Method for producing benzaldehyde by oxidizing dibenzyl ether by air

A technology for oxidizing dibenzyl ether and dibenzyl ether, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of limiting the use range of benzaldehyde, high production cost, cumbersome operation, etc., and achieve production The effects of industrialization, quality assurance, and overcoming cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

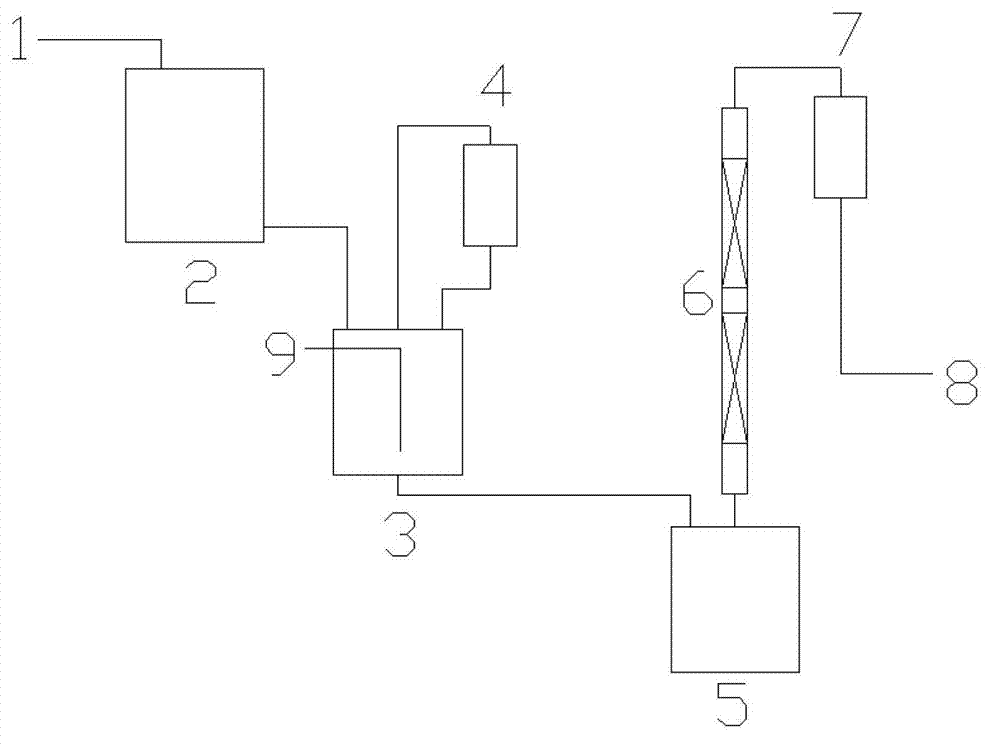

[0019] Such as figure 1 Shown is a process flow diagram of the present invention, a kind of method that air oxidation dibenzyl ether produces benzaldehyde, and operation steps are as follows:

[0020] (1) Dibenzyl ether head tank 2 prepares raw materials, and the dibenzyl ether produced in the benzyl alcohol section is pumped into the dibenzyl ether head tank 2 through the feed port 1 of the dibenzyl ether head tank 2, and the liquid level reaches the dibenzyl ether head tank 2 accumulatively Pilot production of benzaldehyde with a height of more than 60%;

[0021] (2) Feed the electric heating reactor 3, feed from the dibenzyl ether elevated tank 2 to the electric heating reactor 3 until the liquid level reaches 80% of the height of the electric heating reactor 3, turn on the electric heating reactor 3 to heat up; electric heating Reactor 3 is provided with reactor condenser 4;

[0022] (3) Remove water before the reaction, first steam the water in the dibenzyl ether, relea...

Embodiment 2

[0028] Such as figure 1 Shown is a process flow diagram of the present invention, a kind of method that air oxidation dibenzyl ether produces benzaldehyde, and operation steps are as follows:

[0029] (1) Dibenzyl ether head tank 2 prepares raw materials, and the dibenzyl ether produced in the benzyl alcohol section is pumped into the dibenzyl ether head tank 2 through the feed port 1 of the dibenzyl ether head tank 2, and the liquid level reaches the dibenzyl ether head tank 2 accumulatively Pilot production of benzaldehyde with a height of more than 60%;

[0030] (2) Feed the electric heating reactor 3, feed from the dibenzyl ether elevated tank 2 to the electric heating reactor 3 until the liquid level reaches 80% of the height of the electric heating reactor 3, turn on the electric heating reactor 3 to heat up; electric heating Reactor 3 is provided with reactor condenser 4;

[0031] (3) Remove water before the reaction, first steam the water in the dibenzyl ether, relea...

Embodiment 3

[0037] Such as figure 1 Shown is a process flow diagram of the present invention, a kind of method that air oxidation dibenzyl ether produces benzaldehyde, and operation steps are as follows:

[0038] (1) Dibenzyl ether head tank 2 prepares raw materials, and the dibenzyl ether produced in the benzyl alcohol section is pumped into the dibenzyl ether head tank 2 through the feed port 1 of the dibenzyl ether head tank 2, and the liquid level reaches the dibenzyl ether head tank 2 accumulatively Pilot production of benzaldehyde with a height of more than 60%;

[0039] (2) Feed the electric heating reactor 3, feed from the dibenzyl ether elevated tank 2 to the electric heating reactor 3 until the liquid level reaches 80% of the height of the electric heating reactor 3, turn on the electric heating reactor 3 to heat up; electric heating Reactor 3 is provided with reactor condenser 4;

[0040] (3) Remove water before the reaction, first steam the water in the dibenzyl ether, relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com