Installation structure of sampling valve plate of lightning arrester resistance leakage current

A technology of leakage current and installation structure, applied in the field of installation structure of sampling valve plate, can solve the problems of complex installation process and high residual pressure, and achieve the effect of simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

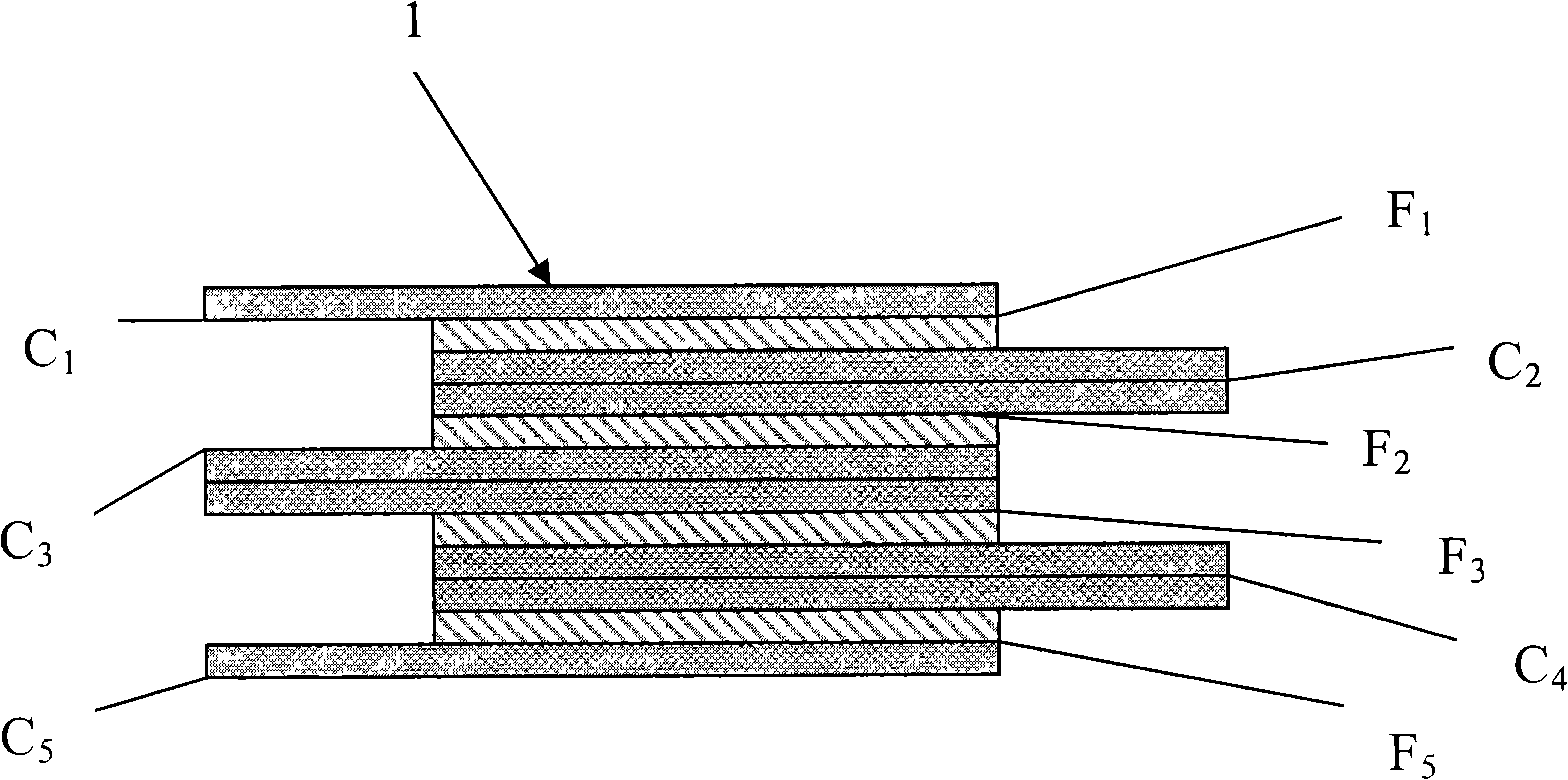

[0015] The installation structure of the sampling valve plate for the arrester resistive leakage current of the present invention includes a sampling valve plate and a mounting mold, wherein the sampling valve plate is composed of a plurality of valve layers tightly pressed together, and each valve layer is composed of two Composed of a copper sheet and a valve plate clamped between two copper sheets; a high-voltage input terminal and a grounding terminal are provided on the outer surface of the installation mold. The high-voltage input terminal and the grounding terminal can be M6 screws, and the sampling valve is installed on the The installation mold is insulated and cured into one body through epoxy resin and the installation mold.

[0016] In a preferred embodiment, see figure 1 , the installation structure of the sampling valve plate of the resistive leakage current of the arrester of the present invention includes a sampling valve plate 1 and an installation mold (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com