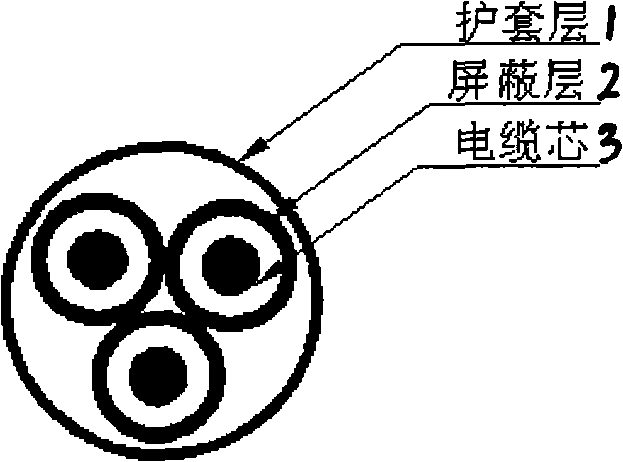

Measurement method for cable insulation leakage current

A technology of leakage current and measurement method, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., to achieve the effect of improving reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

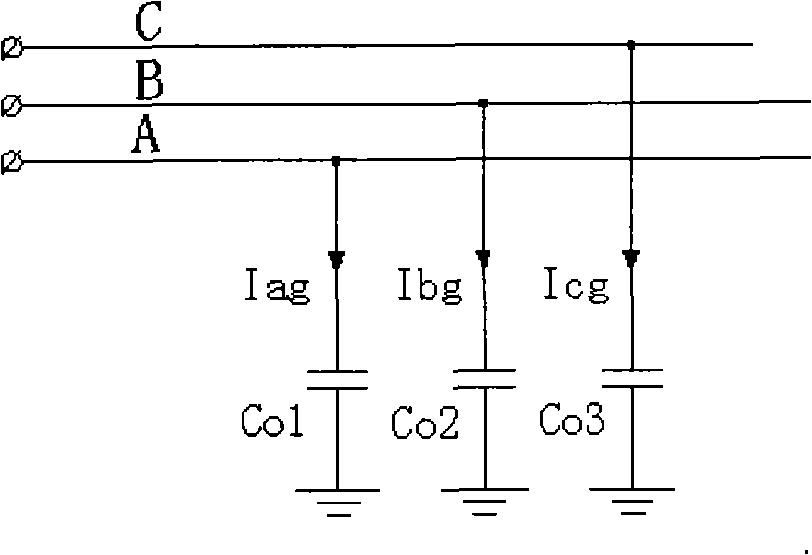

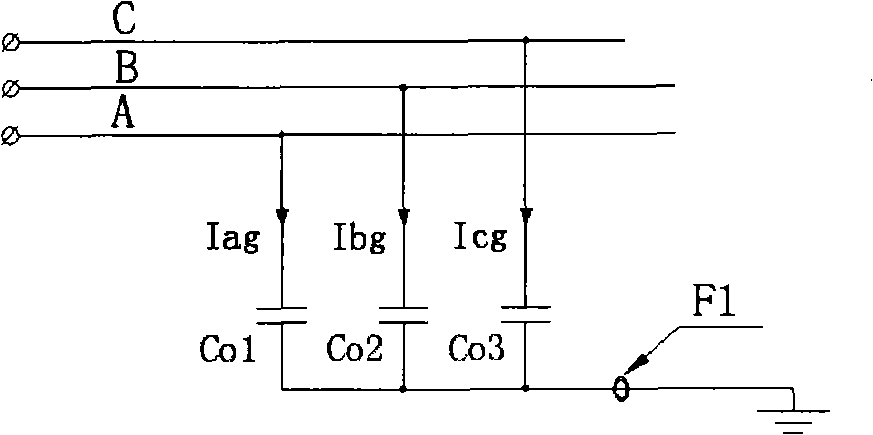

[0055] refer to Figure 5 , the present invention is implemented like this:

[0056] The present invention adopts the mirror image current source testing technology, and taking A-phase current measurement as an example, in the new test method, the sensor for testing the A-phase current is divided into two parts, namely CT1 and CT1', and CT1 and itself are used in the production in advance The current flow direction of the mirror image CT1' is in a symmetrical state; that is

[0057] Ict1=Iag+Iaf

[0058] Ict1'=-(Iaf+(2Iag))

[0059] Io=Ict1+Ict1'=-Iag

[0060] As mentioned above, through the mirror current source technology, the required current component -Iag (A relative ground leakage current component) is measured, and the negative sign is meaningless to the measurement result; the same principle is used to measure Ibg (B relative ground leakage current component) and Icg (C relative to the leakage current comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com