Crack prefabricating method of fragile ceramics, and crack prefabricating support and application thereof

A technology of prefabricated cracks and ceramics, which is applied in the preparation, sampling, and measuring devices of test samples, can solve the problems of long time consumption of prefabricated cracks and general pass rate of prefabricated cracks, and achieves high pass rate, shortened process time and process time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

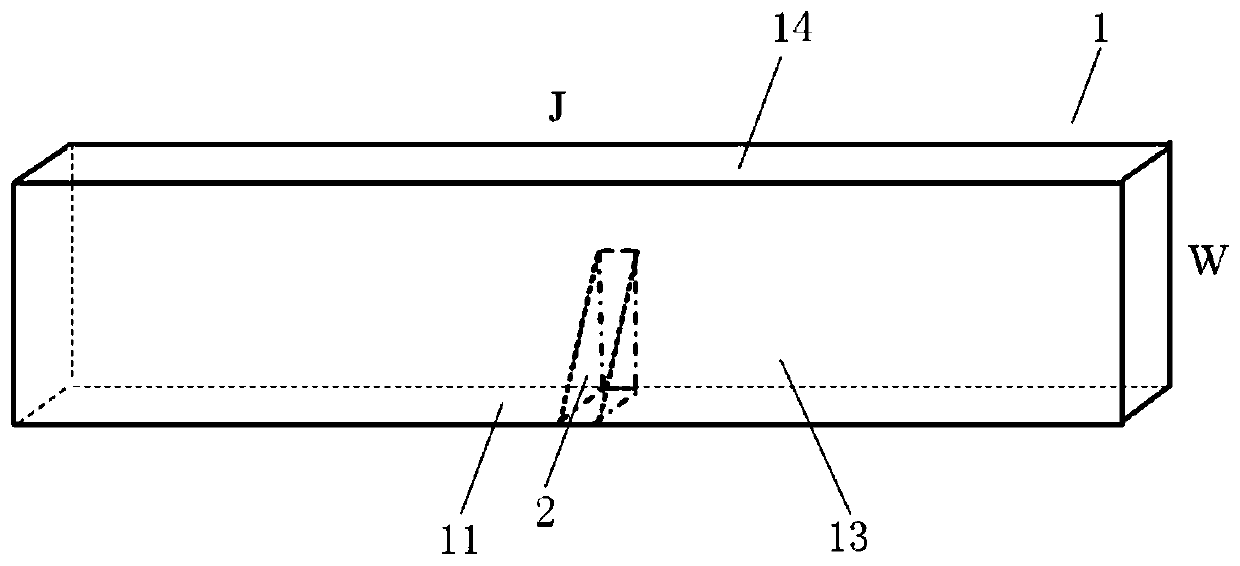

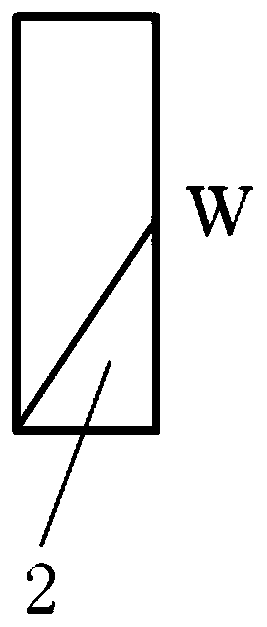

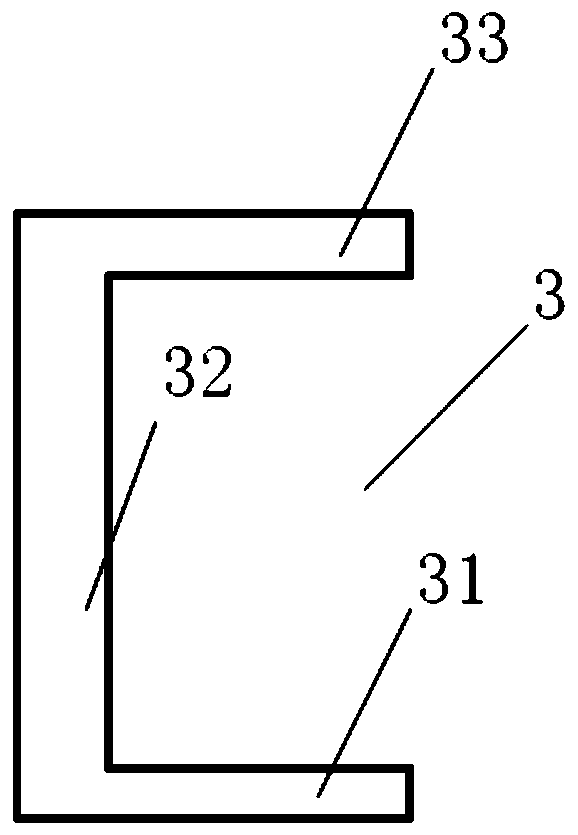

[0077] In the embodiment of the present invention, alumina ceramics, which are brittle and difficult to pre-crack, are taken as an example to pre-crack, and check the length of the crack and the morphology of the fracture. Figure 4 It is the kerf photo of the test piece in the present embodiment; Figure 5 It is the crack photo of the test piece in this embodiment.

[0078] The process parameters, process time and the length of the pre-cracks are shown in Table 1 below by pre-cracking the same batch of alumina ceramics of the same specification.

[0079] Process parameter, process time and the length of prefabricated crack in the embodiment of table 1

[0080]

[0081]

[0082]As can be seen from the data in Table 1 above, the test pieces described in Examples 1-9 are prefabricated with cracks according to the process parameters in Table 1, and the process time is short, with the shortest process time being 149s, less than 3 minutes; the leanest process parameter contr...

Embodiment 10-12

[0084] The materials of brittle ceramics were respectively adjusted to steatite porcelain, magnesium oxide ceramics and reaction sintered SiC ceramics, and the cracks were prefabricated according to the steps in Example 1. The length of the prefabricated cracks falls within 0.35-0.6 times of the width of the test piece, that is, the length of the prefabricated cracks is controlled, and the process time of the prefabricated cracks is short.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com