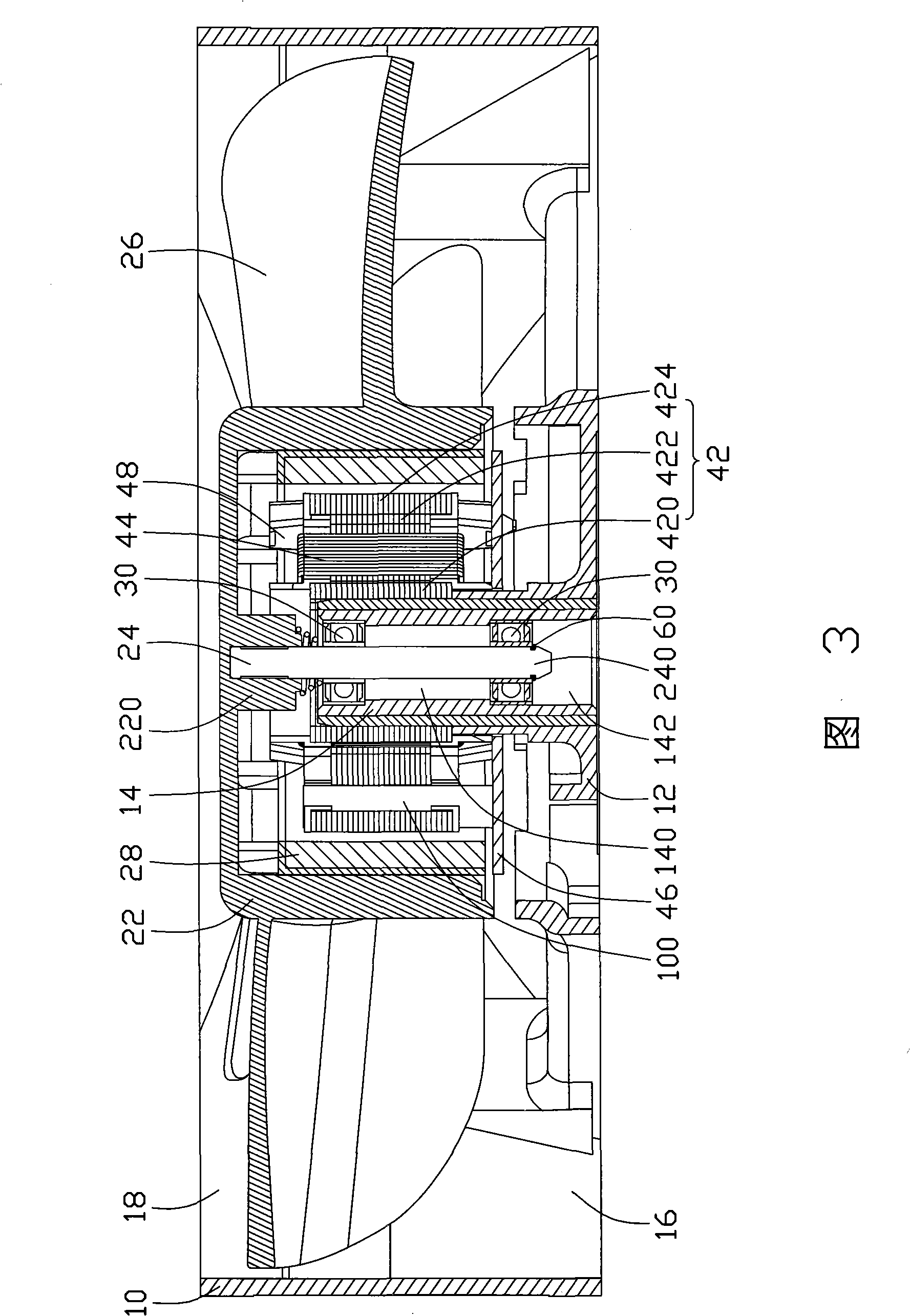

[0012] see figure 1 Referring to FIG. 3 , the cooling fan includes a fan frame 10 , a pair of bearings 30 , a rotor 20 and a stator 40 .

[0013] The fan frame 10 is square, and a through hole for accommodating the stator 40 and the rotor 20 is formed in the center, and an air inlet 18 and an air outlet 16 are respectively formed in the through hole corresponding to two sides (upper side and lower side) of the fan. The fan forms a pedestal 12 at the central position of the air outlet 16. The center of the pedestal 12 protrudes upwards to form a central column 14. A perforation 140 is formed in the center of the central column 14. The upper and lower ends of the central column 14 respectively form a The opening 142 is larger in diameter than the perforation 140 thereof.

[0014] The outer diameter of the pair of bearings 30 is substantially equivalent to the diameter of the opening 142 of the center column 14 , and are respectively accommodated in the openings 142 at the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com