Precise testing device of safety valve of cylindrical lithium-ion battery

A lithium-ion battery and testing device technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, can solve the problems of low test accuracy, low work efficiency, cumbersome operation, etc., and achieve Reduce manual operations, reduce consumables, and detect stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

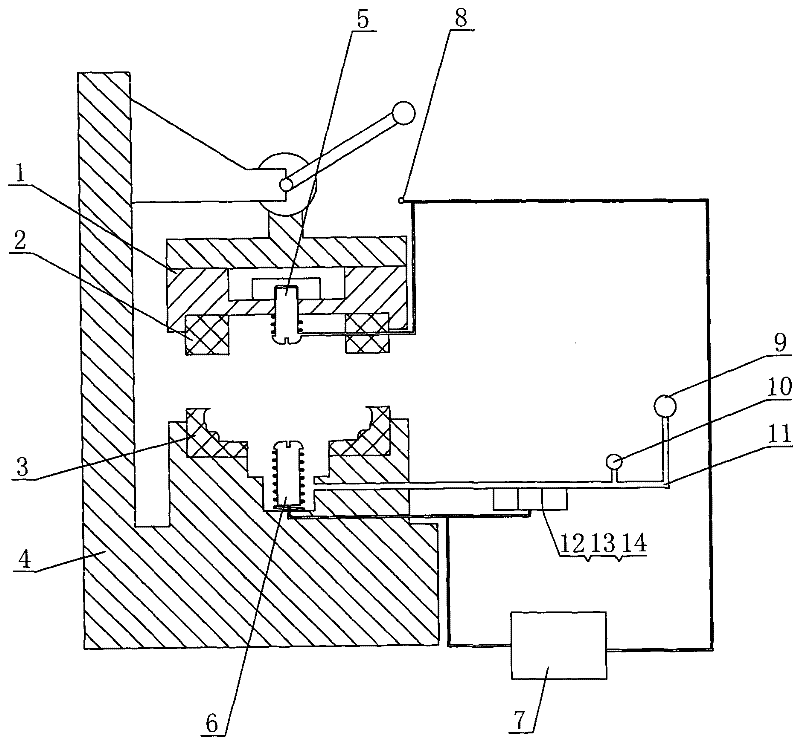

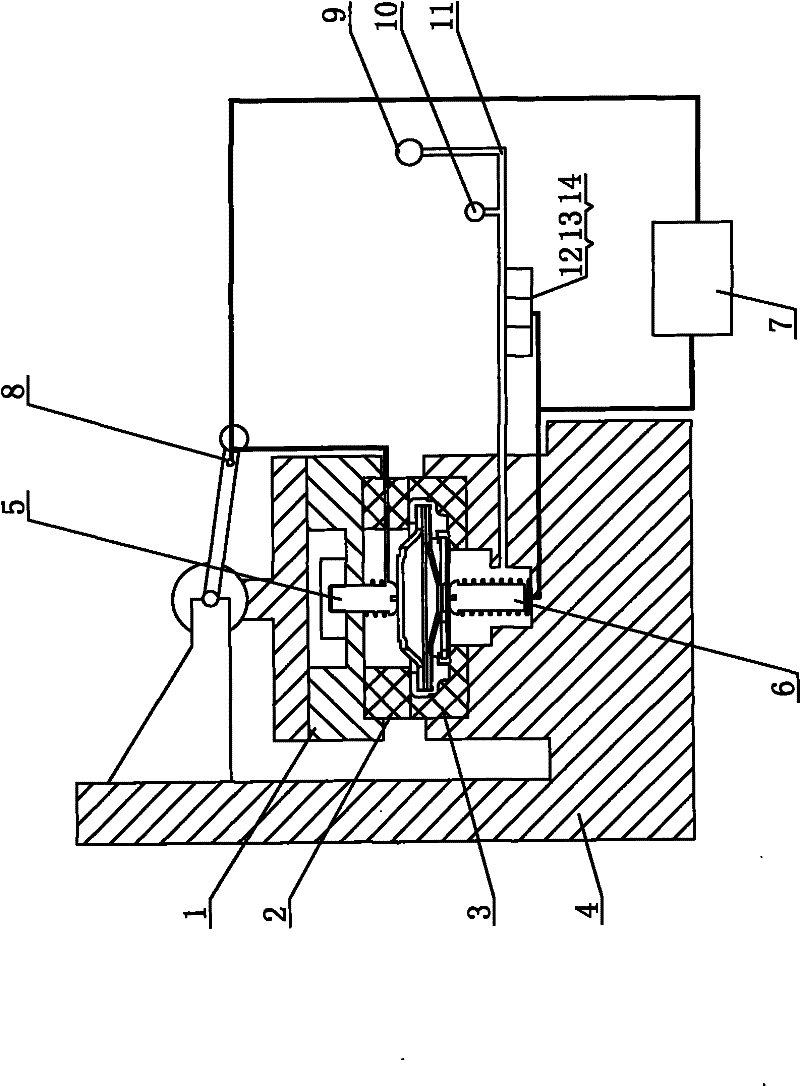

[0026] figure 1 As shown, the cylindrical lithium-ion battery safety valve precision testing device mainly includes a pressure seat 1, a base 4, a control system 7, a stabilized air source 9, and an air intake pipe 11. The hollow cavity openings of the pressure seat 1 and the base 4 are respectively provided Gaskets 2, 3, and pressure seat 1 are installed on the side frame of base 4. Pull down or lift the handle along the side frame to compress or separate pressure seat 1 and base 4. The hollow cavities of pressure seat 1 and base 4 are respectively There are elastic contacts 5 and 6, and the two elastic contacts 5 and 6 are respectively connected with the control system 7, and the press seat 1 and the base 4 are pressed against the safety valve to be tested. When the safety valve to be tested is closed, the two elastic contacts 5 and 6 respectively touch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com