Patents

Literature

31results about How to "Overcome cumbersome operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Momordica grosvenori extractive with at least 40 percent grosvenor momordica glycoside and preparation method thereof

InactiveCN101200753AReduce the amount of feedShorten the production cycleFermentationFood preparationSocial benefitsEnzymatic hydrolysis

The invention provides a milk white fructus momordicae extract, fructus momordicae glycoside V and fructus momordicae glycoside of which are respectively larger than or equal to 40 percent and 98 percent. The invention also discloses a preparation method of the extract. Using fresh fructus momordicae as the raw material, the invention is obtained through the water extraction, the concentration, the enzymatic hydrolysis, the macroporous adsorption resin refining, the ion exchange resin decoloration, the concentration and the spray drying. The invention is characterized in that the process parameters of the steps which are suitable for the industrial production are found, the yield and the quality of the fructus momordicae extraction are all obviously improved, and obvious economic benefits and social benefits are obtained.

Owner:GUILIN HUITONG BIOTECH

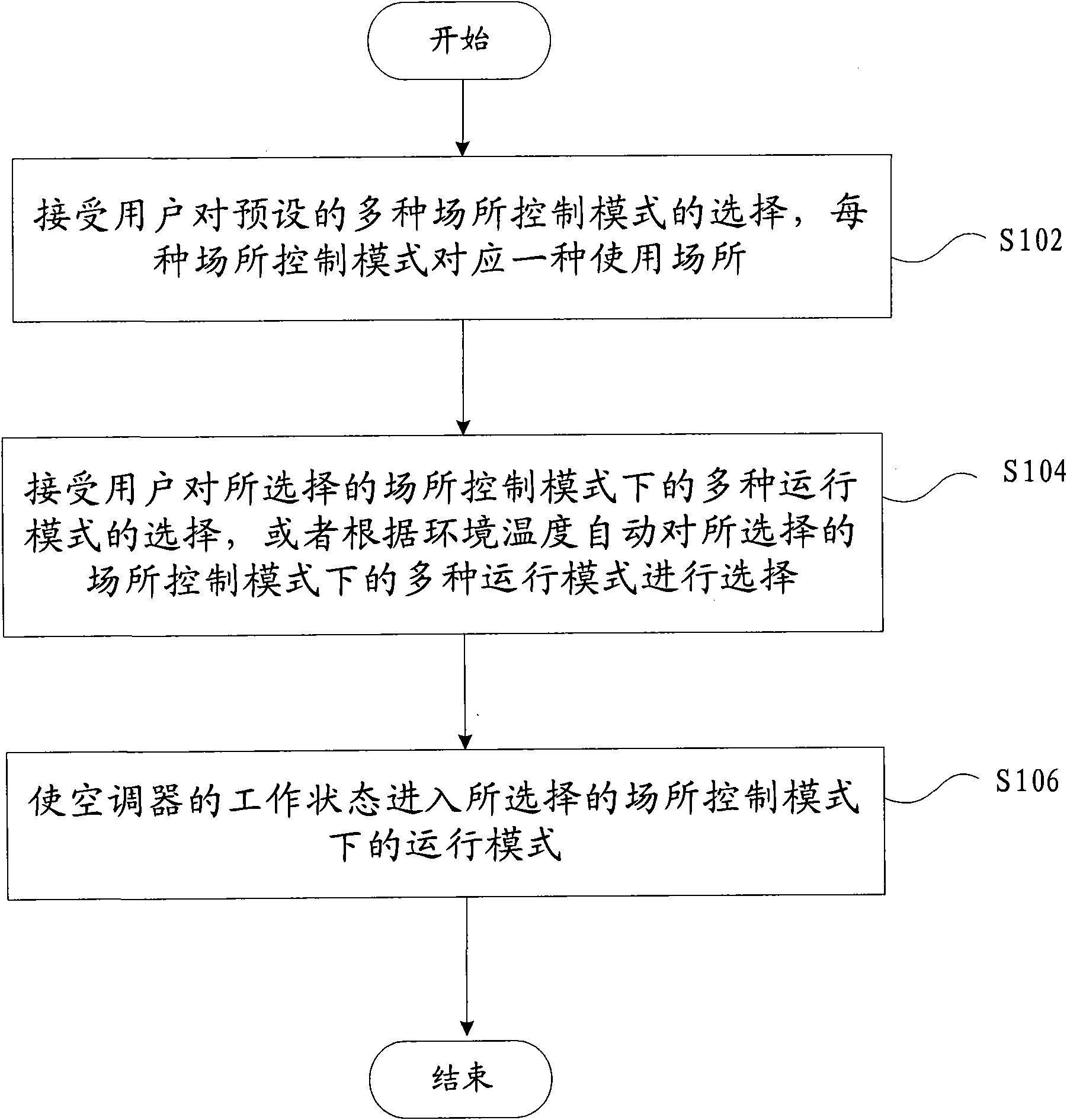

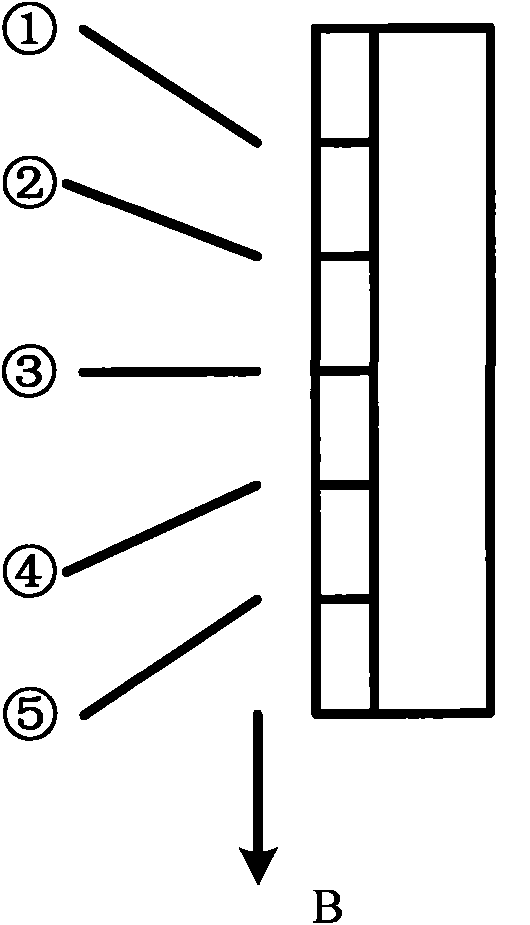

Control method for air conditioner

InactiveCN101818933AReduce stepsOvercome cumbersome operationsSpace heating and ventilation safety systemsLighting and heating apparatusControl modeEnvironmental temperature

The invention provides a control method for an air conditioner, which comprises the following steps: receiving selection of a user on preset multiple place control modes, wherein each place control mode corresponds to a using place; receiving selection of the user on multiple operating modes under the selected place control mode, or automatically selecting multiple operating modes under the selected place control mode according to the environmental temperature; and making the working state of the air conditioner enter the operating mode under the selected place control mode. The control method solves the problem of fussy operation because the air conditioner in the prior art needs to be provided with more parameters, reduces the operation of the user, and can enter the air conditioner working state expected by the user and adapted with the place through simple selection.

Owner:GREE ELECTRIC APPLIANCES INC

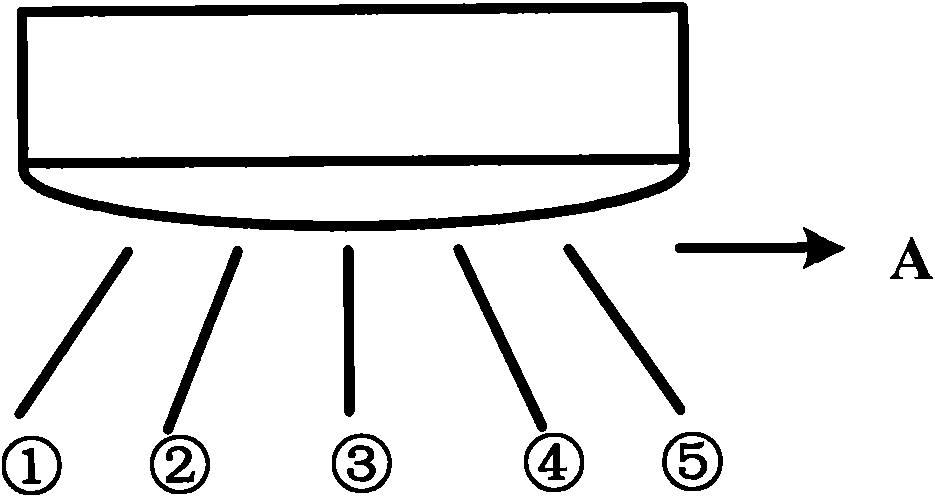

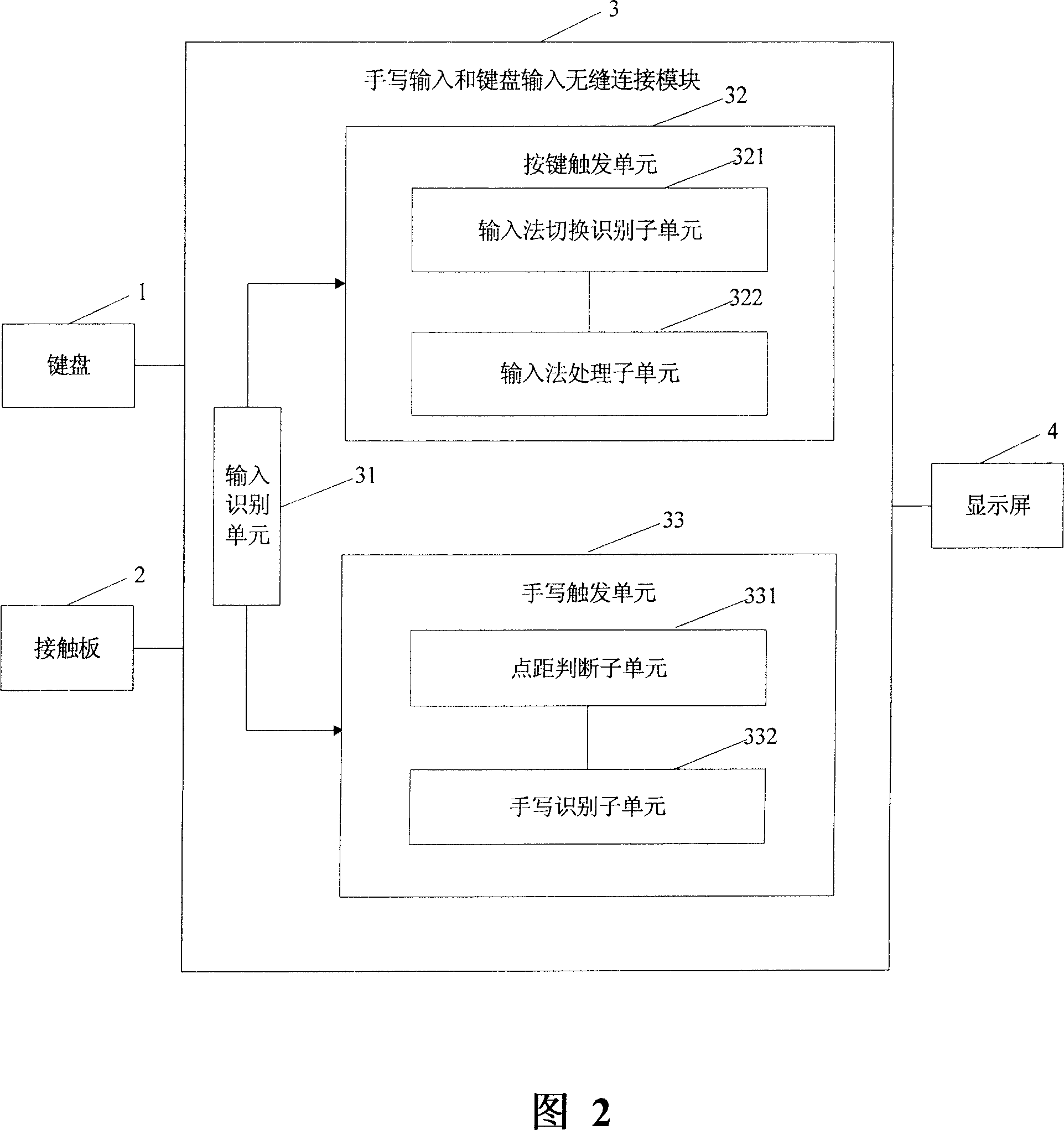

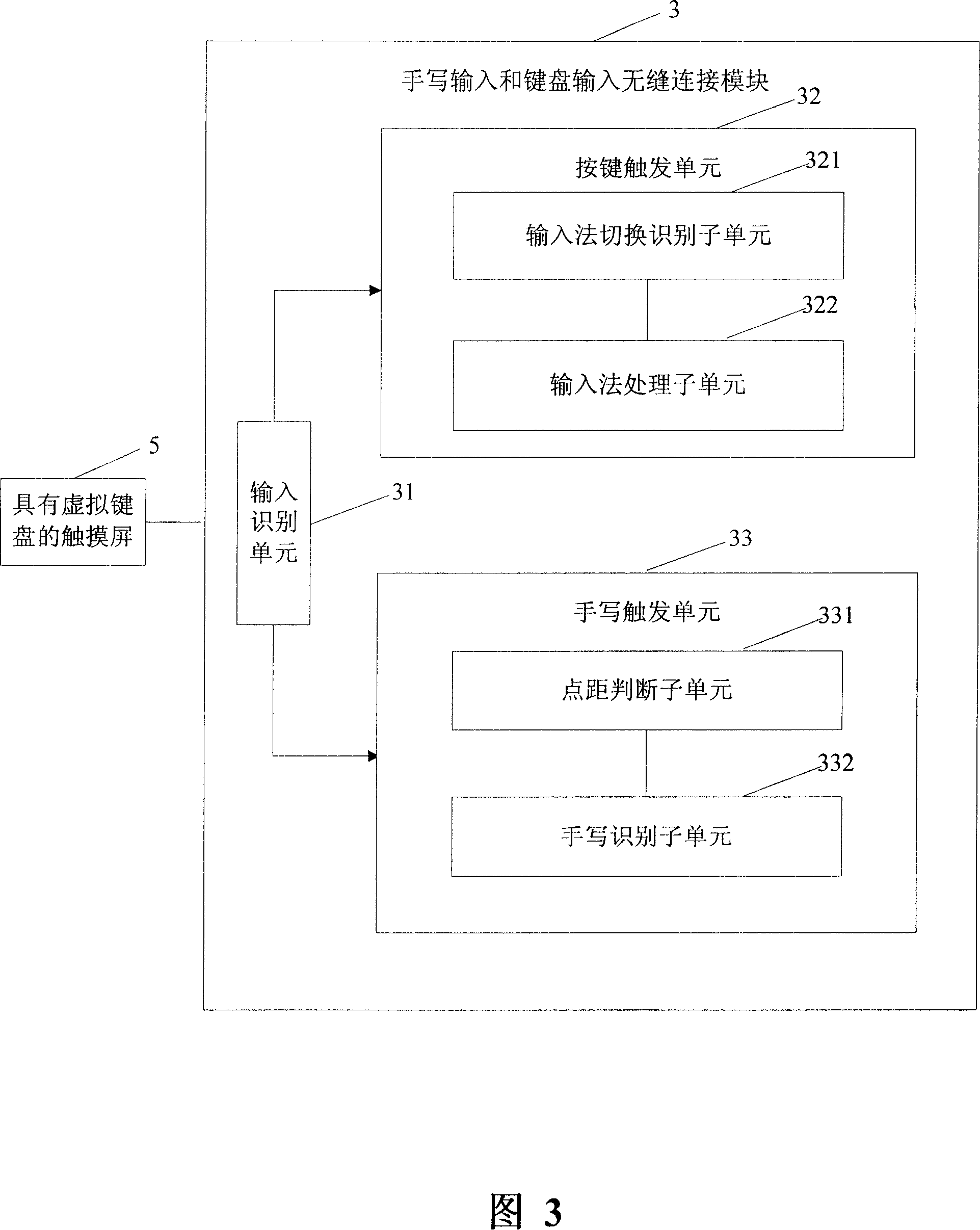

Device and method supporting hand-written input and keyboard input

InactiveCN101118472AOvercome cumbersome operationsEasy to operateInput/output processes for data processingHandwritingComputer engineering

The present invention discloses a device which supports the handwriting input and the keyboard input and a method of the handwriting input and the keyboard input. When the input signal is a handwriting input signal, the user can directly enter into a handwriting input recognizing and processing course; when the input signal is a keyboard input signal, the user can directly enter into a keyboard input processing course. The present invention comprises a keyboard, a contacting board, and a display screen, and is characterized in that the present invention also comprises a handwriting input and keyboard input seamless linking module which is respectively connected with the keyboard, the contacting board and the display screen; the handwriting input and keyboard input seamless linking module is used for identifying whether the input signal is the handwriting input from the contacting board or the input from the keyboard, the handwriting input recognizing and processing is performed for the handwriting input signal from the contacting board, and the keyboard input processing is performed for the input signal from the keyboard. The device and the method provided by the present invention can realize the seamless switching of the handwriting input and the keyboard input.

Owner:LENOVO MOBILE COMM TECH

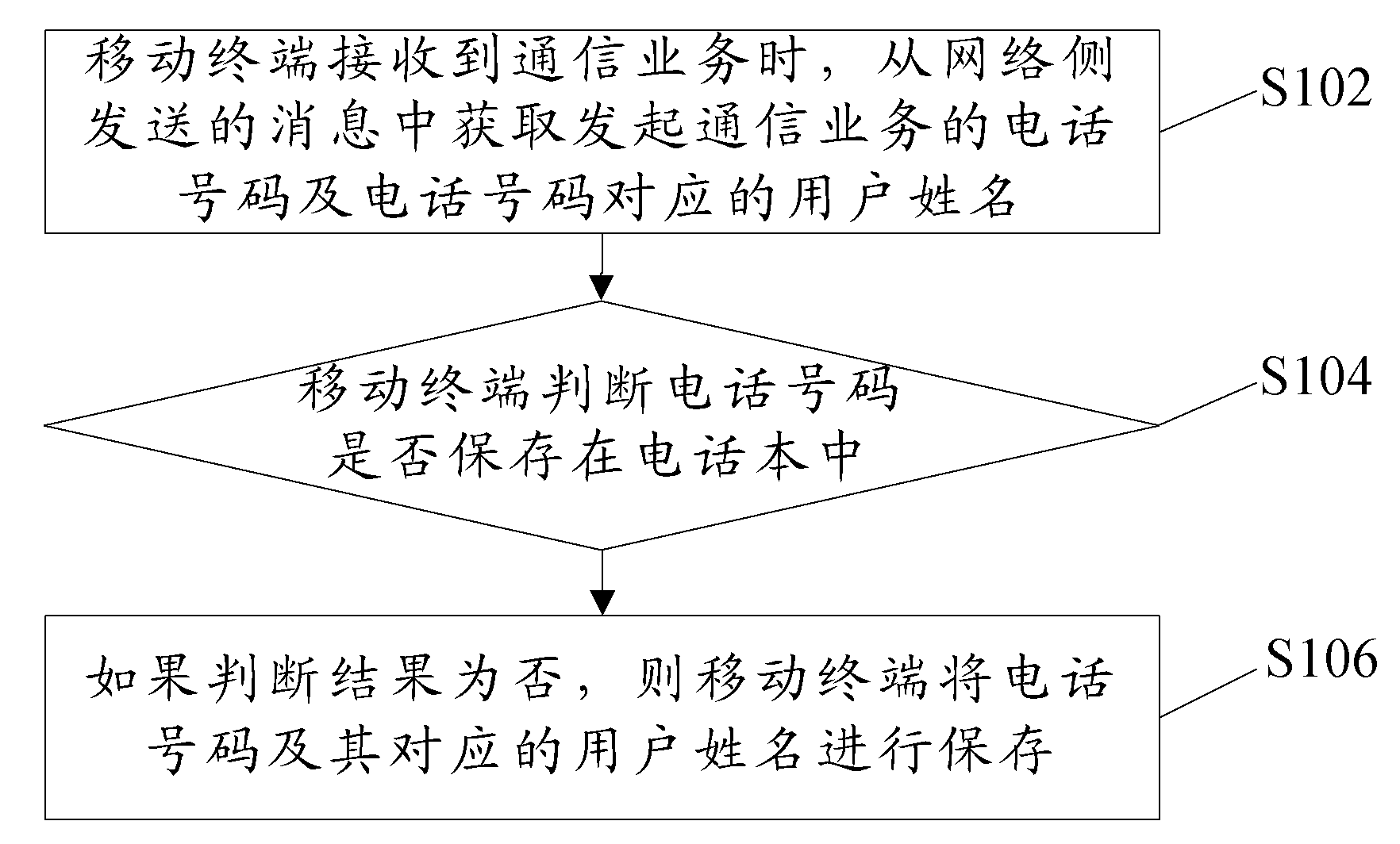

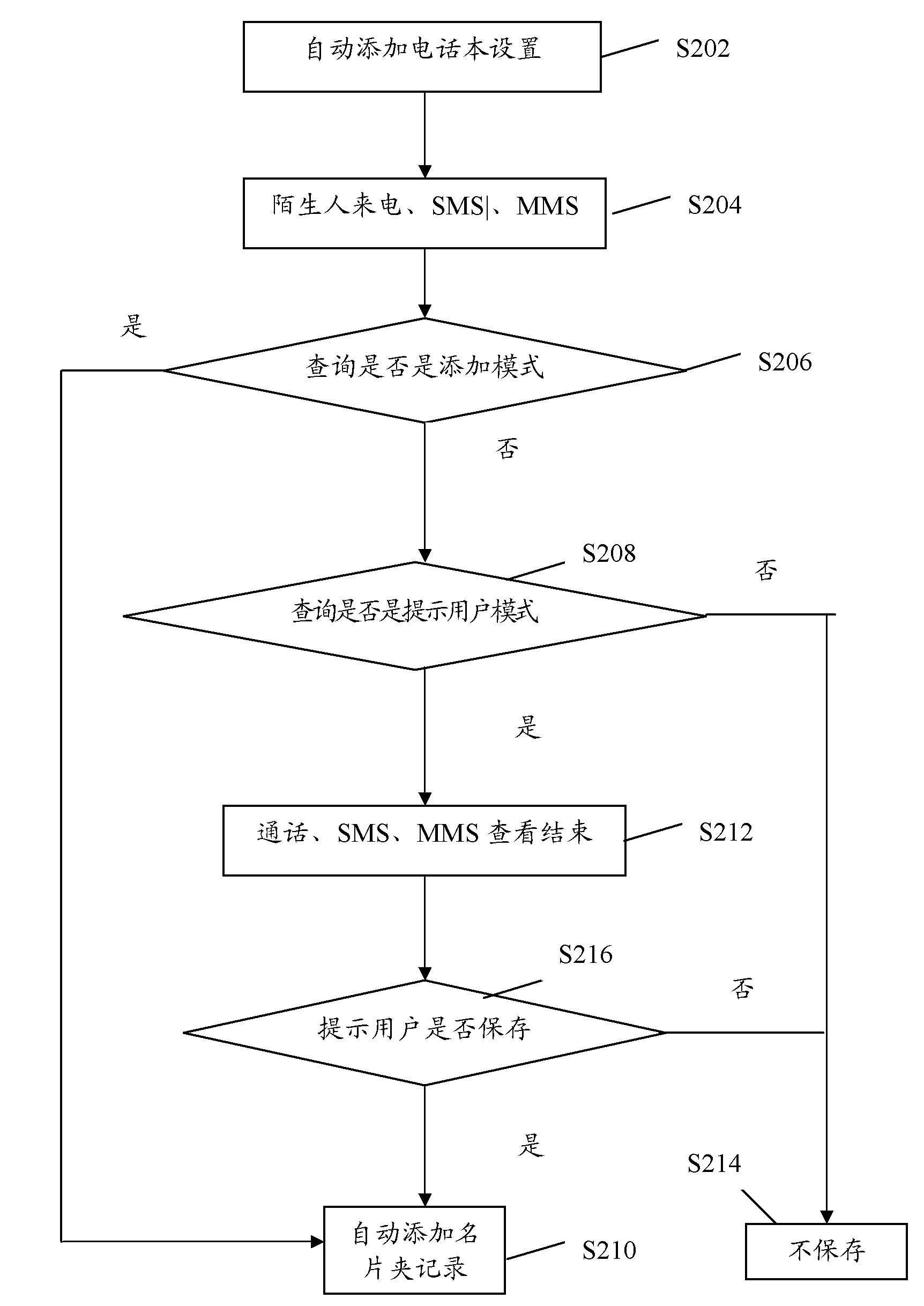

Telephone number storage method and mobile terminal

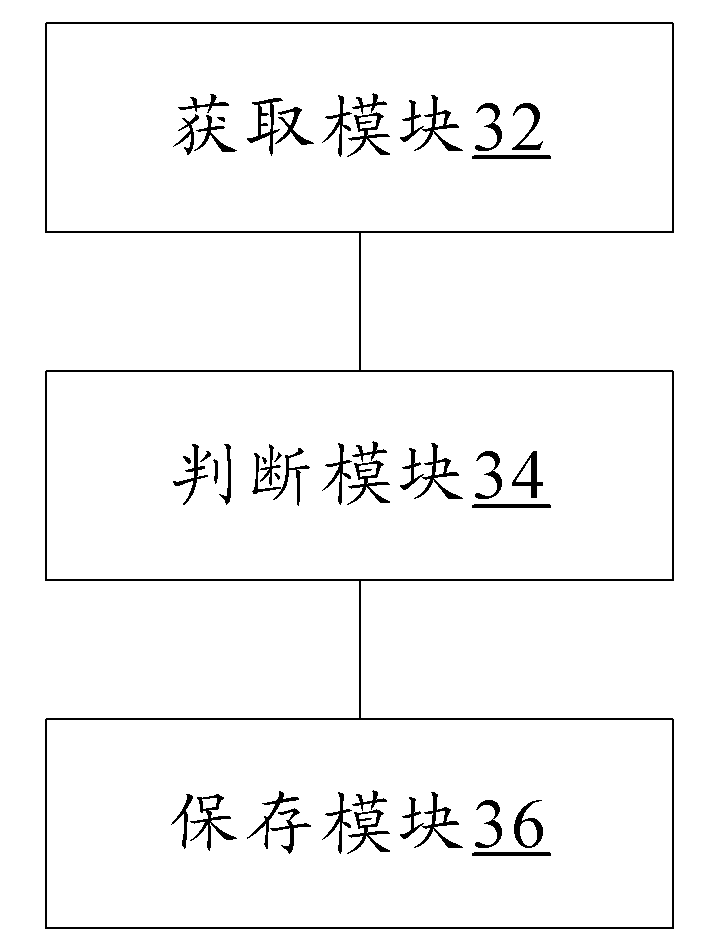

InactiveCN101984683AOvercome cumbersome operationsImprove user experienceSubstation equipmentMessaging/mailboxes/announcementsTelecommunicationsUser experience design

The invention discloses a telephone number storage method and a mobile terminal. The method comprises the following steps: after receiving a communication service, the mobile terminal acquires a telephone number initiating the communication service and a user name corresponding to the telephone number from a message sent by a network side; the mobile terminal judges whether the telephone number is stored in a telephone book; and if the telephone number is not stored in the telephone book, the mobile terminal stores the telephone number and the corresponding user name. The invention enhances the user experience.

Owner:ZTE CORP

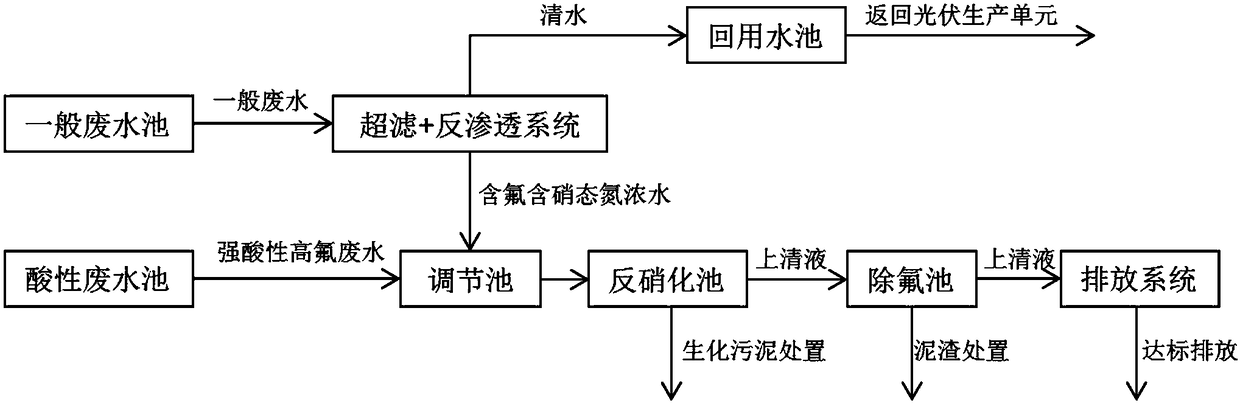

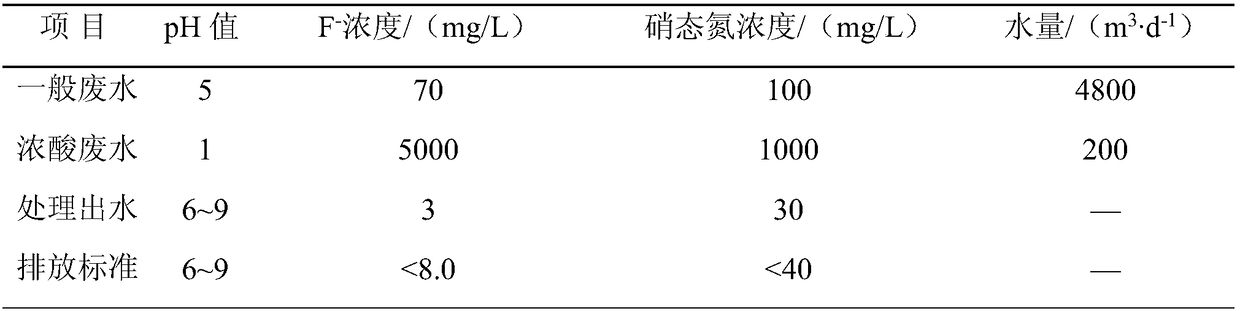

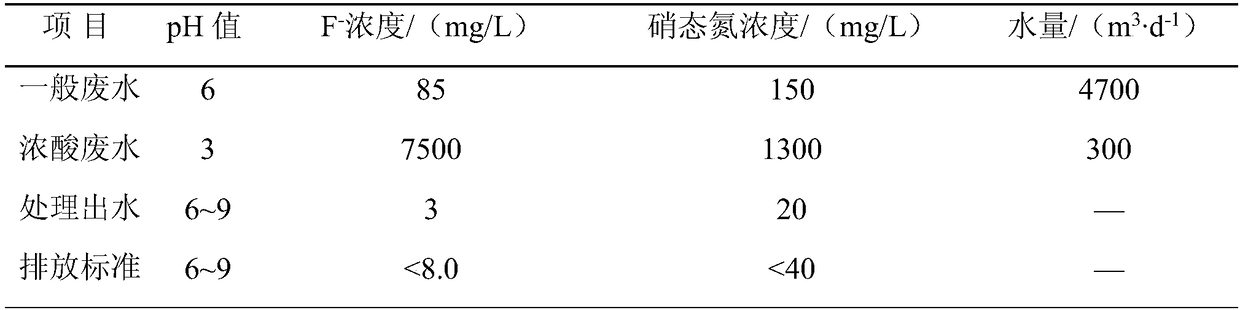

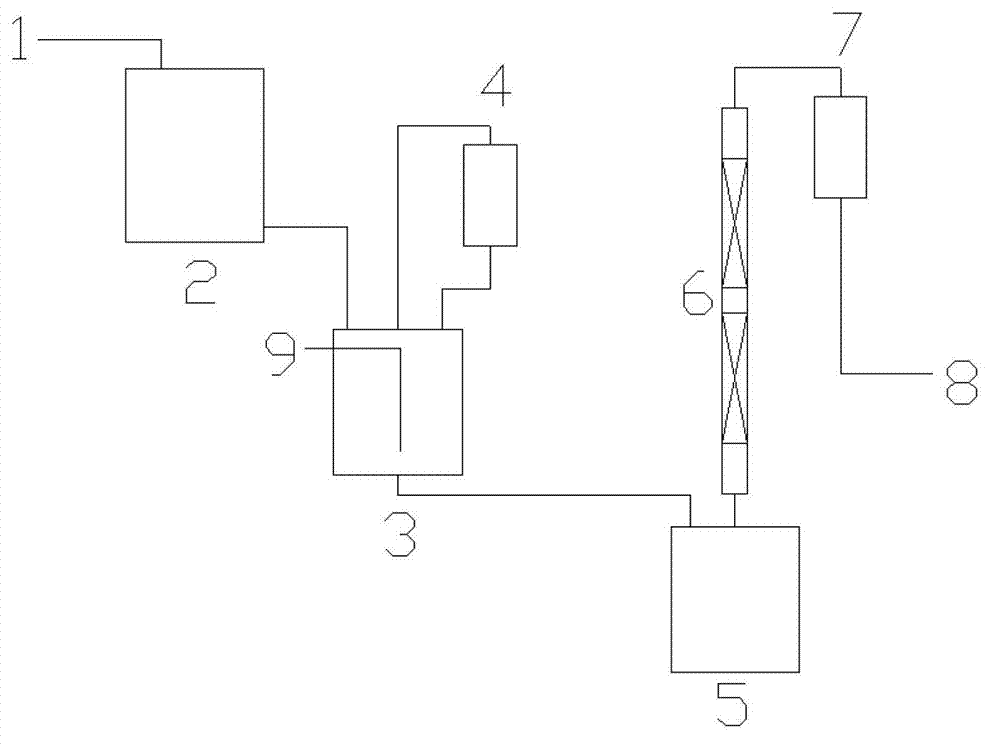

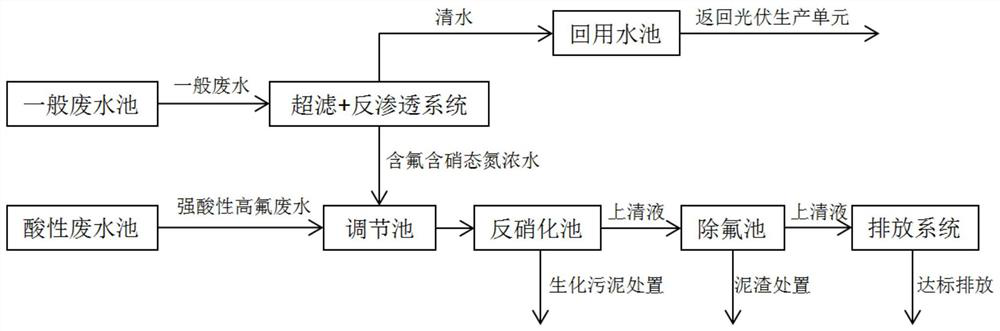

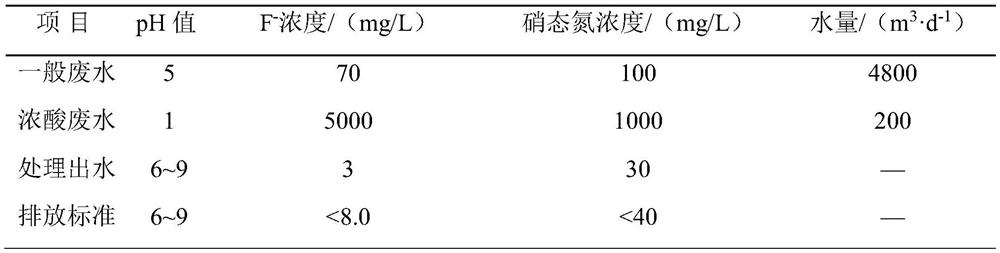

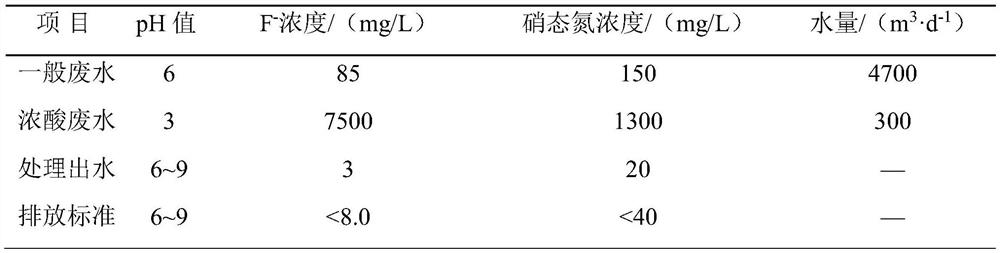

Treatment system and treatment method of fluorine-containing and nitrate nitrogen-containing industrial waste water

ActiveCN108249707AReduce volumeSmall footprintWater contaminantsTreatment with anaerobic digestion processesIndustrial waste waterUltrafiltration

The invention discloses a treatment system and treatment method of fluorine-containing and nitrate nitrogen-containing industrial waste water, which belongs to the technical field of waste water treatment. The treatment system and method are used for firstly separating ordinary waste water into fluorine-containing and nitrate nitrogen-containing concentrated water and clean water by virtue of a hyperfiltration and reverse osmosis system, then mixing the fluorine-containing and nitrate nitrogen-containing concentrated water and strong-acidic waste water, guide the mixed water into a denitrification pool, and discharge the water up to standard after the fluorine removal by virtue of denitrification nitrogen removal and a chemical precipitation method. By adopting the method disclosed by theinvention, the biochemical and chemical precipitated waste water amount can be effectively reduced, the floor occupation area of a waste water pool can be reduced, and the fixed investment cost is decreased; and in addition, an alkali precipitation unit is arranged behind a biochemical reaction unit, so that the acid consumption and alkali increasing effect of the denitrification reaction can be sufficiently utilized, the cost of a great amount of alkali for removing fluorine and a great amount of acid for the denitrificaiton process in the traditional process is decreased, and the treatment system and the treatment method are suitable for the industrialized application.

Owner:NANJING UNIV +1

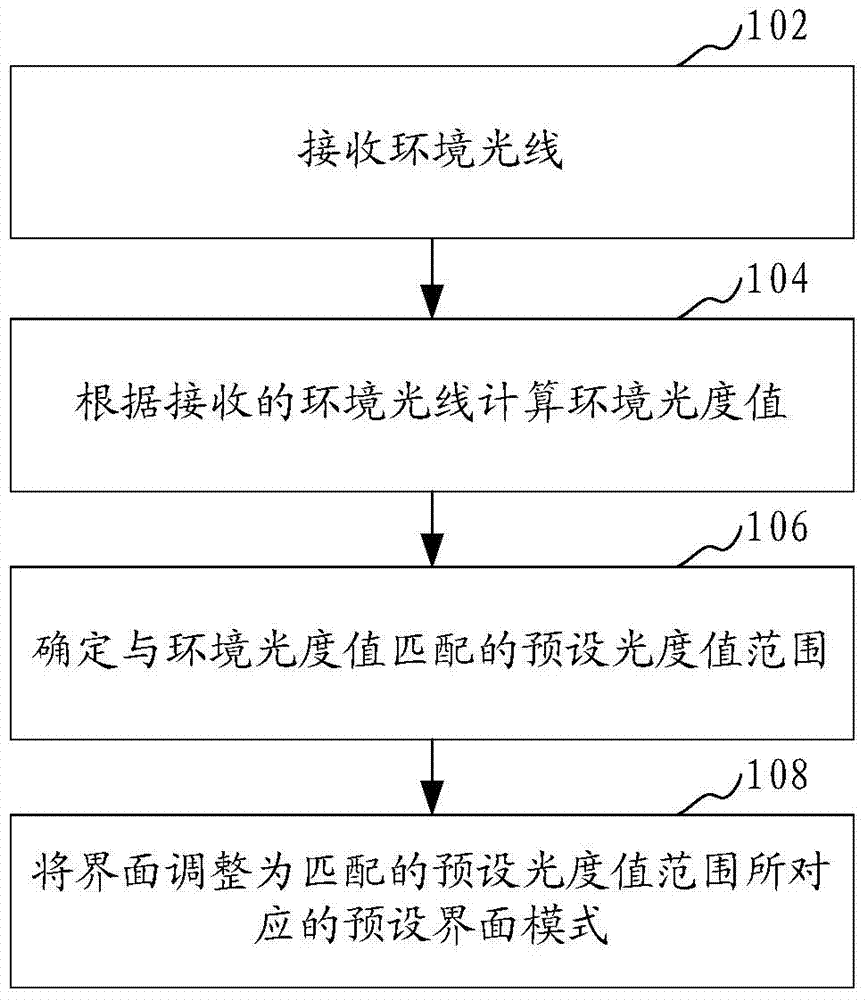

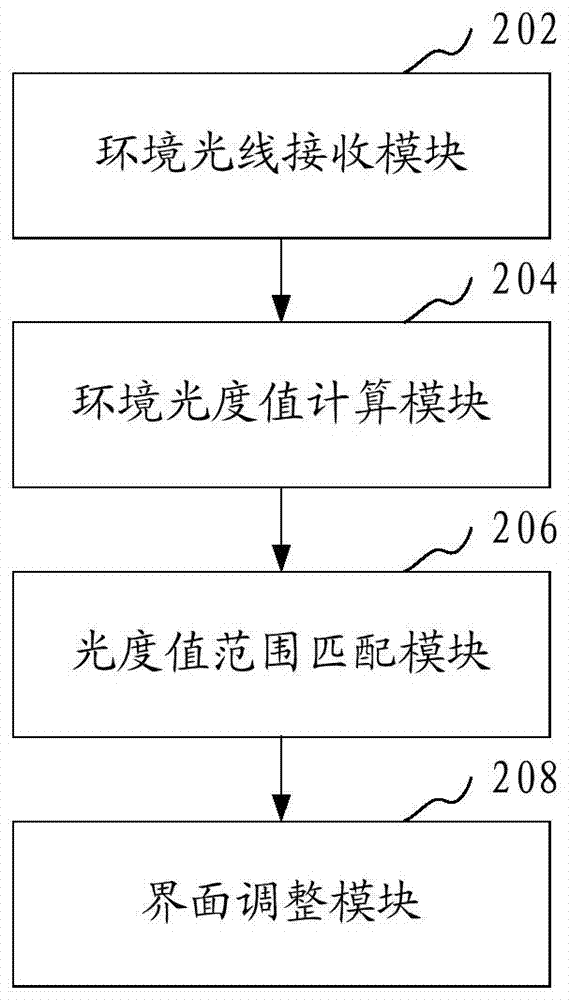

Interface display control method and device

InactiveCN104777973AOvercome cumbersome operationsOvercome the cumbersome operation of manual adjustment interfaceInput/output for user-computer interactionGraph readingComputer hardwareLuminosity

The invention provides an interface display control method, which comprises the following steps: receiving ambient light; according to the received ambient light, calculating an ambient luminosity value; determining a preset luminosity value range matched with the ambient luminosity value; and regulating an interface into a preset interface mode corresponding to the matched preset luminosity value range. The interface display control method receives the ambient light so as to calculate the ambient luminosity value, and determines the preset luminosity value range matched with the ambient luminosity value so as to regulate the interface into the interface mode corresponding to the matched preset luminosity value range, the interface can be regulated automatically according to the ambient light without a manual operation, and the problem of complexity in the operation of the manual regulation of the interface is overcome. The invention also provides an interface display control device.

Owner:TENCENT TECH (SHENZHEN) CO LTD

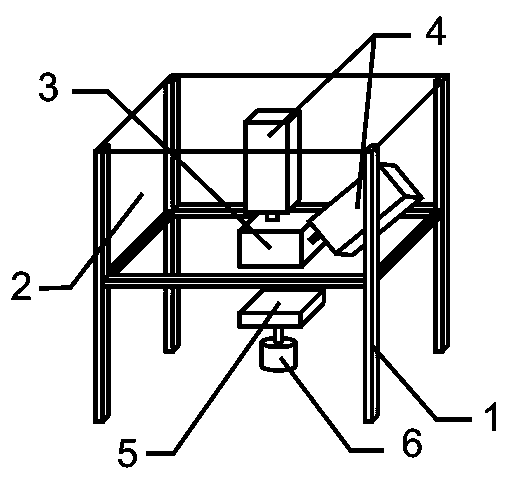

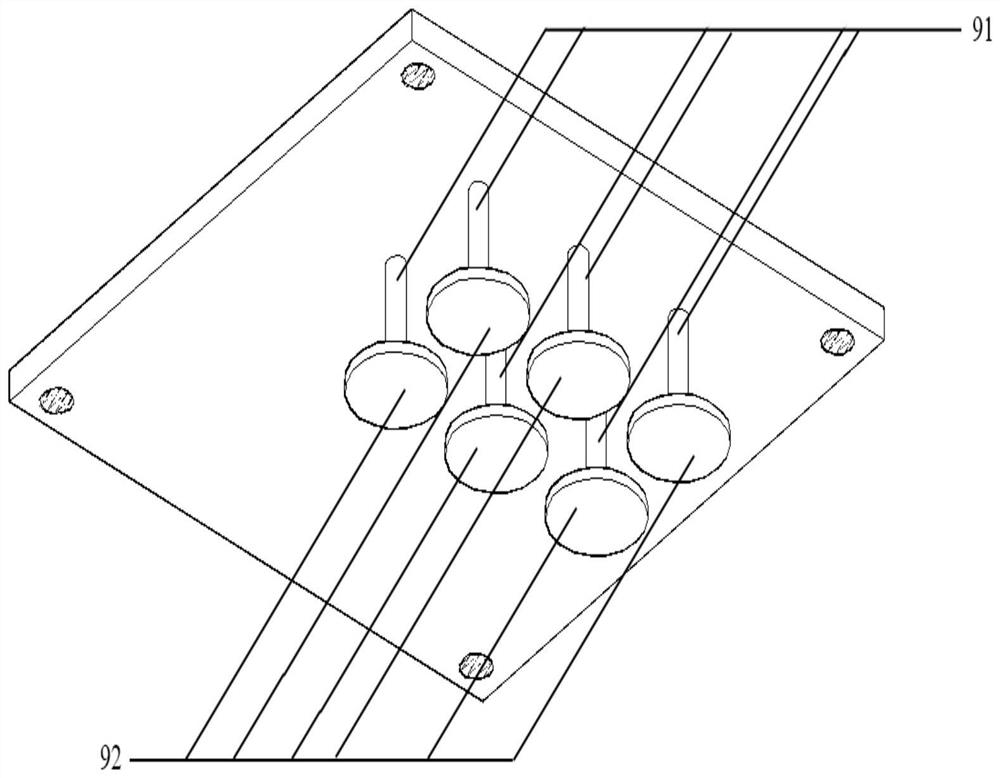

Air tightness test equipment

InactiveCN104198127AAvoid manual repetitive actionsOvercome cumbersome operationsFluid-tightness measurement using fluid/vacuumAutomotive engineeringTest fixture

The invention relates to air tightness test equipment comprising a frame, a test die, a test mold, a plurality of test cylinders, a test fixture and a jacking mechanism. During actual use, a to-be-tested workpiece is placed on the test fixture, the air tightness test equipment is started, the jacking mechanism acts to jack the test fixture with the workpiece up into the test mold, the test cylinders respectively have the operation tested, and after test is completed, the test cylinders reset, and the jacking mechanism descends to drive the test fixture to descend, so that operation personnel can conveniently take out operation subjected to the test and perform classification according to test results. The workpiece is multidimensionally tested through the test cylinders by the aid of characteristics of product itself, the problem about multi-station test of the product can be solved at one step, manual repetitive operation is avoided, and rapidness is maximized; the shortcoming of personnel operation complexity is overcome, the air tightness test equipment is high in speed and efficient.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

Momordica grosvenori extractive with at least 40 percent grosvenor momordica glycoside and preparation method thereof

InactiveCN100572552CReduce the amount of feedShorten the production cycleFermentationFood preparationGlycosideSocial benefits

The invention provides a milk white fructus momordicae extract, fructus momordicae glycoside V and fructus momordicae glycoside of which are respectively larger than or equal to 40 percent and 98 percent. The invention also discloses a preparation method of the extract. Using fresh fructus momordicae as the raw material, the invention is obtained through the water extraction, the concentration, the enzymatic hydrolysis, the macroporous adsorption resin refining, the ion exchange resin decoloration, the concentration and the spray drying. The invention is characterized in that the process parameters of the steps which are suitable for the industrial production are found, the yield and the quality of the fructus momordicae extraction are all obviously improved, and obvious economic benefits and social benefits are obtained.

Owner:GUILIN HUITONG BIOTECH

Method for producing benzaldehyde by oxidizing dibenzyl ether by air

InactiveCN102775285AIncrease added valueOvercome cumbersome operationsOrganic compound preparationCarbonyl compound preparationBenzaldehydeChemistry

The invention discloses a method for producing benzaldehyde by oxidizing dibenzyl ether by air, comprising the following steps: feeding the dibenzyl ether produced in the benzaldehyde working section into a dibenzyl ether head tank, carrying out the benzaldehyde pilot production after the liquid level is more than 60% of the height of the dibenzyl ether head tank; adding material into an electric heating reactor from the dibenzyl ether head tank until the liquid level is 80% of the height of the electric heating reactor, and heating to increase temperature; obtaining the water in the dibenzyl ether by steaming, and pouring the water removed by steaming into the benzaldehyde working section; after finishing obtaining the water by steaming, increasing the temperature of the electric heating reactor so that the oil-phase material in a return pipe reflows; introducing air into the electric heating reactor, decreasing the temperature of the electric heating reactor along with reaction; stopping heating when the temperature of the electric heating reactor decreases to 200-210 DEG C; stopping introducing air when the temperature of the electric heating reactor continuously decreases to 190-200 DEG C; pumping the material in the electric heating reactor into a rectifying reactor under the vacuum condition; obtaining light components by steaming by a rectifying tower, and performing secondary refining on the light components via recycling; obtaining the finished product which is the benzaldehyde by steaming, putting the benzaldehyde into a barrel, and packaging; obtaining heavy components by steaming, and performing secondary refining on the components via recycling; removing slag; and analyzing the finished product which is the benzaldehyde by using the gas chromatography. The benzaldehyde is colorless and transparent, and has the fragrant bitter almond flavor.

Owner:聊城鲁西氯苄化工有限公司

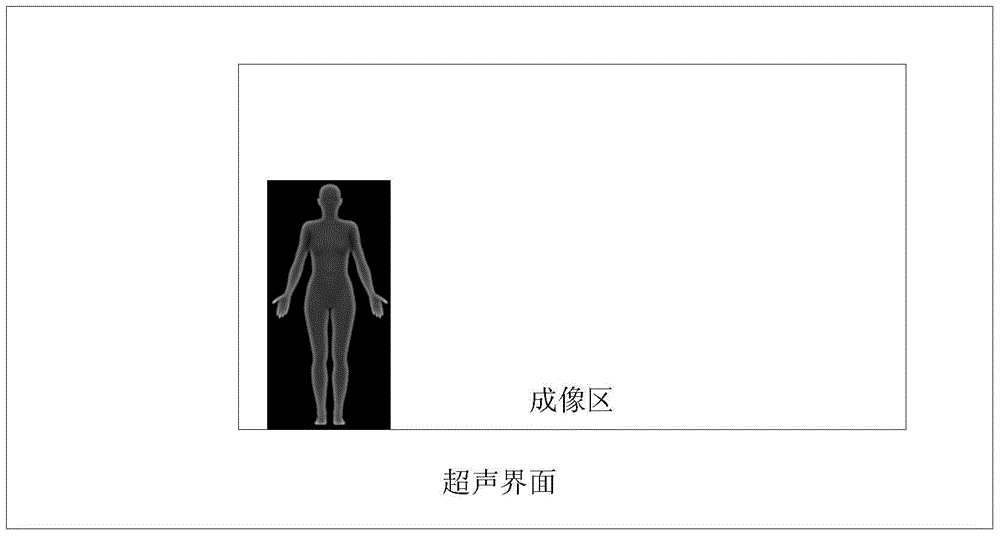

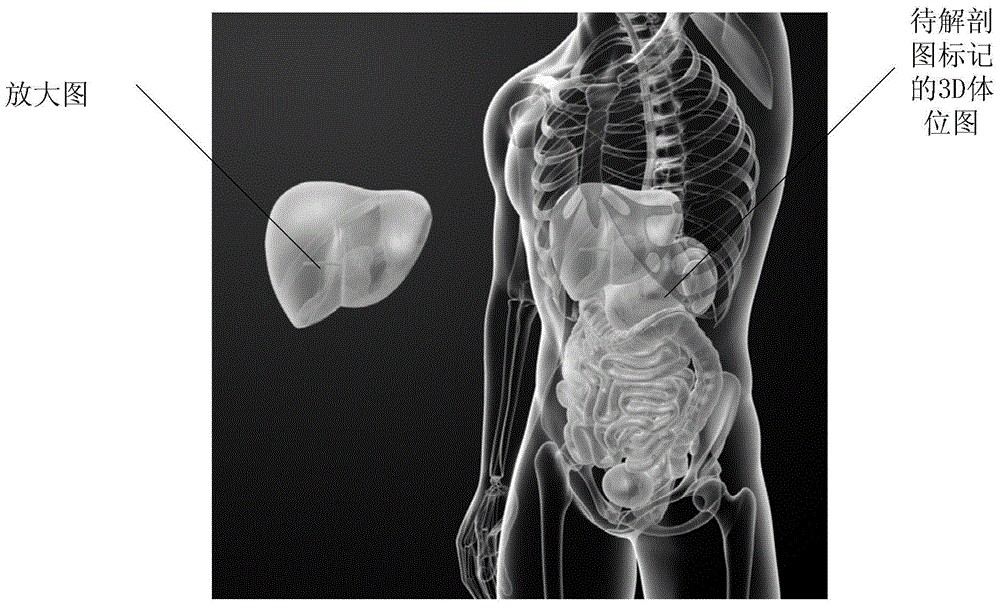

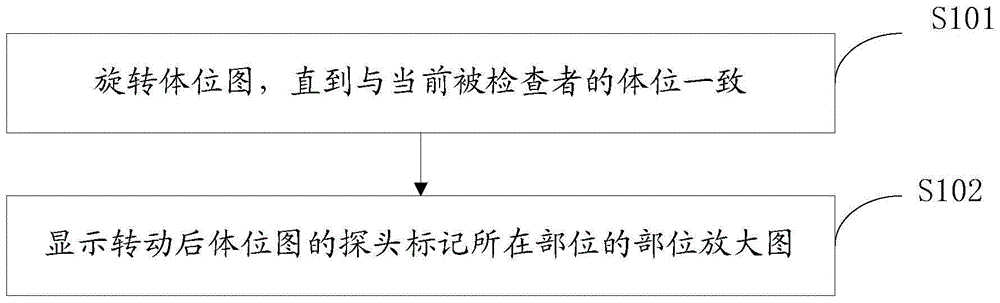

Body position icon, adding method, control device and ultrasonic equipment of control device

PendingCN105662466AConvenient and accurate determinationImprove convenienceUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsRaster graphicsBody positions

The invention provides a body position icon. The body position icon is located at the position, used for identifying ultrasonic examination, of an ultrasonic display interface and is a three-dimensional body position icon; the invention further provides a control device and equipment for the body position icon. By means of the body position icon, different positions of the three-dimensional body position icon can be marked according to a probe, thereby an operator can determine the examination position conveniently and accurately, operation convenience of doctors is improved, and meanwhile the aesthetic effect is enhanced.

Owner:SONOSCAPE MEDICAL CORP

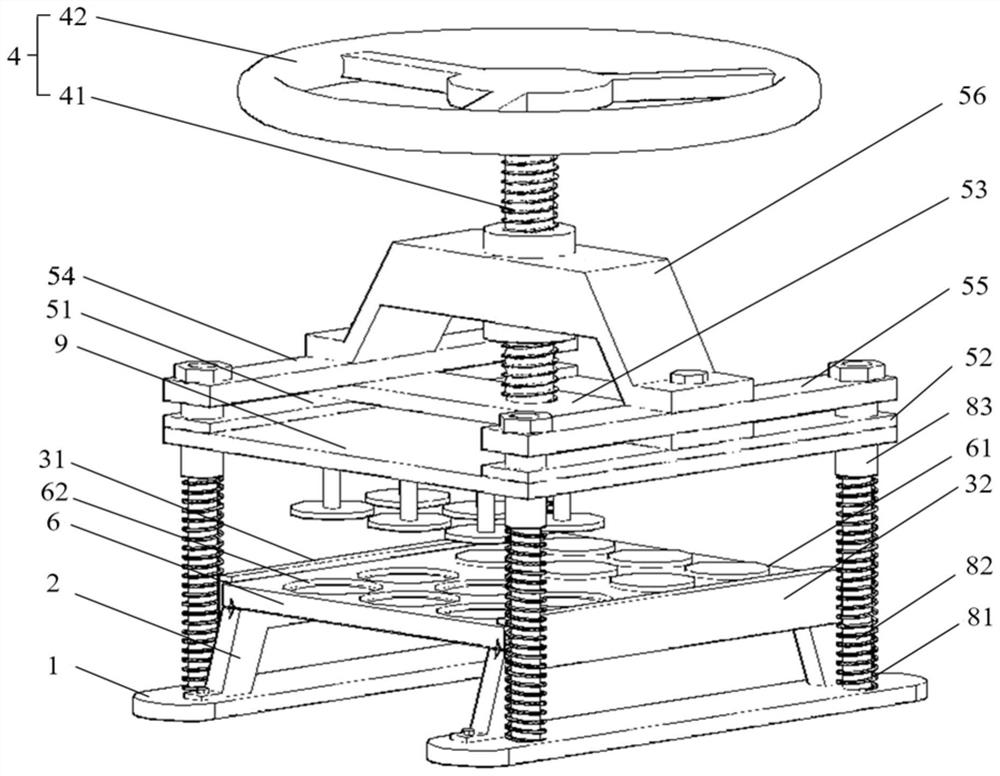

Soil post sample making machine

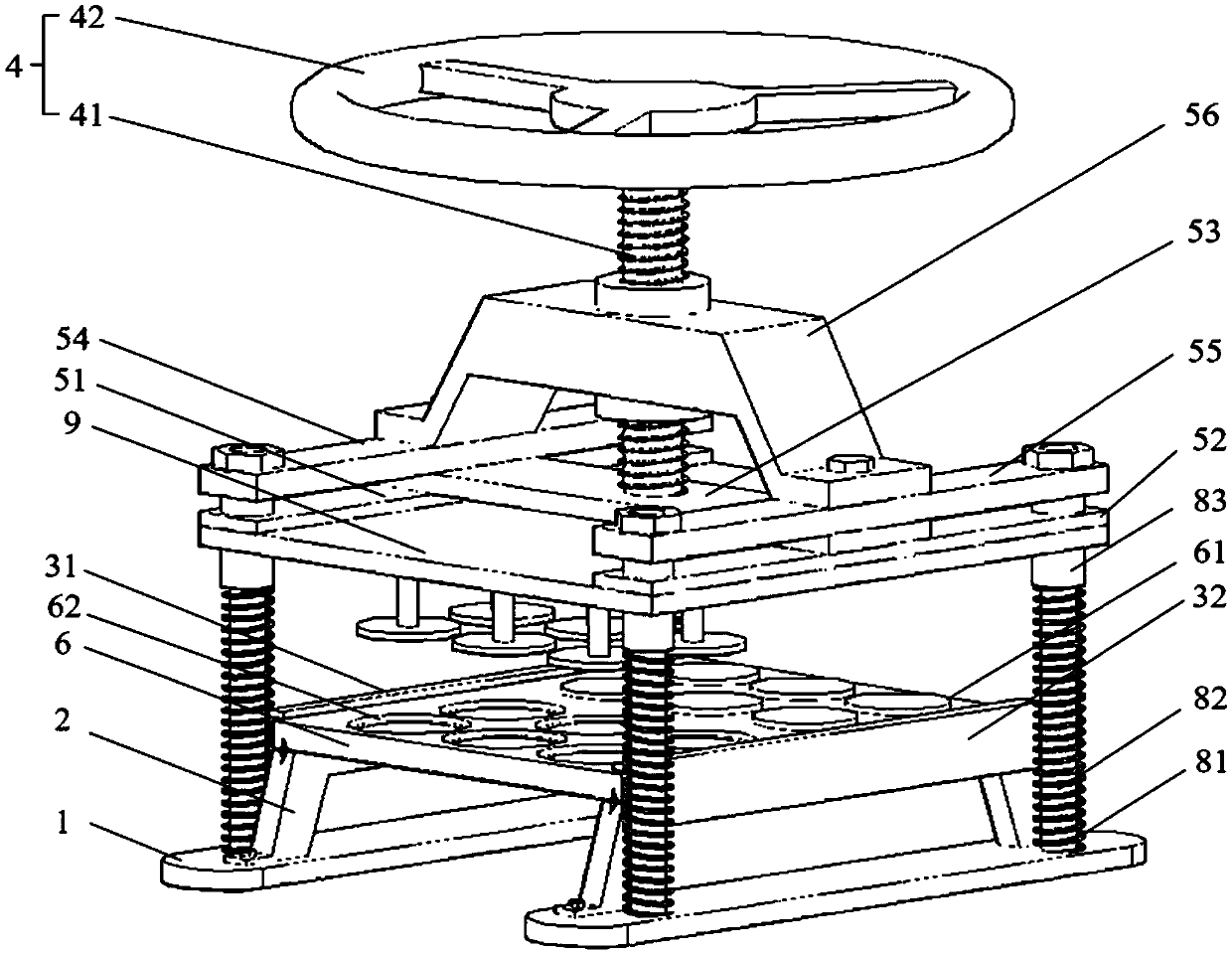

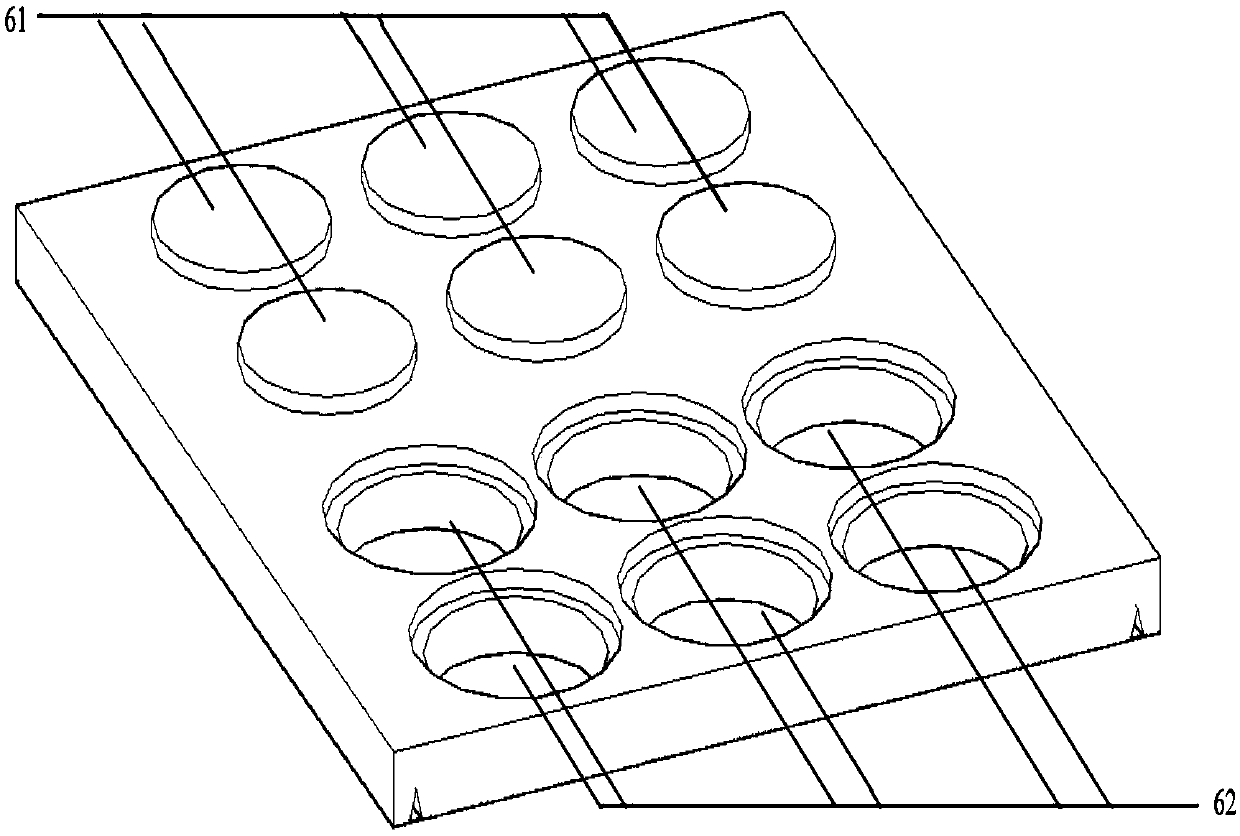

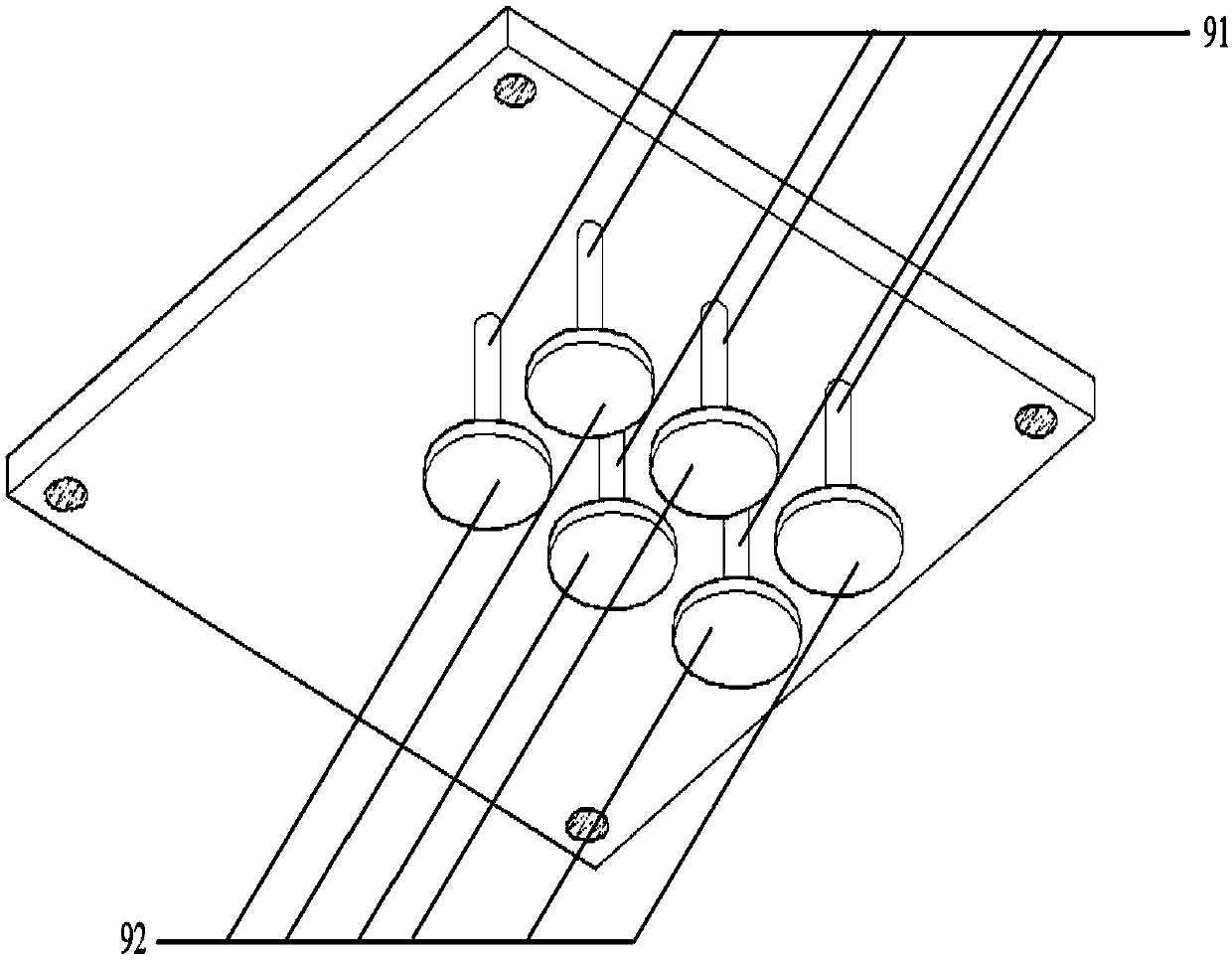

ActiveCN109668769AEven by forceEliminate the step of desamplingPreparing sample for investigationPunchingEngineering

The invention belongs to the field of geotechnical tests, and discloses a soil post sample making machine. The soil post sample making machine comprises a base, a base table frame, a position limitingassembly, a driving assembly, a supporting support frame, a punching plate, a mold plate, a spring, a sample making tube and a pad block, wherein the base table frame is welded at the upper end of the base; the upper end of the supporting support frame supports the driving assembly; the driving assembly drives the punching plate to vertically slide; the mold plate horizontally slides between thebase table frame; the sample making tube is put on the mold plate; the pad block is arranged at the upper side of the sample making tube; the position limiting assembly is fixedly arranged on the basetable frame; the lower end of the spring is abutted and connected with the base. The structure is simple; the operation is convenient; precision and high efficiency are realized; in the sample makingprocess, the soil post stress is uniform; the manufactured soil posts have basically identical height, flatness and dry density; the quality of the manufactured soil posts can meet the test teachingrequirements of scientific research and college and university geotechnical tests; the manufacturing efficiency of the soil posts is greatly improved; a great amount of labor is saved.

Owner:CENT SOUTH UNIV

Balance hanger for motor rotor

InactiveCN105366529AOvercome cumbersome operationsSimple and efficient operationLoad-engaging elementsBatch productionSerialization

The invention discloses a balance hanger for a motor rotor and particularly relates to a balance hanger for a motor rotor. The balance hanger mainly aims to solve the problems that general rotor hangers sling motor rotors by adopting a mode that lifting holes in L-shaped lifting arms are threaded with steel wire ropes, fine control or fine tuning for balance of the rotors cannot be achieved, manual assisting balance is required, and when the rotors are adjusted to be horizontal, the steel wire ropes need to be threaded and pulled out for a plurality of times, the operation is inflexible and troublesome, and the production efficiency is low. According to the balance hanger, a right-angled arm of an L-shaped lifting arm is provided with a row of uniformly aligned pin holes, a hanging hook is fixed in one of the pin hole of the L-shaped lifting arm through a pin, and a copper bush is fixed to the end of the other right-angled arm of the L-shaped lifting arm. When the balance hanger is used for lifting, the horizontal position of the motor rotor can be guaranteed by using a crown block to sling the hanging hook, and horizontal lifting of the motor rotor can be achieved under the condition that threading and pulling out of a steel wire rope and manual assisting balance are not needed. The balance hanger is simple in structure, simple and convenient to operate, efficient, and suitable for serialization and batch production of motors.

Owner:襄阳中车电机技术有限公司

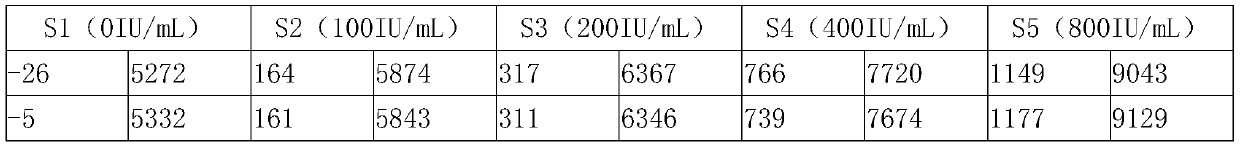

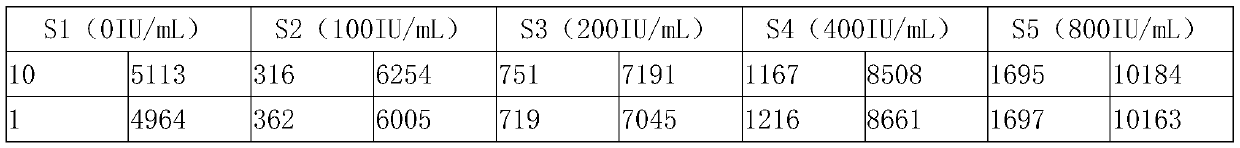

Method for coupling carboxyl microspheres with amino groups, sensitizing latex and kit

PendingCN111579767AEfficient couplingOvercome cumbersome operationsMaterial analysisBlood serumAntiendomysial antibodies

The invention provides a method for coupling carboxyl microspheres with amino, sensitizing latex and a kit, and belongs to the technical field of medical reagents. The method comprises the following steps: dropwise adding a CDI solution into a latex microsphere solution, and oscillating and uniformly mixing to obtain activated latex microspheres; adding a coupling buffer solution into the activated latex microspheres to adjust the pH value; adding an antibody into the solution of which the pH value is adjusted, and oscillating and uniformly mixing to obtain a coupled solution; and adding the bovine serum albumin mother liquor into the coupled solution, and oscillating and uniformly mixing to obtain the sensitizing latex. The invention also provides the sensitizing latex prepared by the preparation method. The invention also provides a kit containing the sensitizing latex. The method is high in coupling efficiency and low in cost, and the obtained kit is excellent in performance.

Owner:JILIN GETEIN BIOTECH CO LTD

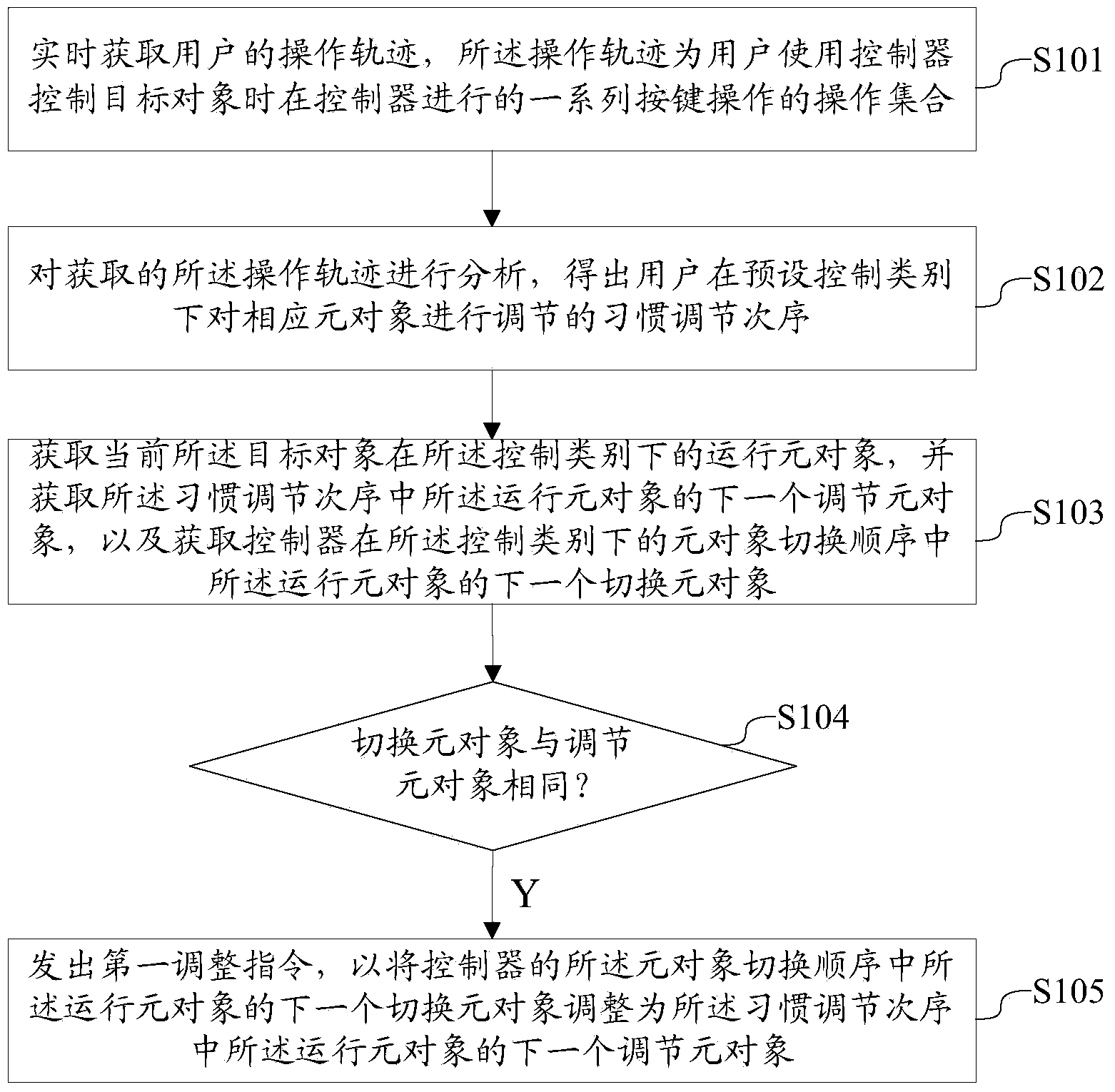

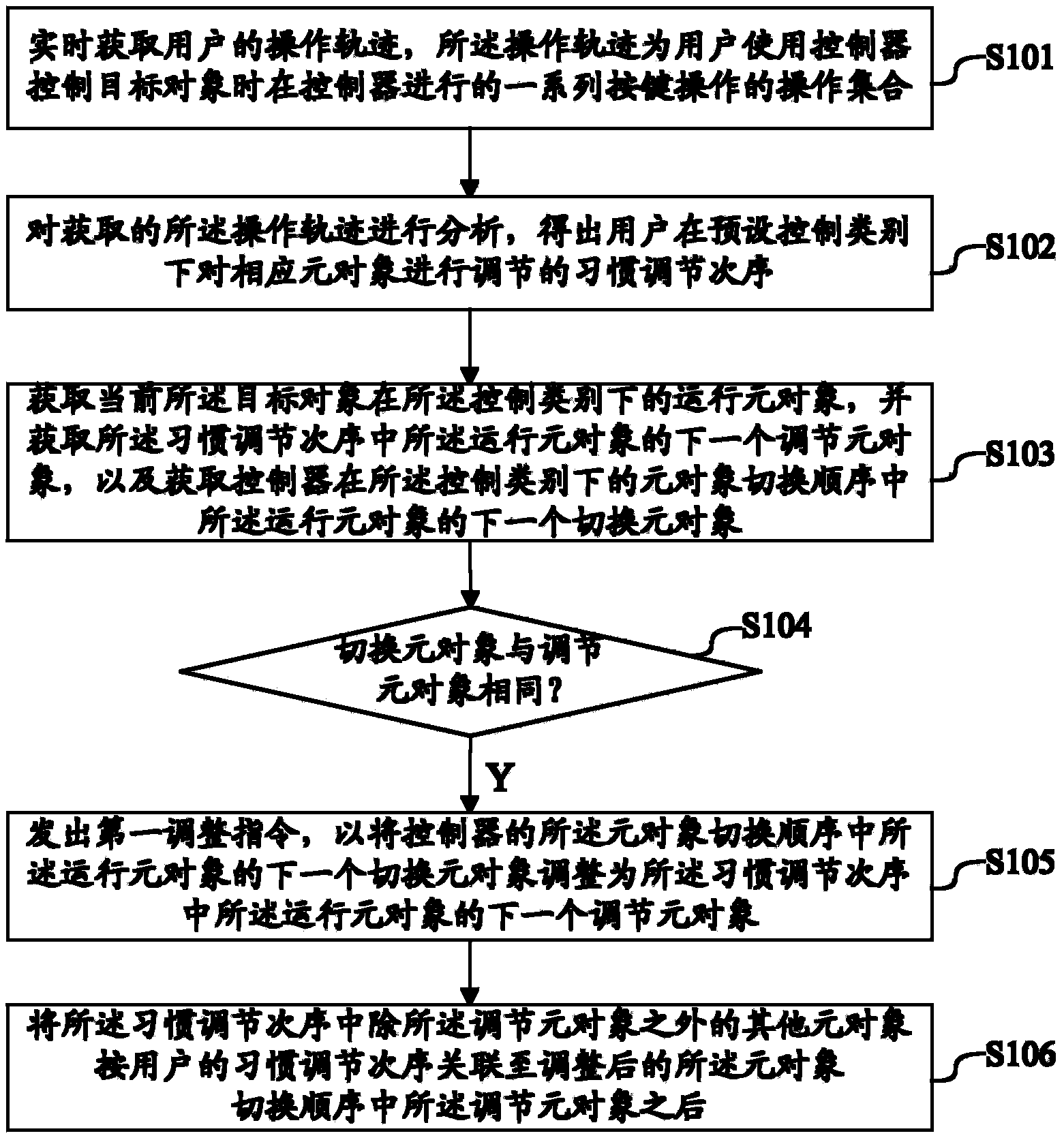

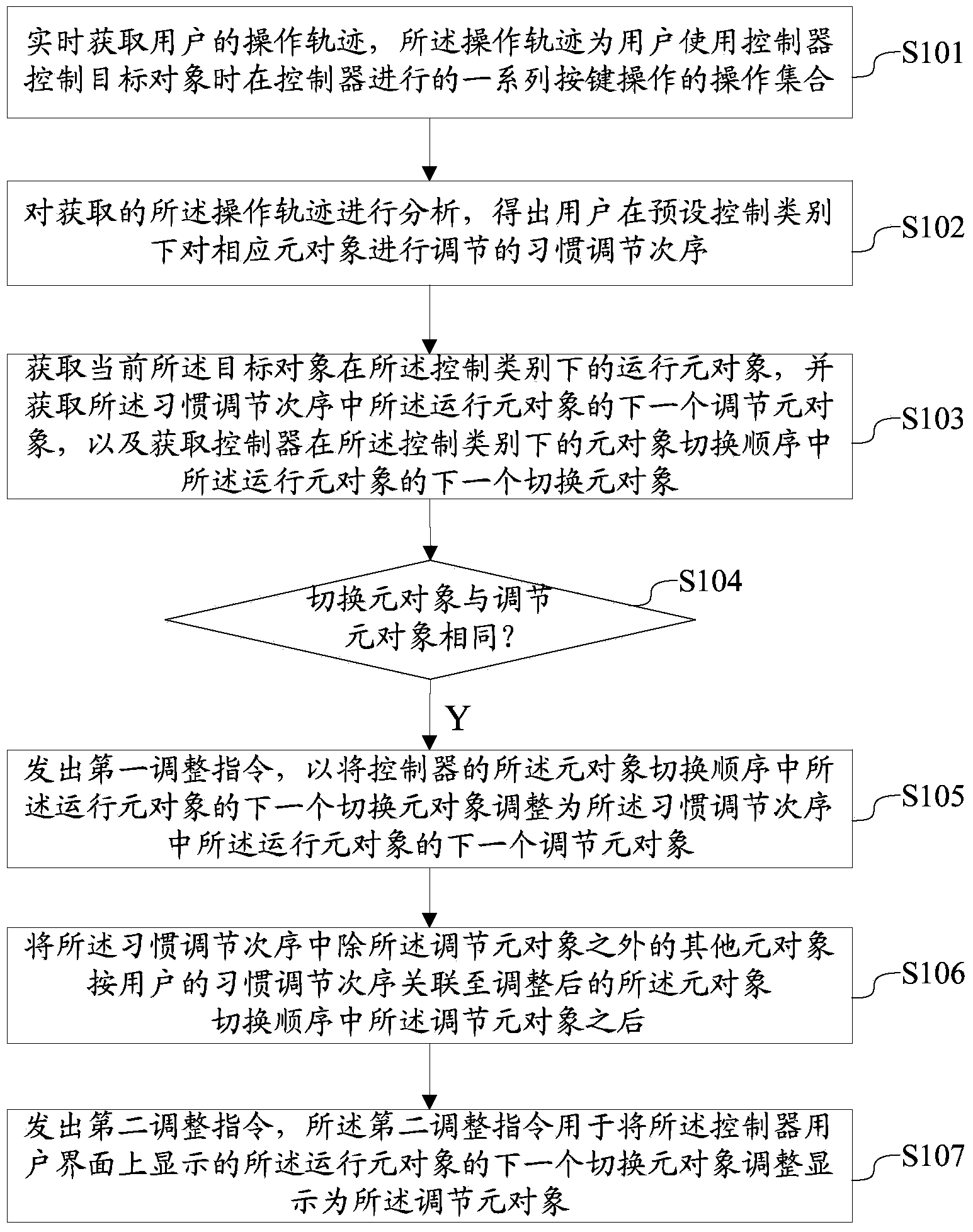

Control adjustment method and device and air conditioner controller

ActiveCN104266313AOvercome cumbersome operationsMechanical apparatusSpace heating and ventilation safety systemsHabitComputer science

The invention discloses a control adjustment method and device and an air conditioner controller. The method comprises the following steps: acquiring an operation trajectory of a user and analyzing the operation trajectory to obtain a habitual adjustment order for adjusting a corresponding meta object by a user under a preset control category; when a next switching meta object of a meta object operated under the control category by a current target object (such as an air conditioner) is different from a next adjusting meta object of the operated meta object in the habitual adjustment order, adjusting the next switching meta object of the operated meta object in a corresponding meta object switching sequence of a controller to the adjusting meta object. Thus, the control method of the controller is adjusted according to the usage habit of a user, and the defects that the air conditioner control is complex in operation and is not humanized existing in the prior art are overcome.

Owner:GREE ELECTRIC APPLIANCES INC

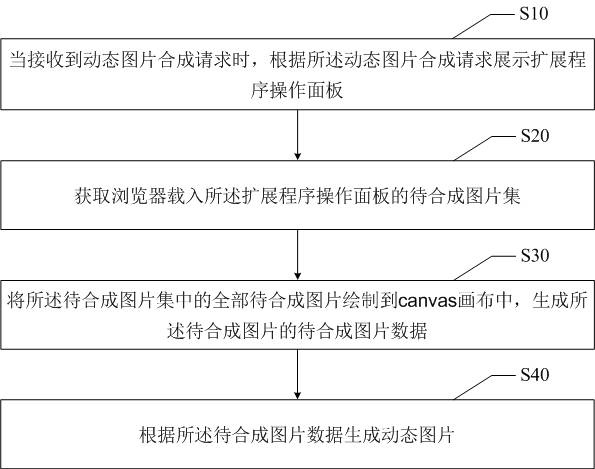

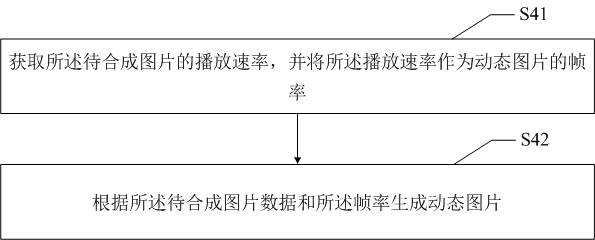

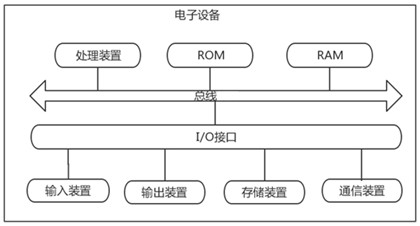

Dynamic picture synthesis method and device thereof, electronic equipment and readable storage medium

ActiveCN113676677AAvoid CatonOvercome cumbersome operationsTelevision system detailsDrawing from basic elementsComputer graphics (images)Software engineering

The invention discloses a dynamic picture synthesis method and a device thereof, electronic equipment and a readable storage medium, and the method comprises the steps: displaying an extension program operation panel according to a dynamic picture synthesis request when the dynamic picture synthesis request is received; obtaining a to-be-synthesized picture set loaded into the extension program operation panel by a browser; drawing all the to-be-synthesized pictures in the to-be-synthesized picture set into a canvas, and generating to-be-synthesized picture data of the to-be-synthesized pictures; and generating a dynamic picture according to the picture data to be synthesized. The technical problem that in the prior art, dynamic picture synthesis operation is tedious is solved.

Owner:深圳市明源云空间电子商务有限公司

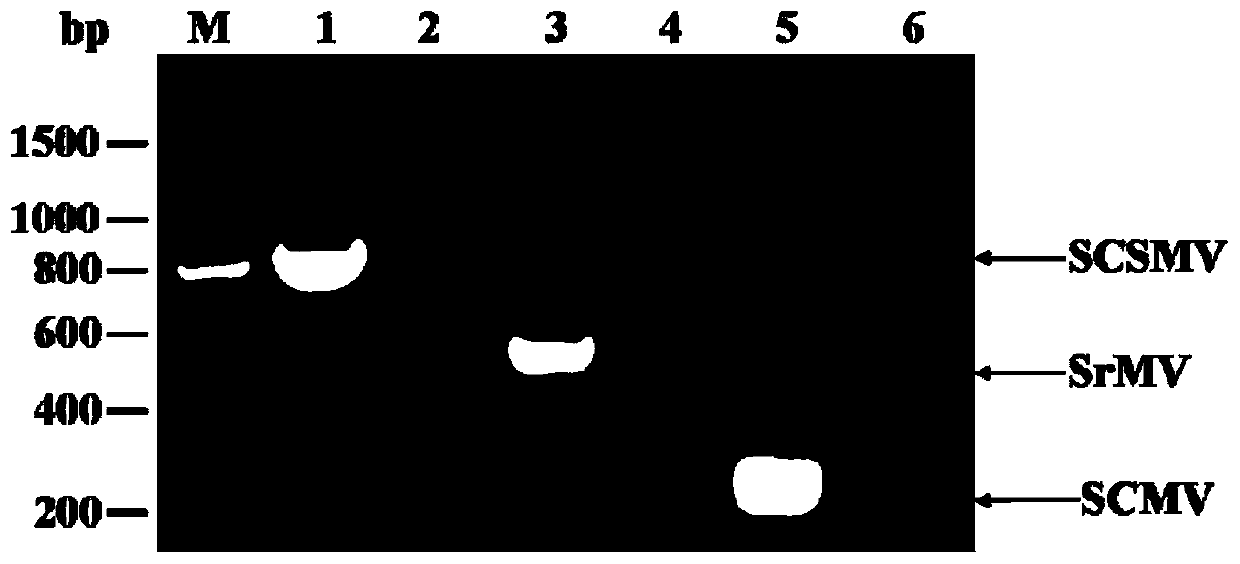

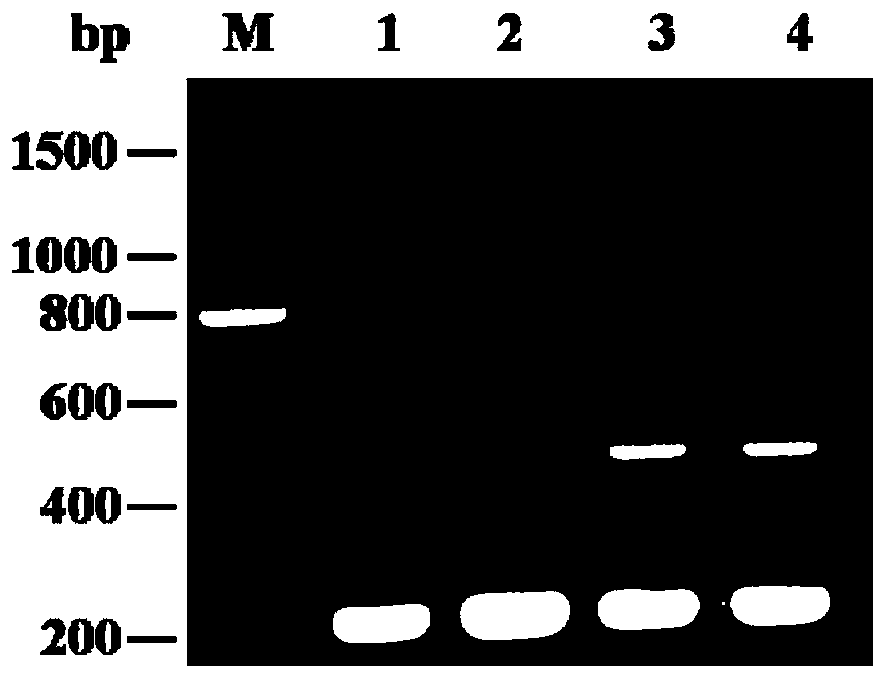

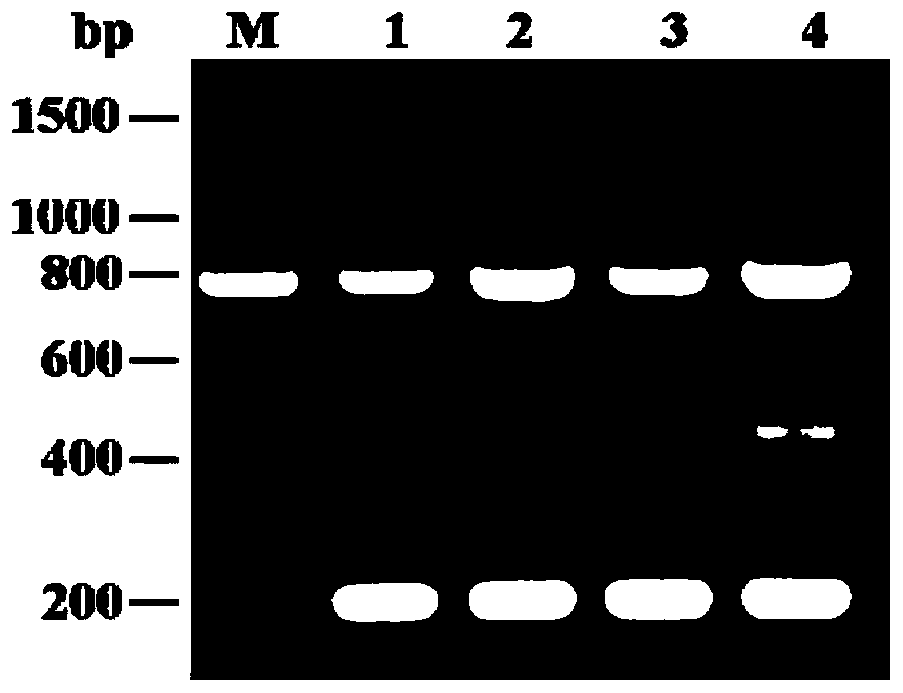

One-step multiple RT-PCR detection method for simultaneously detecting 3 pathogens of sugarcane mosaic diseases

InactiveCN110951924AStrong specificityAccurate specificityMicrobiological testing/measurementDNA/RNA fragmentationDiseaseGermplasm

The invention discloses a one-step multiple RT-PCR detection method for simultaneously detecting 3 pathogens of sugarcane mosaic diseases. Through specific primers on sugarcane streak mosaic viruses,sorghum mosaic viruses and sugarcane mosaic viruses and the optimizing of specific primer concentrations, enzyme dosage and annealing temperatures, the reverse transcription and PCR amplification of the 3 pathogens can be established in a same reaction tube through one-time RT-PCR reaction; the multiple RT-PCR detection method simultaneously accomplished in one step under a same reaction conditionis simple in operation step; repeated detection of conventional RT-PCR or complex two-step multiple RT-PCR reaction steps and programs, long time consumption and cross contamination can be avoided; and the method has the characteristics of being simple, efficient, strong in specificity and high in sensitivity, can be used for the production, application, germplasm exchange and introduction quarantine of sugarcane virus-free and healthy seedlings, and has important significance on preventing and controlling the spreading of sugarcane mosaic diseases.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI

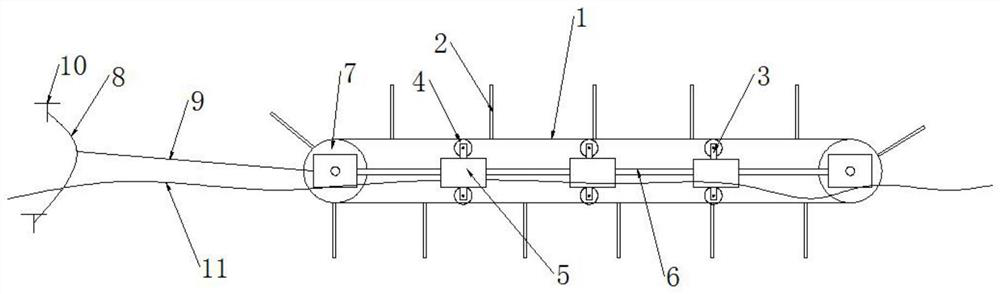

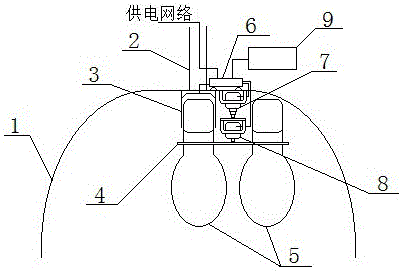

Suspension chain hydroelectric power generation waterwheel device

PendingCN112814821AIncrease contact areaIncrease power generationHydro energy generationEngine componentsWater wheelEcological environment

The invention discloses a suspension chain hydroelectric power generation waterwheel device, and relates to the technical field of power generation devices. The suspension chain hydroelectric power generation waterwheel device comprises a chain which is rotationally arranged along a downstream direction, wherein water stirring plates are uniformly fixed on an outer ring of the chain, and a plurality of position-fixed generator sets are arranged on an inner ring of the chain. The suspension chain hydroelectric power generation waterwheel device solves the problems that the power generation mode of a device in the prior art is low in generating capacity, operation is tedious due to the fact that piling and fixing are needed, and influence on a river channel and a surrounding ecological environment is great and ecology is prone to be destroyed due to the fact that the device is tedious in construction.

Owner:WEIFANG XINLIMENG AQUATIC TECHN

A Soil Column Prototyping Machine

ActiveCN109668769BEven by forceEliminate the step of desamplingPreparing sample for investigationSoil scienceSoil column

Owner:CENT SOUTH UNIV

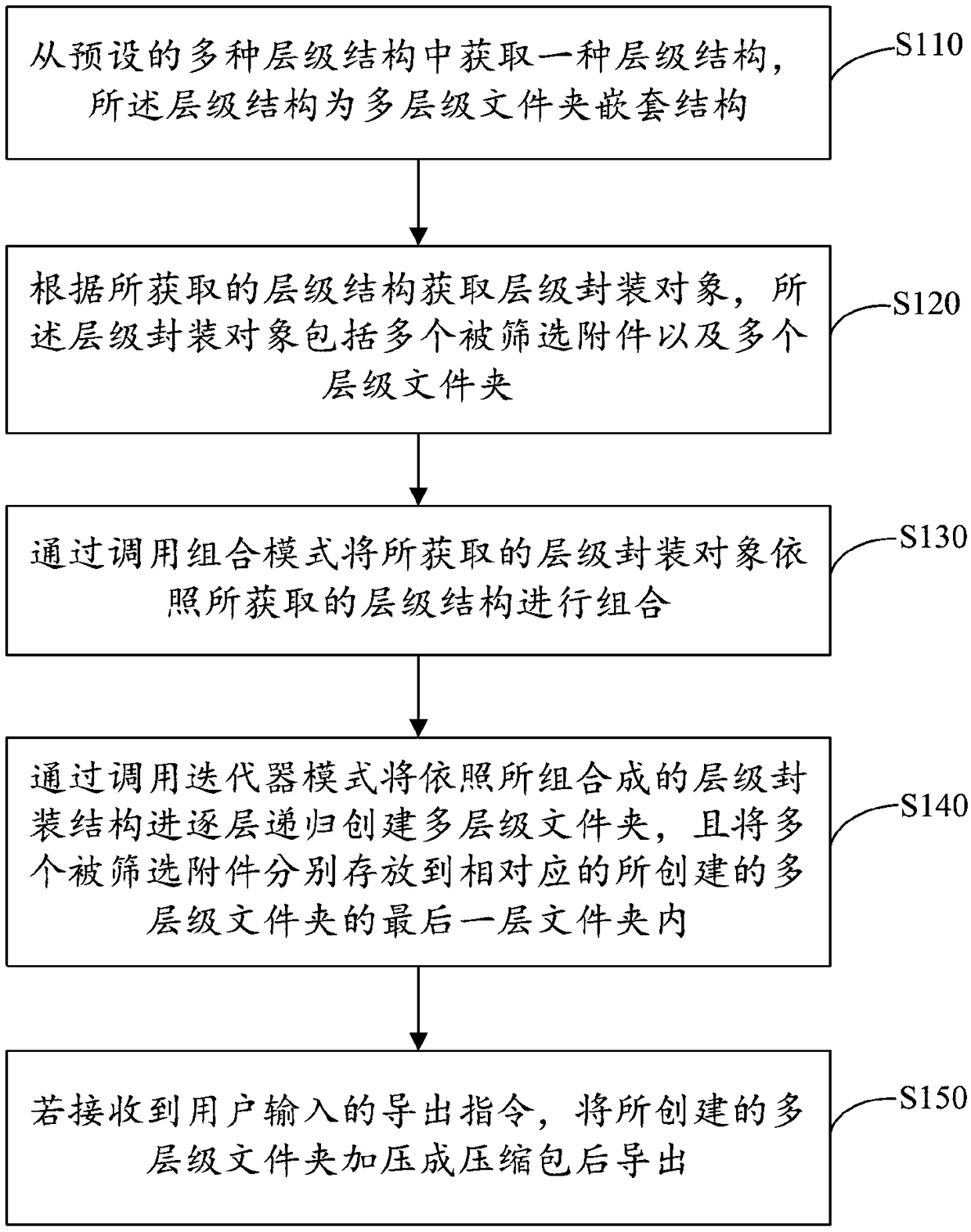

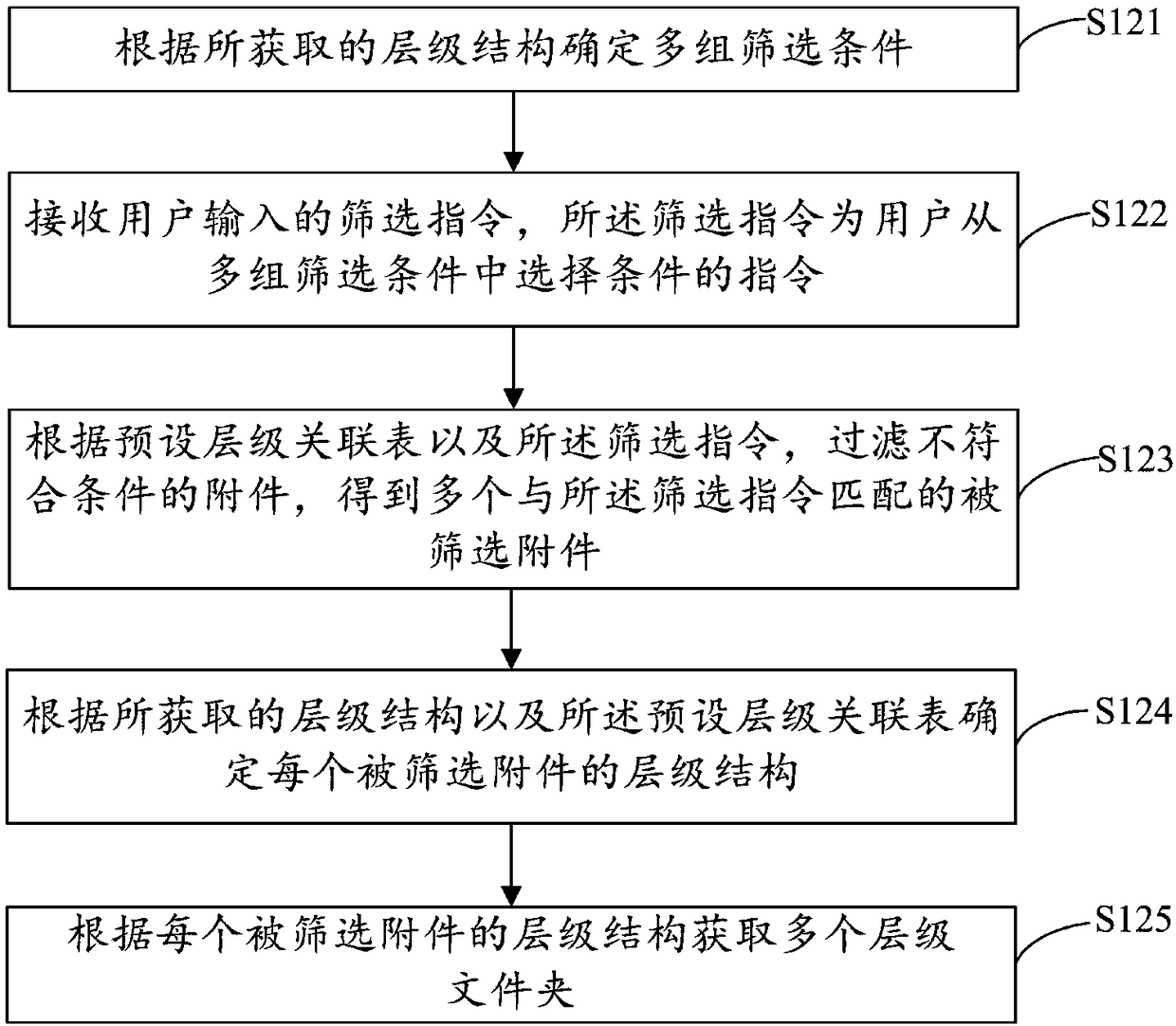

Attachment exporting method, device, compute device, and computer-readable storage medium

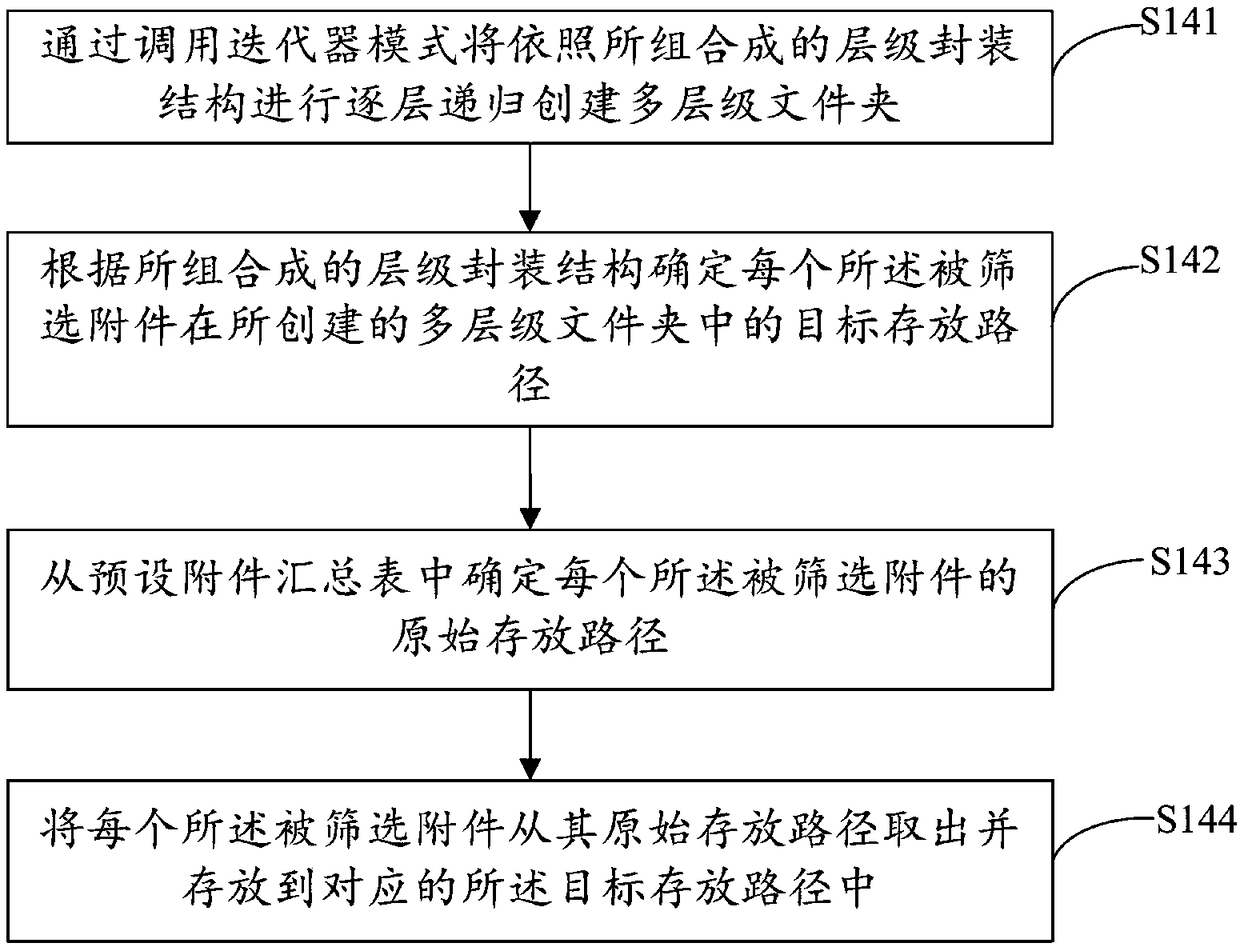

PendingCN109240996AImprove experienceOvercome cumbersome operationsFile system administrationFile/folder operationsUser inputIterator

The invention discloses an attachment exporting method, device, a compute device, and a computer-readable storage medium. The method comprises the following steps: obtaining a hierarchical encapsulation structure from a preset plurality of hierarchical encapsulation structures; Obtaining a hierarchical encapsulation object according to the obtained hierarchical encapsulation structure, wherein thehierarchical encapsulation object comprises a plurality of filtered attachments and a plurality of hierarchical folders; combining the obtained hierarchical encapsulation object according to the obtained hierarchical encapsulation structure by calling the composition mode; calling the iterator mode to recursively create multi-level folders according to the combined hierarchical encapsulation structure layer by layer, and respectively storing a plurality of filtered attachments in the last level folder of the corresponding created multi-level folders; And if the export instruction inputted bythe user is received, compressing the created multi-level folders into compressed packages and exporting the compressed packages. By implementing the scheme, the problem that the whole operation process is cumbersome caused by multiple searches and multiple downloads when the accessories are exported in batch in the prior art can be solved.

Owner:PING AN TECH (SHENZHEN) CO LTD

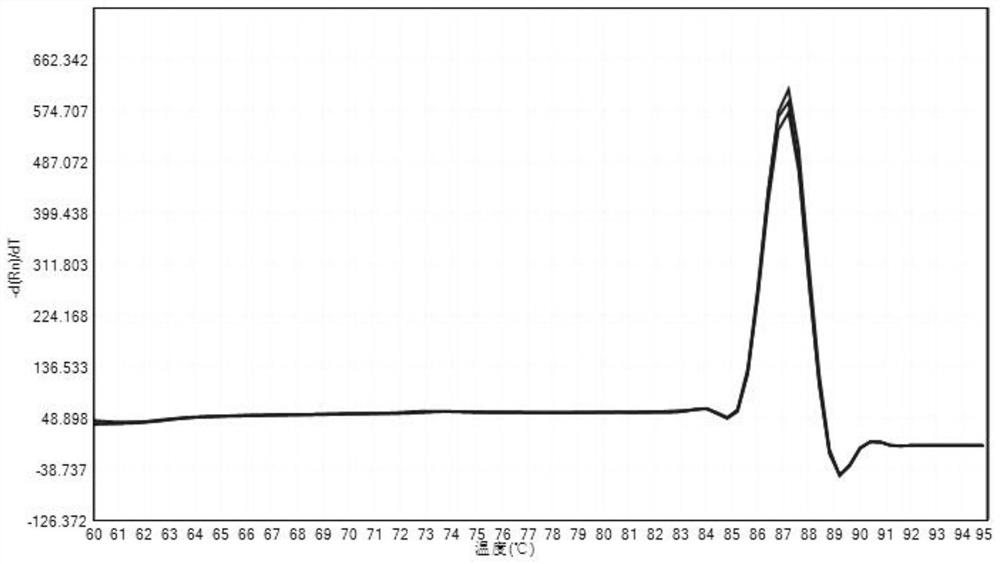

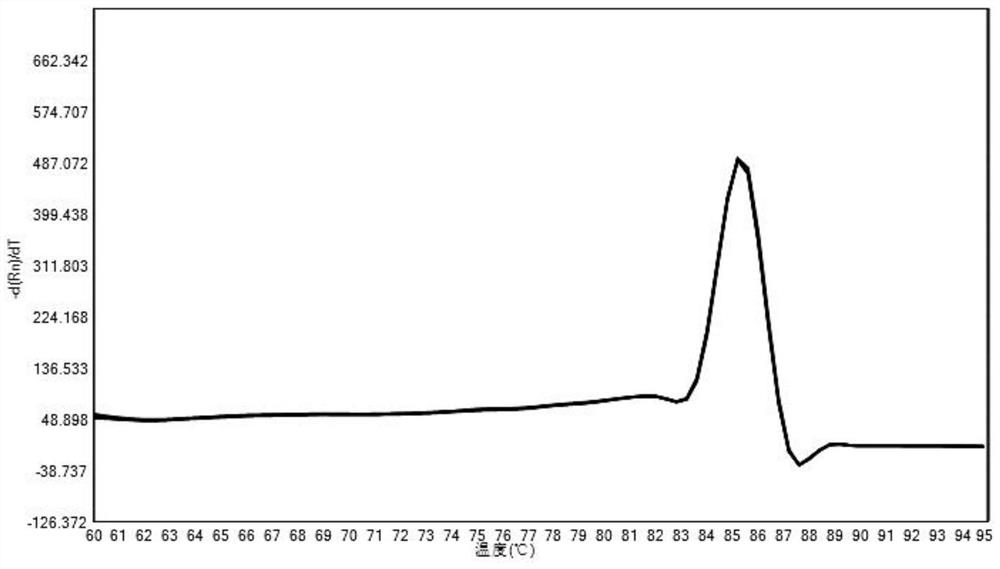

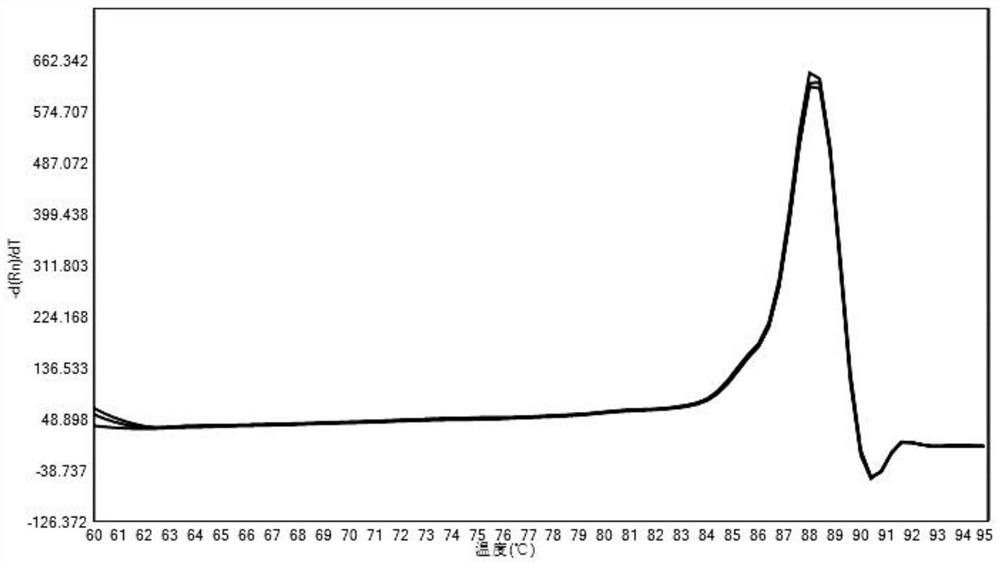

A method for detecting the relative content of bacterial species in a sample

ActiveCN108333159BOvercome cumbersome operationsGuaranteed specificityPreparing sample for investigationFluorescence/phosphorescenceBioinformaticsBiological organism

The invention belongs to the field of biotechnology, and in particular relates to a method for detecting the relative content of bacterial strains in a sample. The steps of the method are as follows: design of primers; genome extraction; fluorescent quantitative PCR; NGS16S sequencing; NGS analysis; Use NGS and qPCR to detect the relative content of a certain bacterium in the sample, and fit and correlate the NGS analysis results with the original qPCR experimental data to establish a predictive model, so that the subsequent qPCR analysis of the sample Test data can be input into the predictive model and directly obtain the relative content of a certain bacteria to be tested in the sample. The method reduces the complexity and cumbersome operation of the optimization of the relative content detection experiment of bacteria using qPCR alone, and improves the speed of obtaining the final result of the sample detection; it has great market prospects and economic value.

Owner:深圳谱元科技有限公司

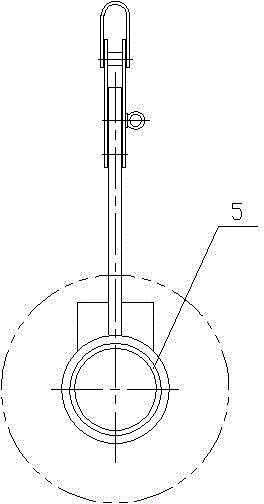

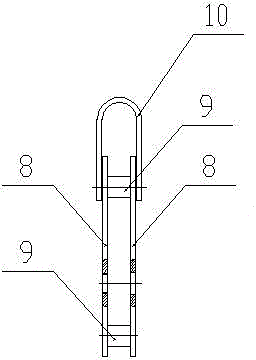

Automatic bulb replacing type lighting device

InactiveCN106678754AOvercome cumbersome operationsRealize intelligent operationLighting support devicesSemiconductor devices for light sourcesElectrical and Electronics engineeringCooperative work

The invention relates to an automatic bulb replacing type lighting device. Improvement is conducted based on an existing lighting device, a wheel disc type multi-bulb intelligent switching mechanism is introduced, all bulbs (5) are movably connected to all through holes in a wheel disc (4), and additionally, by means of the cooperative work of a motor telescopic rod (7) and a rotating motor (8), replacing of one of the bulbs (5) in a bulb power-supplying inserting hole (3) is achieved; and in the whole bulb replacing process, manual operation is not needed, existing complex operation is removed, intelligent operation is achieved, and the using efficiency of a lighting tool is improved effectively.

Owner:JIANGSU ZHISHI TECH CO LTD

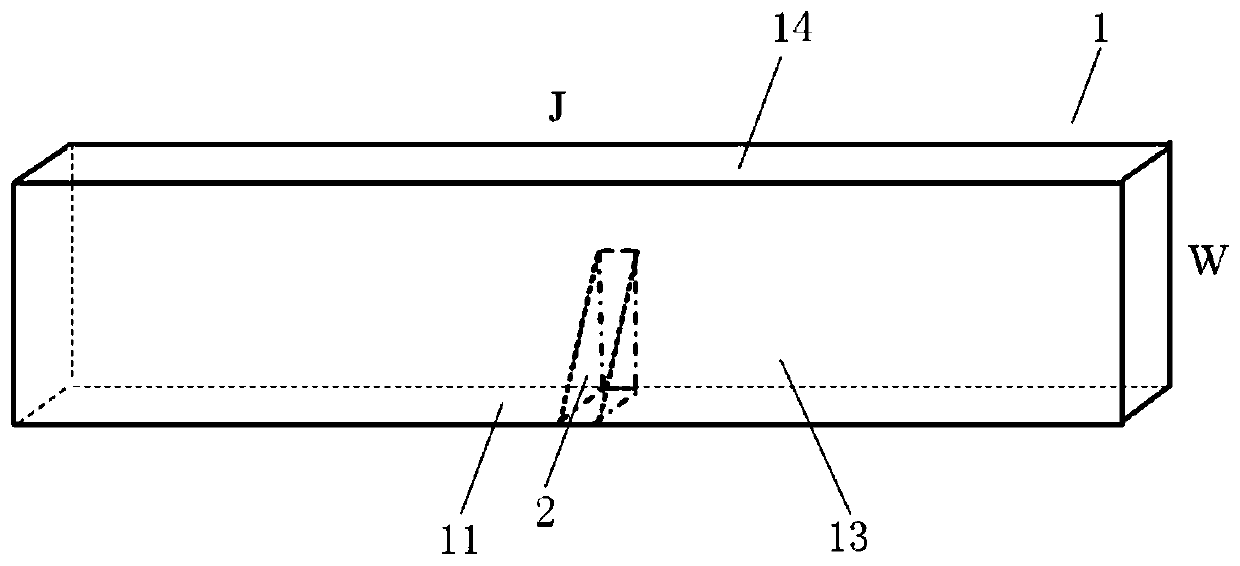

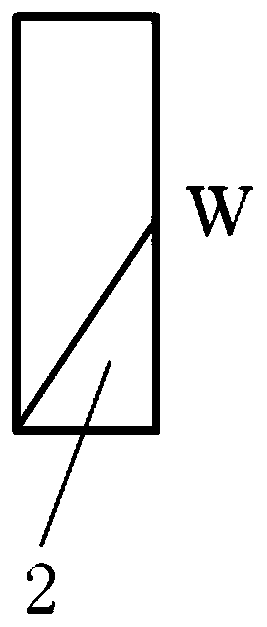

Crack prefabricating method of fragile ceramics, and crack prefabricating support and application thereof

ActiveCN110146360AOvercome cumbersome operationsEasy to operate, effective and convenientPreparing sample for investigationEngineeringCeramic

Owner:CHINA BUILDING MATERIALS ACAD +1

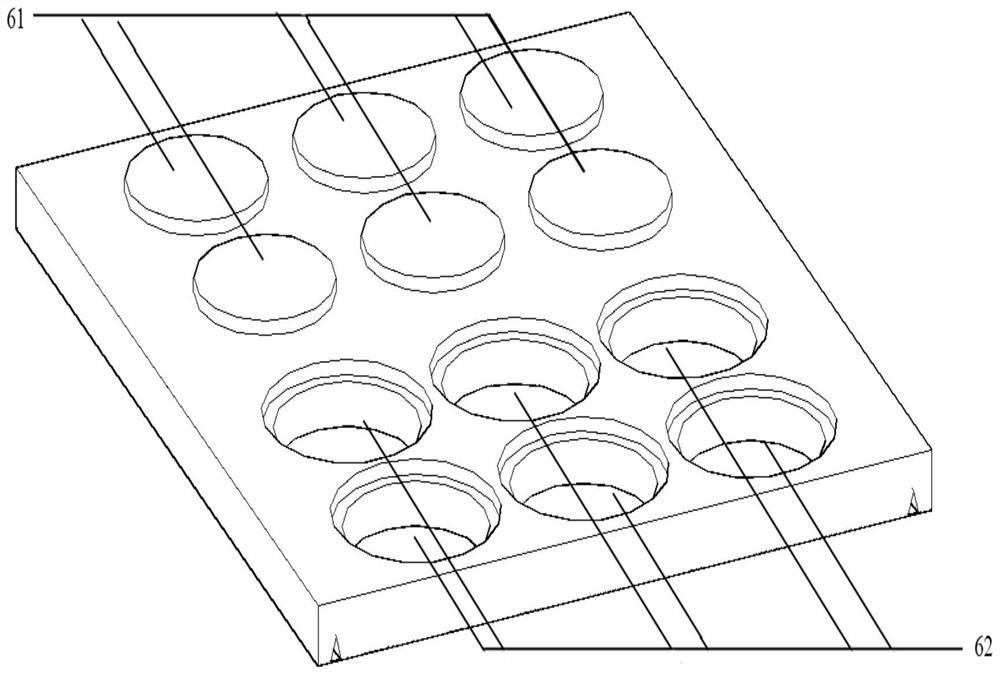

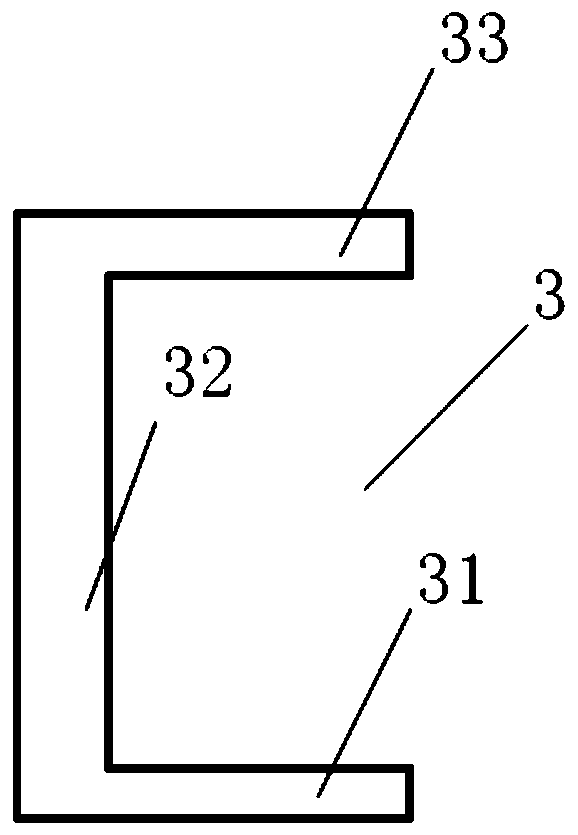

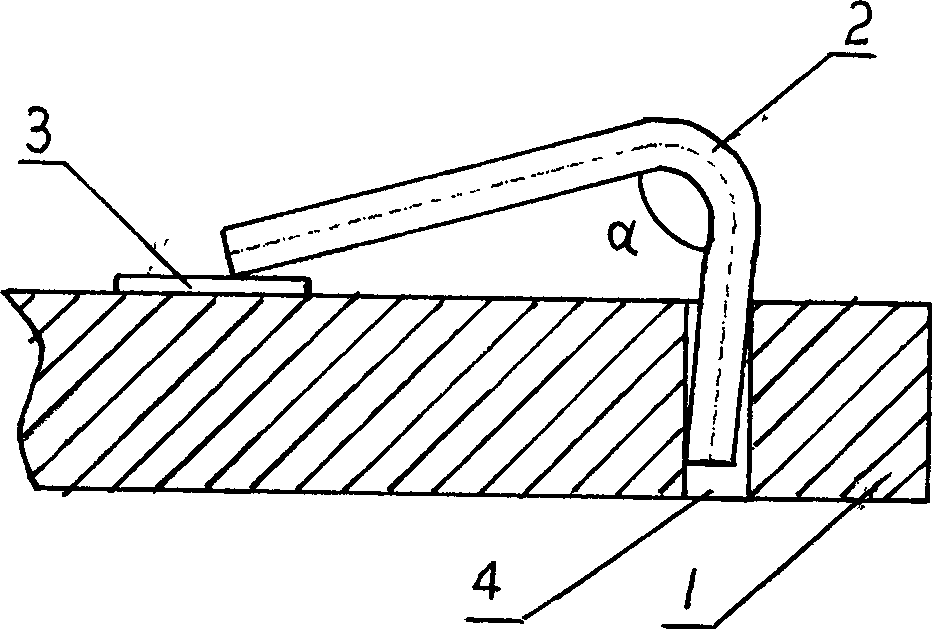

Porous cast iron platform with self-bringing clamping apparatus

InactiveCN101362323AOvercome cumbersome operationsAchieve disassemblyWork benchesCast ironMaterials science

The invention relates to a platform for compacting and fixing a plate part, in particular to a porous type cast iron platform provided with a fixture. The platform comprises a cast iron platform, a fixing hole arranged on the cast iron hole and an L-shaped fixture with one end inserted and arranged inside the fixing hole. The special platform and the fixture are designed, the self-lock principle is adopted between the platform and the fixing, the assembly and the disassembly of a work piece can be realized through simple operation, and the problem of the existing compacting method that the operation is tedious during the multipoint compacting and disassembling is overcome.

Owner:BAODING TIANWEI GRP CO LTD

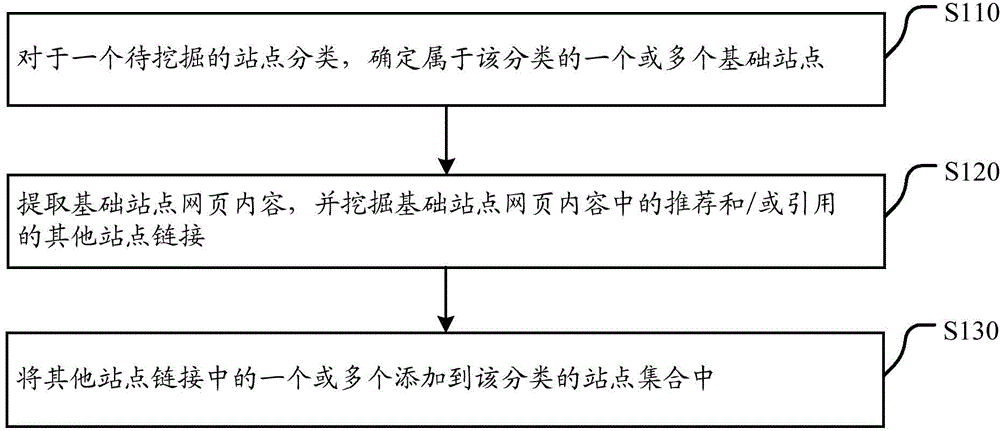

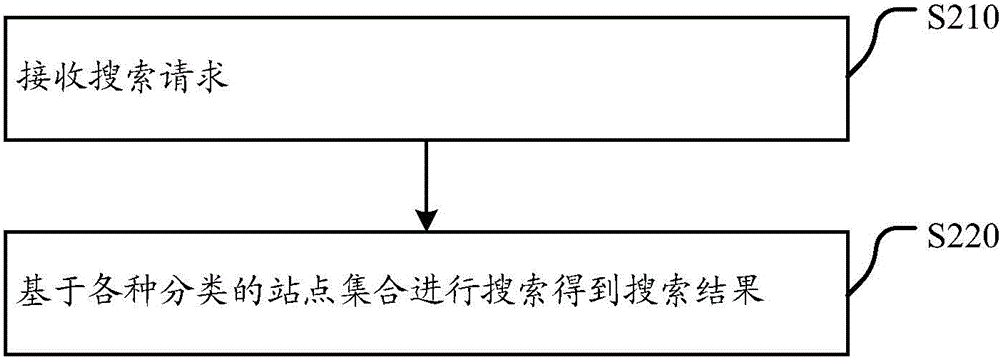

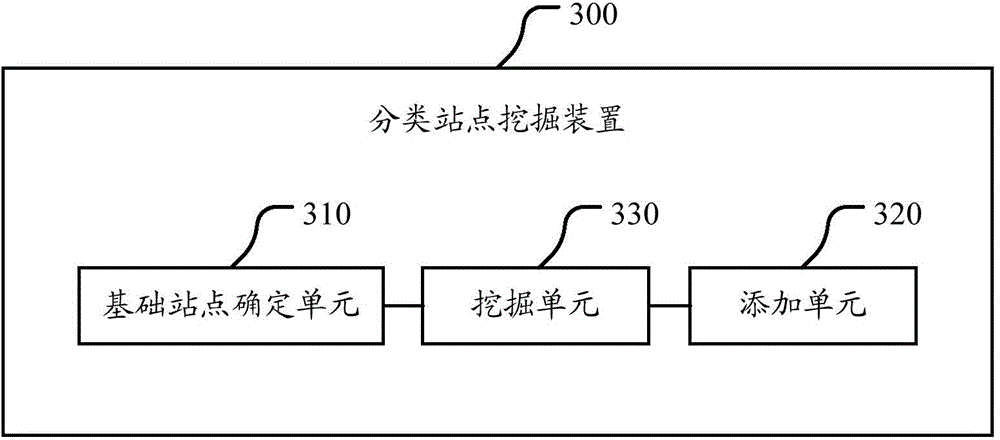

Classified site mining method and device and searching method and system

InactiveCN104537053AThe principle is simple and intuitiveOvercome cumbersome operationsWeb data indexingWebsite content managementData miningWeb page

The invention discloses a classified site mining method and device and a searching method and system. The classified site mining method includes the steps of classifying a site to be mined to determine one or more basic sites belonging to the category; extracting webpage content in the basic site, and mining links, recommended and / or quoted in the webpage content in the basic sites, of the other sites; adding one or more links of the other sites into a site set of the category. According to the technical scheme, the recommendation and quotation relationship of the basic site are utilized for mining the other sites belonging to the same site category with the basic site, and the site set of the category is obtained. According to the technical scheme, the classified site mining method and device and the searching method and system have the advantages of being simple and visual in principle, overcoming defects that in the prior art, operation is complicated, and practicability is poor, being more convenient and effective, being higher in the recall rate and accuracy rate, enabling users to obtain rapid, effective and accurate searching results of the classified sites in the searching process, and meeting searching requirements of the users.

Owner:BEIJING QIHOO TECH CO LTD +1

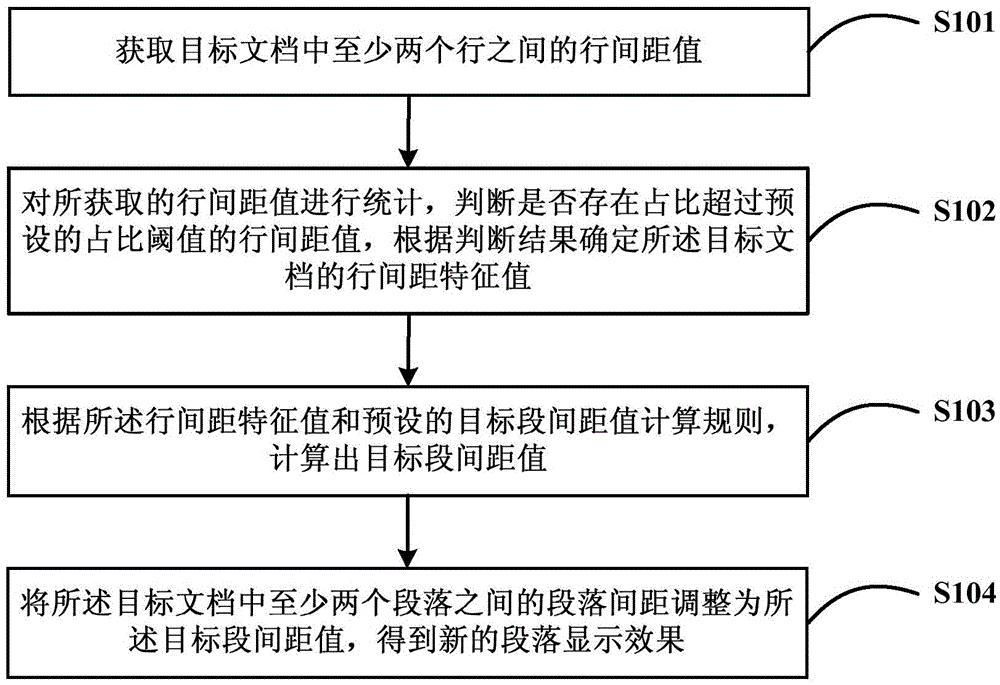

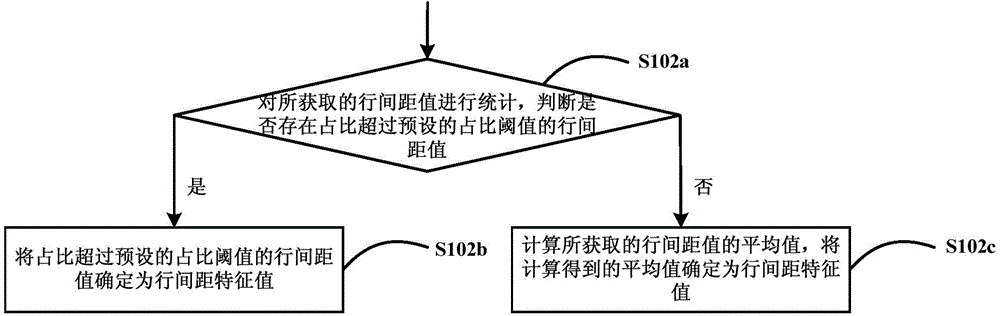

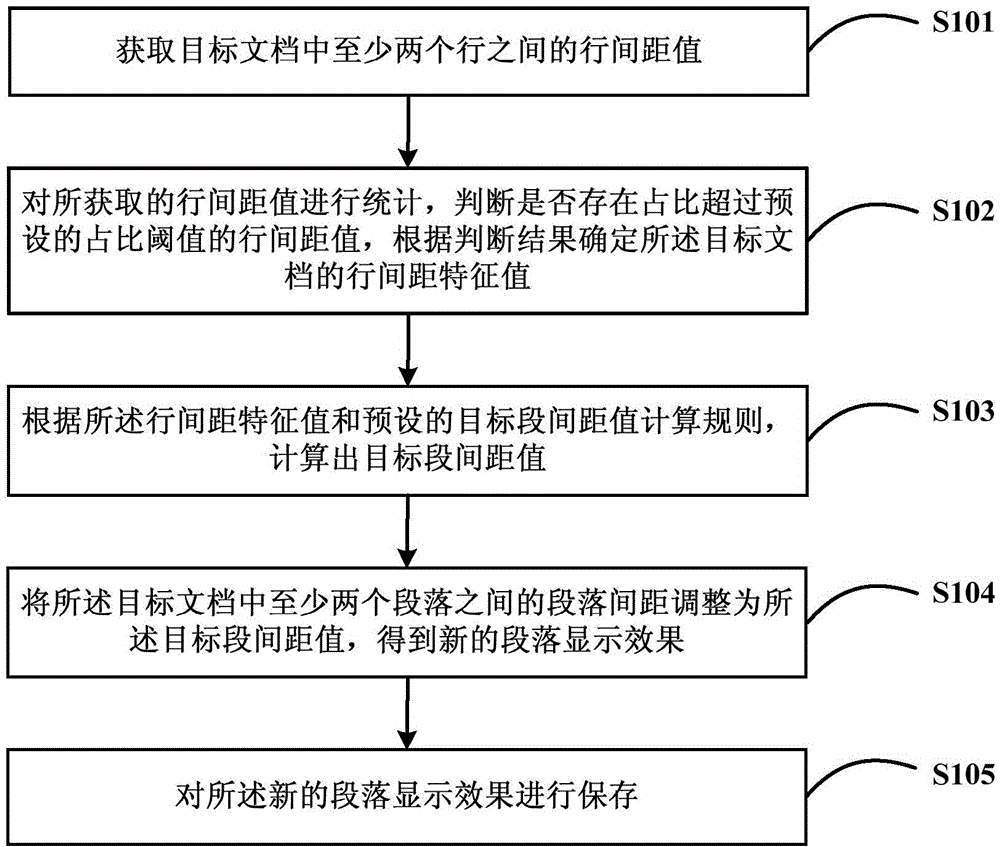

Method and device for adjusting paragraph spacing

ActiveCN105677619AOvercome cumbersome operationsImprove efficiencyNatural language data processingSpecial data processing applicationsDocument preparationParagraph

The embodiment of the invention discloses a method and device for adjusting paragraph spacing.The method for adjusting paragraph spacing comprises following steps: obtaining line spacing value between at least two lines of an object document; counting obtained line spacing value, judging whether the proportion exceeds the line spacing value of the pre-set proportion threshold, and determining the line spacing value with the proportion exceeding the pre-set proportion threshold when the determination result is yes; calculating the object segment spacing value according to the line spacing feature value and a calculation rule for the pre-set object segment spacing value; and adjusting the paragraph spacing between at least two paragraphs in the object document as the object paragraph spacing value in order to obtain a new paragraph display effect. Therefore, the method and device for adjusting paragraph spacing have following beneficial effects: paragraph spacing between two paragraphs with many margins of the document can be automatically adjusted to the proper paragraph spacing suitable for a user to read; the deficiency of complicated operation induced by manual operation of the user is overcome; and higher efficiency is obtained.

Owner:ZHUHAI KINGSOFT OFFICE SOFTWARE +2

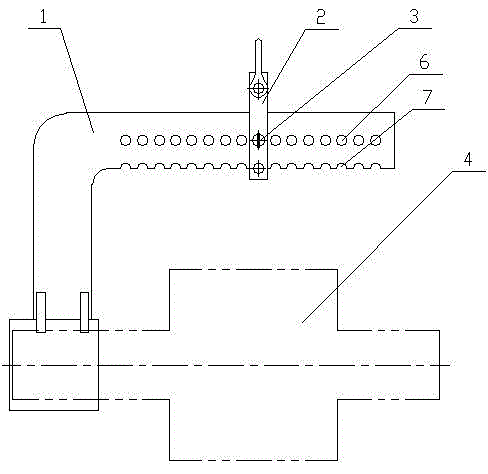

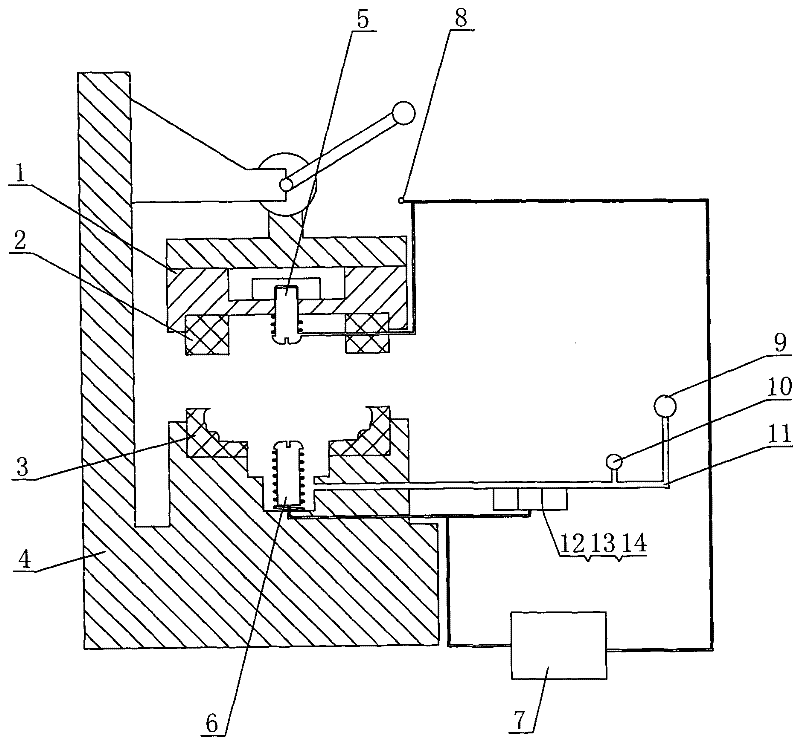

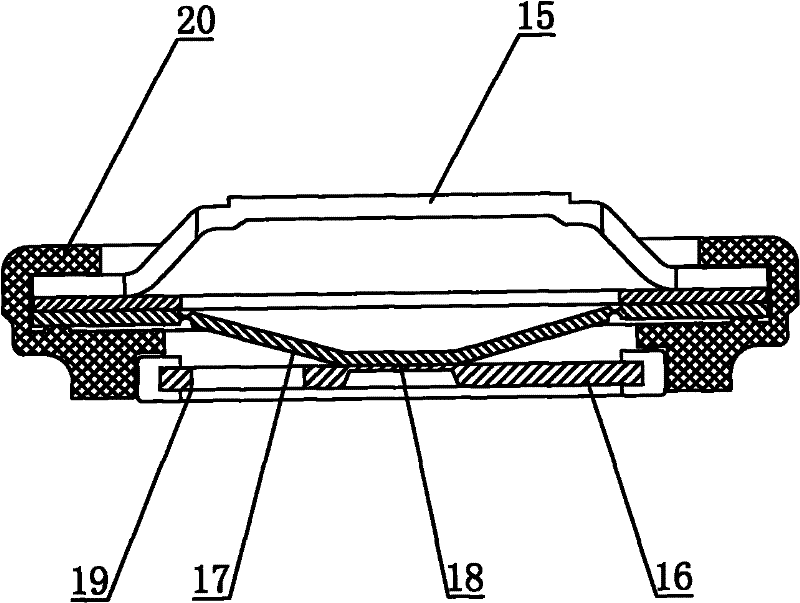

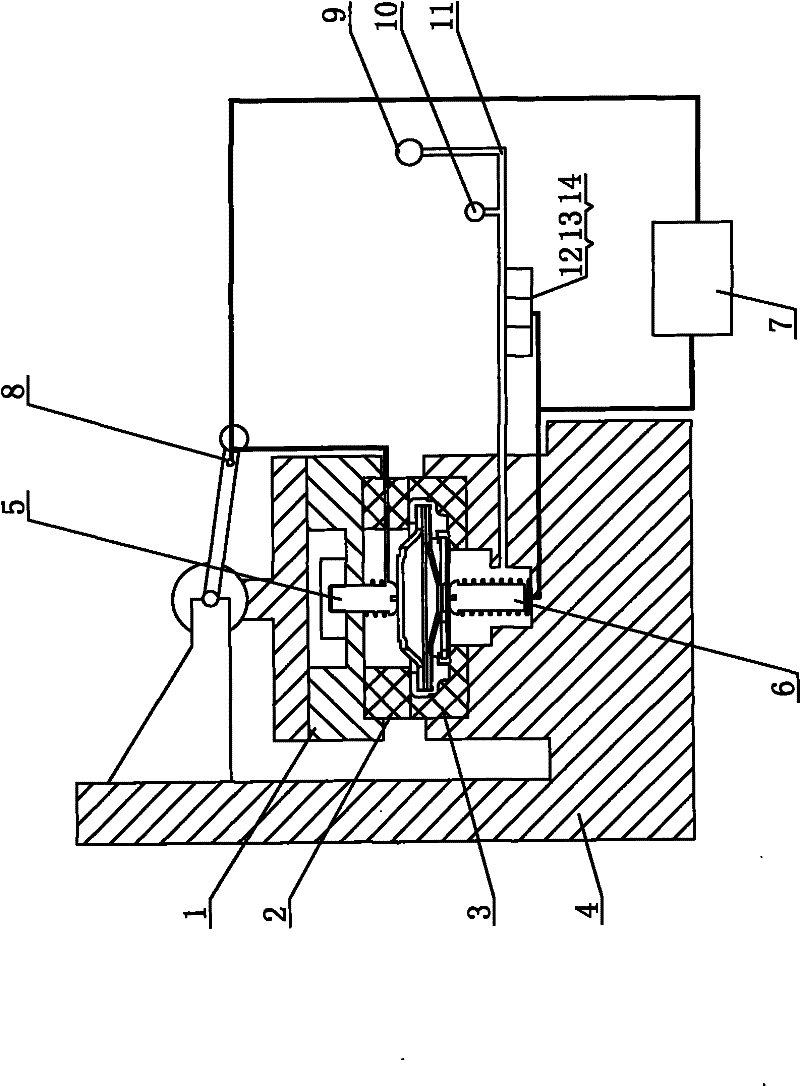

Precise testing device of safety valve of cylindrical lithium-ion battery

InactiveCN101793586BStable detectionLess consumablesMeasurement of fluid loss/gain rateControl systemSolenoid valve

The invention relates to a precise testing device of a safety valve of a cylindrical lithium-ion battery, which comprises a press seat, a base and a control system. An elastic contact is respectively arranged in the cavities of the press seat and the base, the two elastic contacts are both connected with the control system to test the internal resistance and the welding point breaking pressure ofa safety valve; the hollow cavity of the base is communicated with an air intake pipe, a pressure sensor, a solenoid valve, a progressive switch, a pressure gauge and a pressure-stabilizing air source are arranged on the air intake pipe, wherein the pressure sensor, the solenoid valve and the progressive switch are connected with the control system to test the turning pressure and the bursting pressure of the safety valve; and a press sensor connected with the control system is arranged on the elastic contact of the press seat or the base for control. The invention realizes the testing of multiple indicators with one safety valve at one step, achieves convenient, rapid and high-precision testing, avoids the error caused by manual operation and the influence of the equipment sensitivity ontesting, and also has the advantages of small testing error and low material consumption for testing.

Owner:TAIXING ZHENGXING ELECTRON

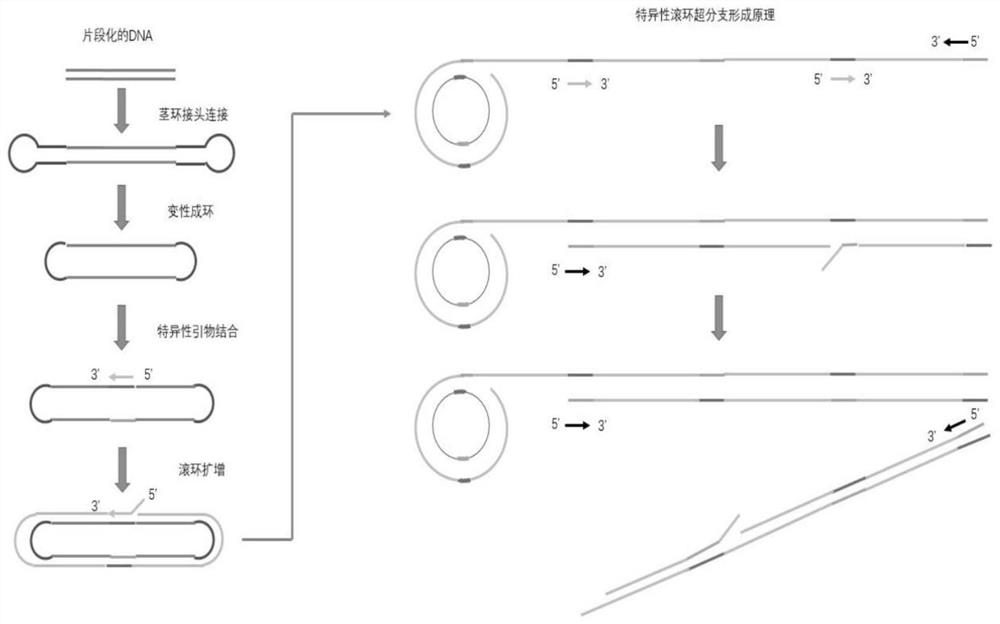

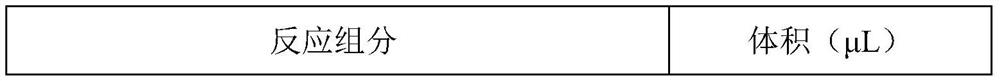

Targeted enrichment method for trace DNA and use thereof

InactiveCN113549675AImprove capture efficiencyEasy to operateMicrobiological testing/measurementTarget enrichmentGene trapping

The invention relates to the technical field of sequencing, in particular to a targeted enrichment method for trace DNA and use thereof. The targeted enrichment method for trace DNA comprises the following steps: S1, adding an A tail to a tail end of fragmented genome DNA; S2, connecting the fragmented DNA added with the A tail obtained in step S1 with a stem-loop joint to form annular DNA; S3, carrying out a rolling circle amplification enrichment on the annular DNA obtained in step S2 by adopting a target primer; and S4, constructing a sequencing library. The capture method can be applied to trace DNA, has high targeted enrichment efficiency and is simple and convenient to operate, and can be used for target gene capture and low-frequency mutation detection.

Owner:徐州海纳生物科技有限公司

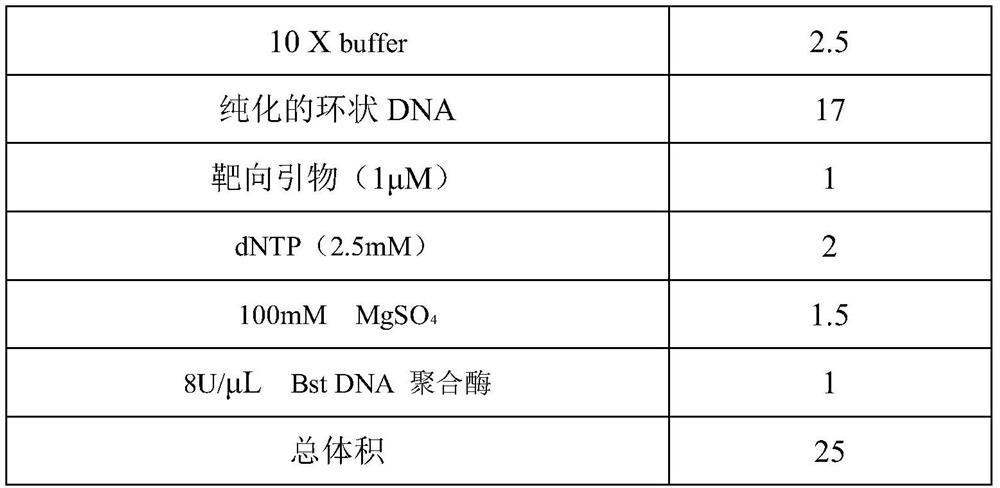

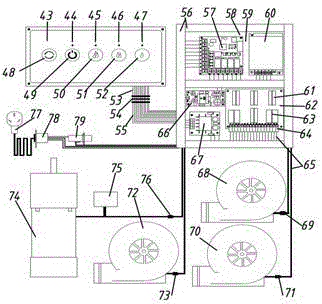

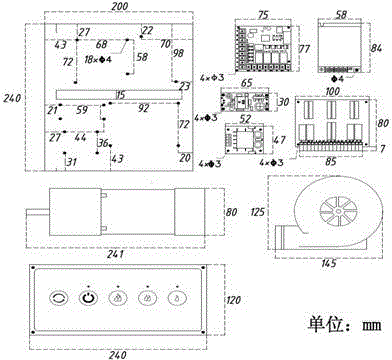

Integrated control circuit of biomass cooking range

ActiveCN104566490AOvercome cumbersome operationsLow energy consumptionDomestic stoves or rangesLighting and heating apparatusBiomassScram

The invention discloses an integrated control circuit of a biomass cooking range. The integrated control circuit consists of a power supply device unit, a man-machine interface unit, a control unit and a load unit; the power supply device unit consists of a power supply input part, a bare board power supply (5) and a switch power supply (33); the man-machine interface unit is a switch panel (12), and consists of a scram button (17), a start / stop button (18), a high flame button (19), a medium flame button (20), a low flame button (21), a power indicator lamp (13), a high flame indicator lamp (14), a medium flame indicator lamp (15) and a low flame indicator lamp (16); the control unit consists of a programmable controller (7), a relay peripheral circuit board (39) and a pressure regulating module (25); the load unit consist of a fan set and a feeding motor (36). According to the integrated control circuit disclosed by the invention, the defects of complicated operation, high energy consumption, high fault rate and the like of a discrete component circuit of the traditional biomass cooking range are overcome, and the good effects of being low in energy consumption, simple in structure, convenient to use, safe and reliable are achieved.

Owner:安乡龙威新能源科技开发有限责任公司

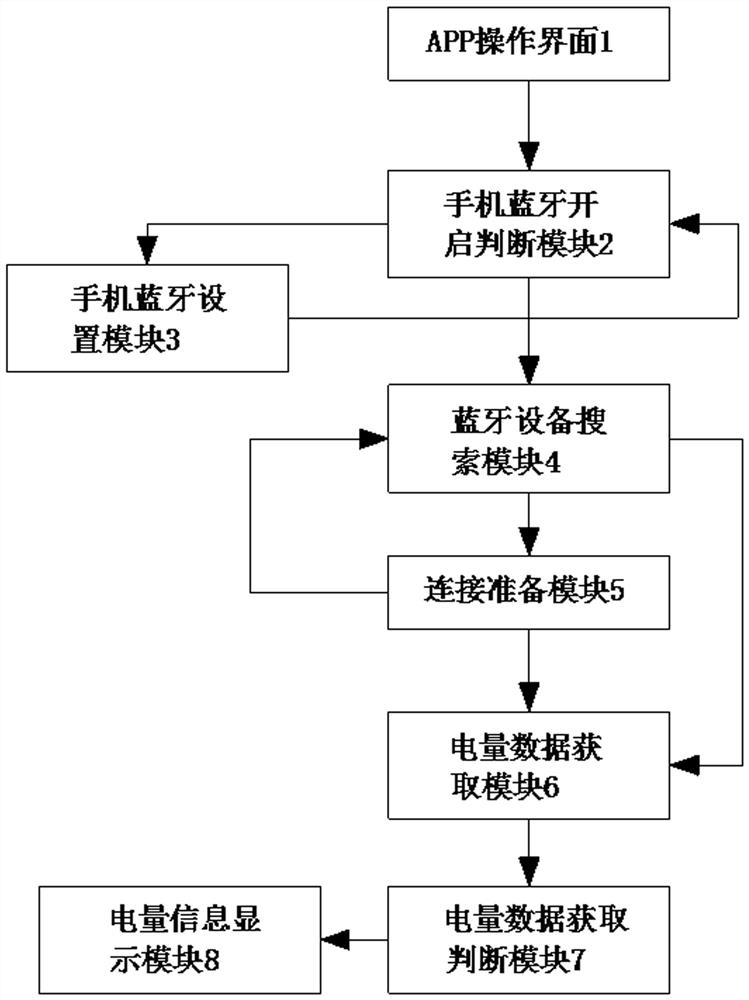

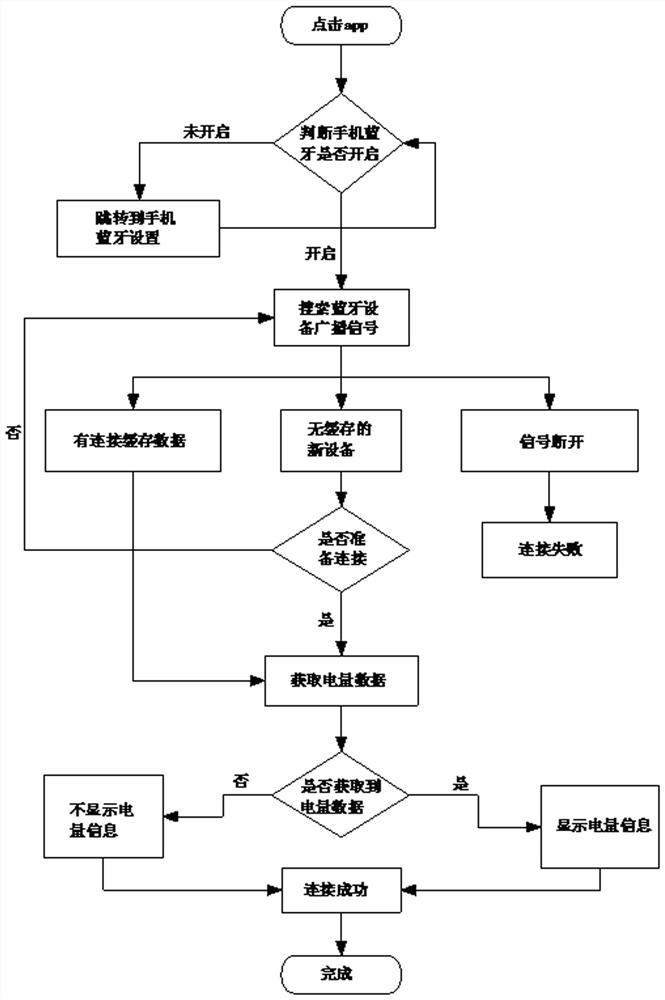

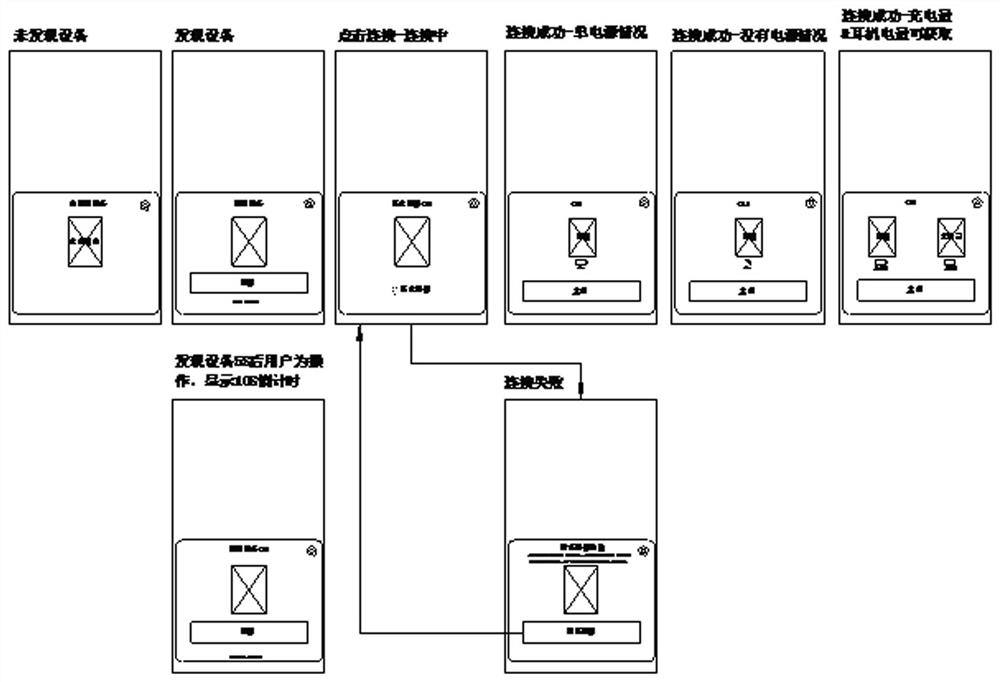

Bluetooth connection convenient application system

PendingCN112533181AOvercome cumbersome operationsConnection managementDevices with bluetooth interfacesData acquisitionData acquisition module

The invention discloses a Bluetooth connection convenient application system, which comprises an APP operation interface, a mobile phone Bluetooth opening judgment module, a mobile phone Bluetooth equipment search module, a mobile phone Bluetooth setting module, a connection preparation module, an electric quantity data acquisition module and an electric quantity data acquisition judgment module,wherein the APP operation interface is connected with the mobile phone Bluetooth opening judgment module; the mobile phone Bluetooth starting judgment module is connected with the mobile phone Bluetooth setting module, and the mobile phone Bluetooth starting judgment module is connected with the mobile phone Bluetooth equipment search module. The invention discloses the Bluetooth connection convenient application system, wherein a connection button is clicked on a mobile phone interface, and Bluetooth connection can be realized by clicking a completion button after successful connection.

Owner:深圳市三嘉立信科技有限公司

A treatment system and treatment method for industrial wastewater containing fluorine and nitrate nitrogen

ActiveCN108249707BReduce volumeSmall footprintWater contaminantsTreatment with anaerobic digestion processesIndustrial waste waterReverse osmosis

The invention discloses a treatment system and treatment method of fluorine-containing and nitrate nitrogen-containing industrial waste water, which belongs to the technical field of waste water treatment. The treatment system and method are used for firstly separating ordinary waste water into fluorine-containing and nitrate nitrogen-containing concentrated water and clean water by virtue of a hyperfiltration and reverse osmosis system, then mixing the fluorine-containing and nitrate nitrogen-containing concentrated water and strong-acidic waste water, guide the mixed water into a denitrification pool, and discharge the water up to standard after the fluorine removal by virtue of denitrification nitrogen removal and a chemical precipitation method. By adopting the method disclosed by theinvention, the biochemical and chemical precipitated waste water amount can be effectively reduced, the floor occupation area of a waste water pool can be reduced, and the fixed investment cost is decreased; and in addition, an alkali precipitation unit is arranged behind a biochemical reaction unit, so that the acid consumption and alkali increasing effect of the denitrification reaction can be sufficiently utilized, the cost of a great amount of alkali for removing fluorine and a great amount of acid for the denitrificaiton process in the traditional process is decreased, and the treatment system and the treatment method are suitable for the industrialized application.

Owner:NANJING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com