Integrated control circuit of biomass cooking range

An integrated control circuit and biomass technology, which is applied in the direction of household stoves/stoves, lighting and heating equipment, solid heating fuel, etc., can solve the problems of cumbersome operation, high failure rate, and high energy consumption, and achieve cumbersome operation and convenient use , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

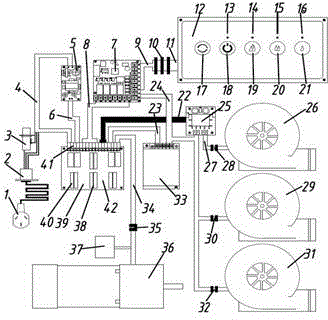

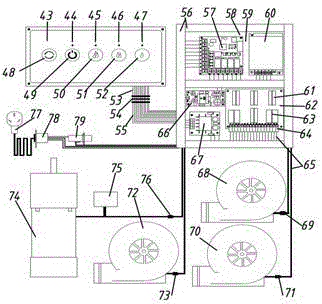

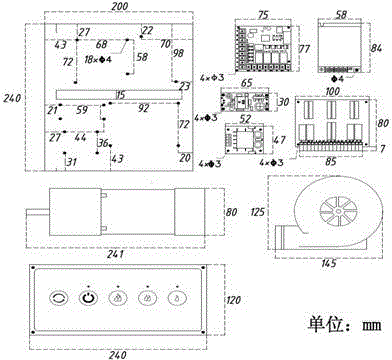

[0016] Such as figure 1 As shown, a biomass stove integrated control circuit, switch panel (12), consists of emergency stop button (17), start / stop button (18), high fire button (19), medium fire button (20), low fire button (21), power indicator light (13), high fire indicator light (14), medium fire indicator light (15) and small fire indicator light (16). The lead wire (11) of the panel switch is connected with the Dupont wire (9) through the pin (10), and the Dupont wire (9) is connected with the programmable controller (7). The programmable controller (7) is connected to the relay peripheral circuit board (39) through the 8# control line (8), and the relay peripheral circuit board (39) is connected to the voltage regulating module (25) through the 22# control line (22). The relay peripheral circuit board (39) is composed of a relay (40), a relay fixing hook (38), a plug-in terminal block (41) and a relay PCB bottom plate (42). The three-plug power cord (1), the character ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com