Balance hanger for motor rotor

A technology for balancing spreaders and motor rotors, which is applied in the direction of load hanging components, transportation and packaging, etc., which can solve the problems that the rotor balance cannot be fine-tuned or fine-tuned, and the operation is not flexible enough, etc., so as to facilitate serialization and mass production , Reduce labor intensity, overcome the effect of cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

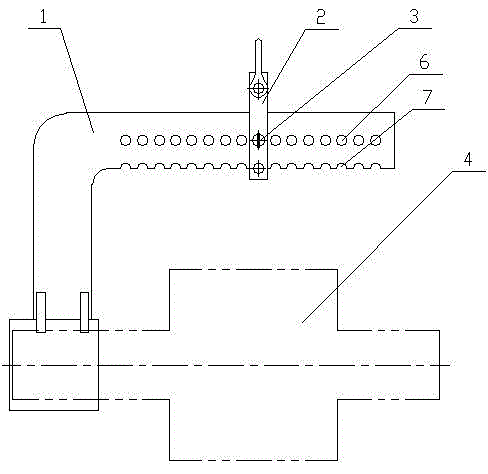

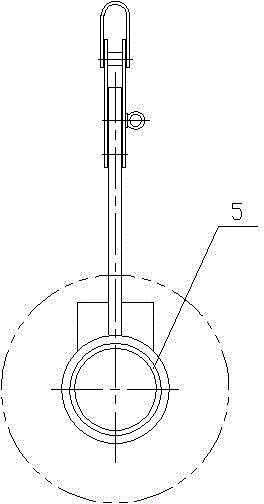

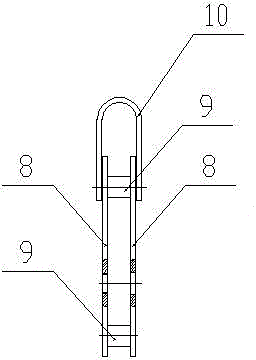

[0013] Such as figure 1 , 2 , 3, the motor rotor balance hanger of the present invention comprises an L-shaped boom 1, a suspension hook 2, pins 3 and copper sleeves 5; a row of pinholes 6 is evenly arranged on a right-angled arm of the L-shaped boom 1, L A row of semicircular grooves 7 are evenly opened on the lower edge of the right-angle arm of the L-shaped boom 1; the hook 2 is fixed on the pin hole 6 on the L-shaped boom 1 through a pin 3, and the hook 2 can be adjusted to be fixed on the L-shaped boom 1 as required. The horizontal position on the boom 1, and the position of the hook 2 is fixed by the pin 3; the hook 2 is composed of two splints 8, two pins 9, and a U-shaped hook 10, two splints 8 parallel Connected by two column pins 9 up and down, a U-shaped hook 10 is connected on two splints 8 through the upper column pin 9, and connected to the semicircular groove 7 on the lower edge of the right-angle arm of the L-shaped boom 1 through the lower column pin 9 Above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com