Porous cast iron platform with self-bringing clamping apparatus

A cast iron platform with its own technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of cumbersome, inconvenient press-fitting and disassembly, and achieve the effect of overcoming cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

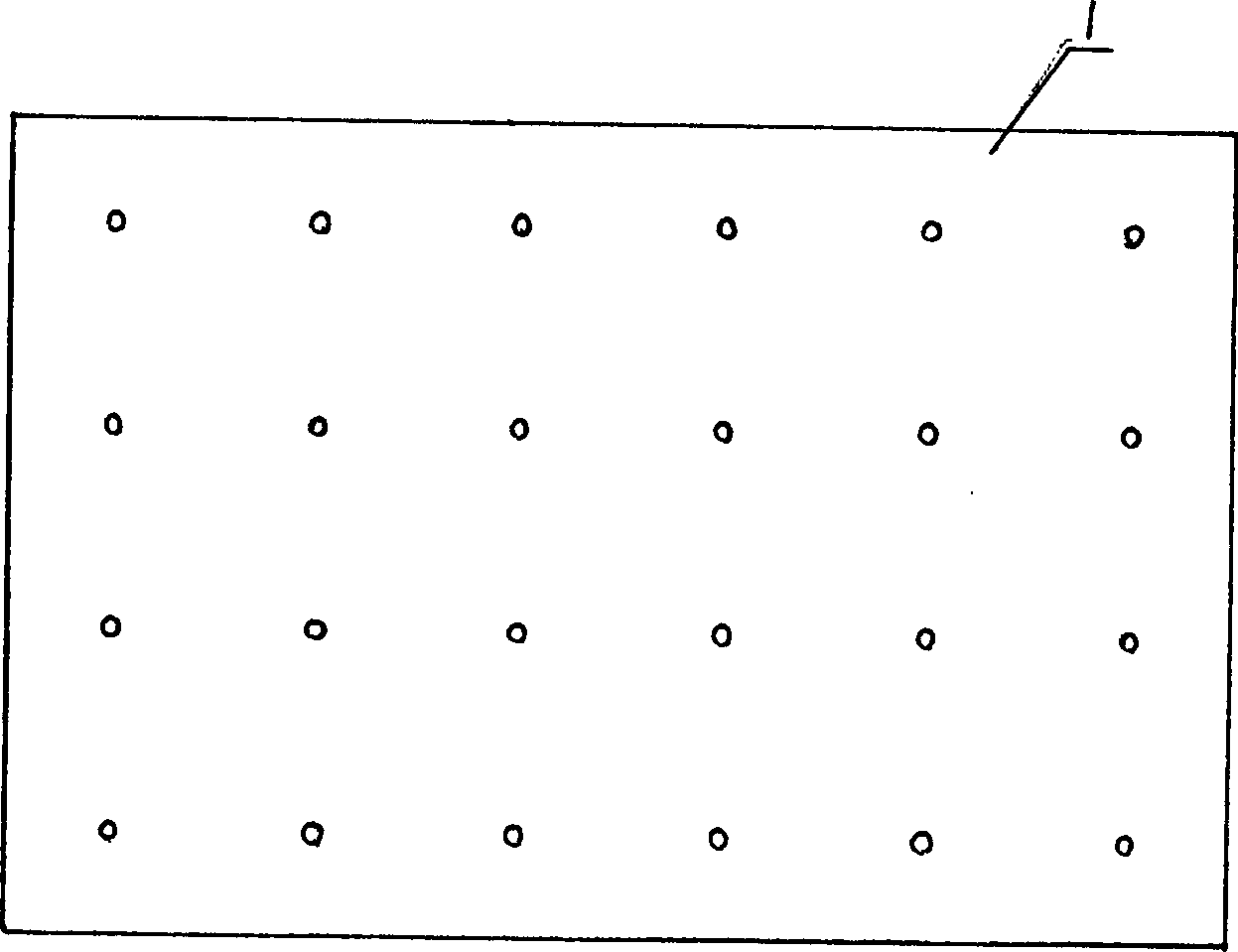

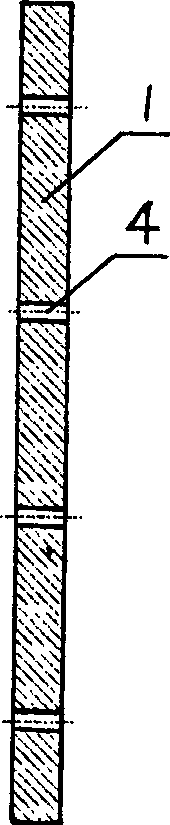

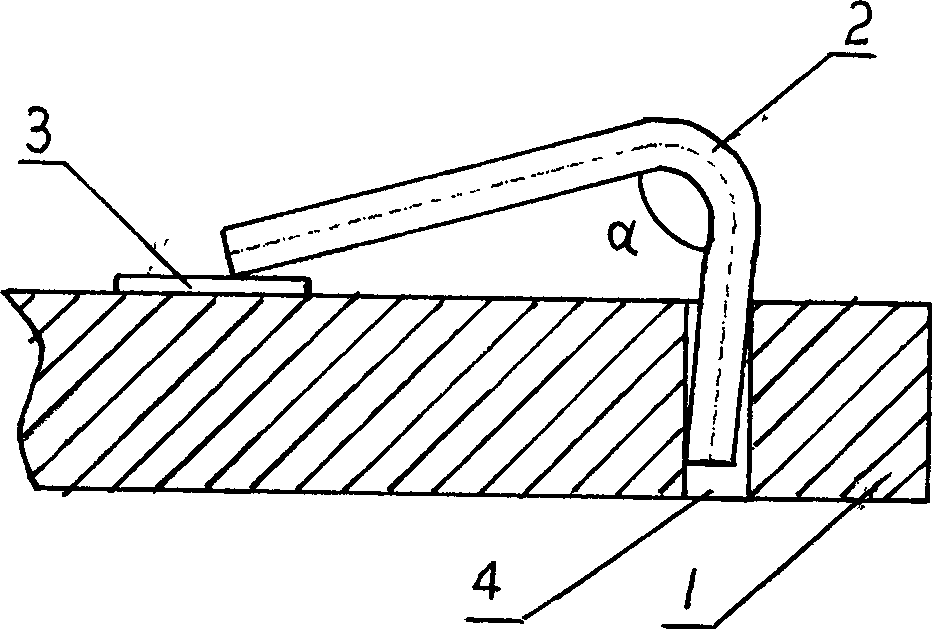

[0013] as attached figure 1 , 2 , 3, the present invention includes a cast iron platform 1, a fixing hole 4 arranged on the cast iron platform 1, and an L-shaped fixture 2 inserted into the fixing hole 4 at one end. The angle α between the two clamping strips of the L-shaped fixture 2 is 55°≤α≤75°. The L-shaped fixture 2 is made of metal material. The platform of the present invention is formed by casting, and an appropriate number of fixing holes 4 are arranged on it, and when the workpiece 3 is pressed, press image 3 Put the workpiece 3 in a suitable position, insert one end of the fixture 2 into the fixing hole 4 of the cast iron platform 1, and put the other end on the upper surface of the workpiece 3, the angle between the two clips of the L-shaped fixture 2 is α It can be 55°, 60° or 75°, and the top of the fixture 2 is hit with a hammer, and the fixture 2 produces elastic deformation, so that the cast iron platform 1, the workpiece 3, and the fixture 2 can complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com