Load-reducing device for rolling bearing type thrust bearing for hydraulic turbine

A technology of rolling bearing and load reducing device, applied in the directions of hydroelectric power generation, engine components, machines/engines, etc., can solve the problems of high pressure oil cleanliness and tightness requirements, complicated installation and debugging, burning thrust pads, etc., to reduce wear and tear , easy to debug, to prevent the effect of burning tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

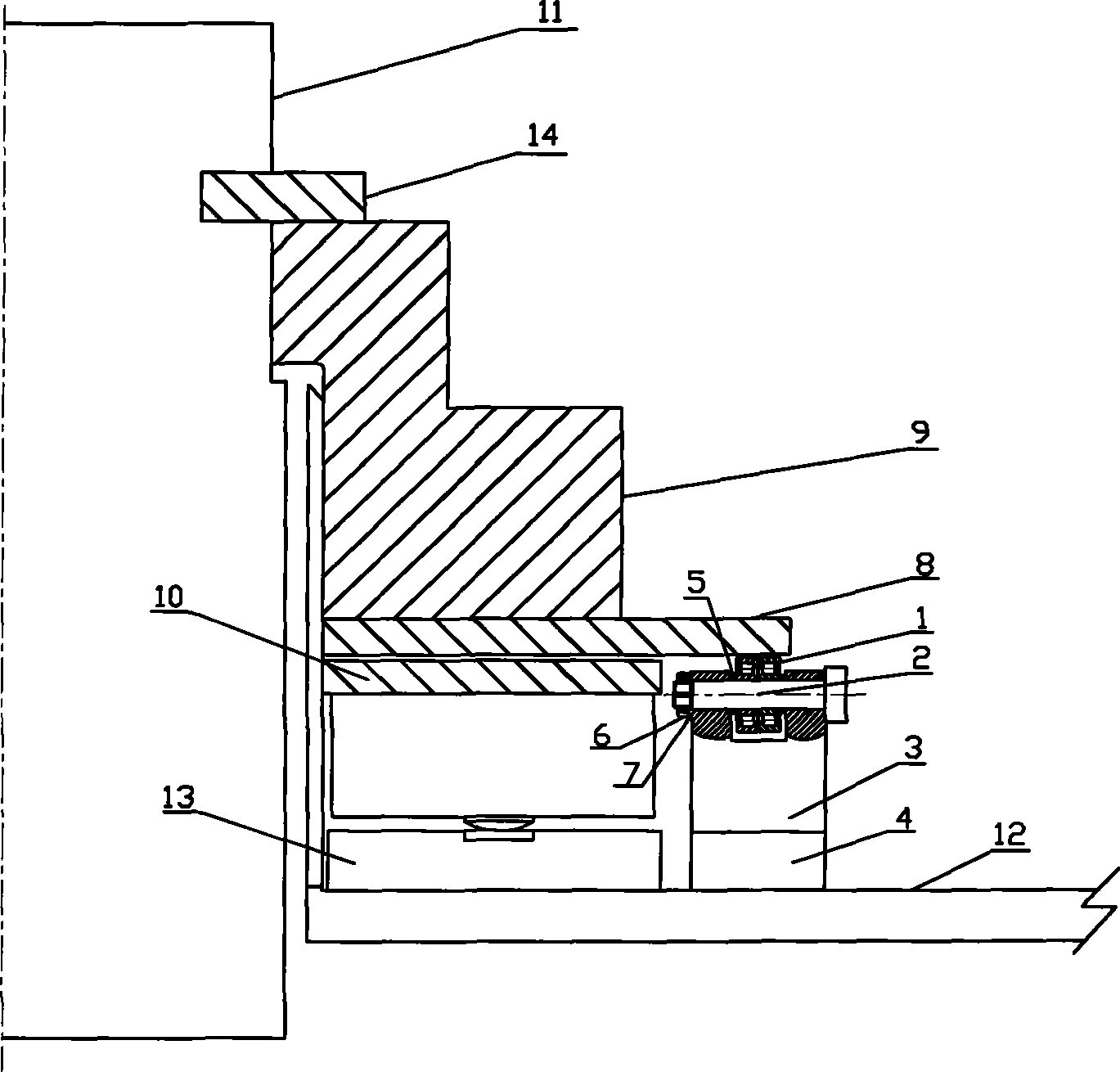

[0016] see figure 1 , the main shaft 11 is provided with a snap ring 14, and the bottom of the snap ring 14 is provided with a thrust head 9, a mirror plate 8, a thrust tile 10 and a thrust tile seat in sequence, and the thrust bearing load reduction device of the rolling bearing type hydraulic turbine is installed on the frame 12, located on The outer side of the thrust tile 10 of the water turbine, and the lower side of the mirror plate 8.

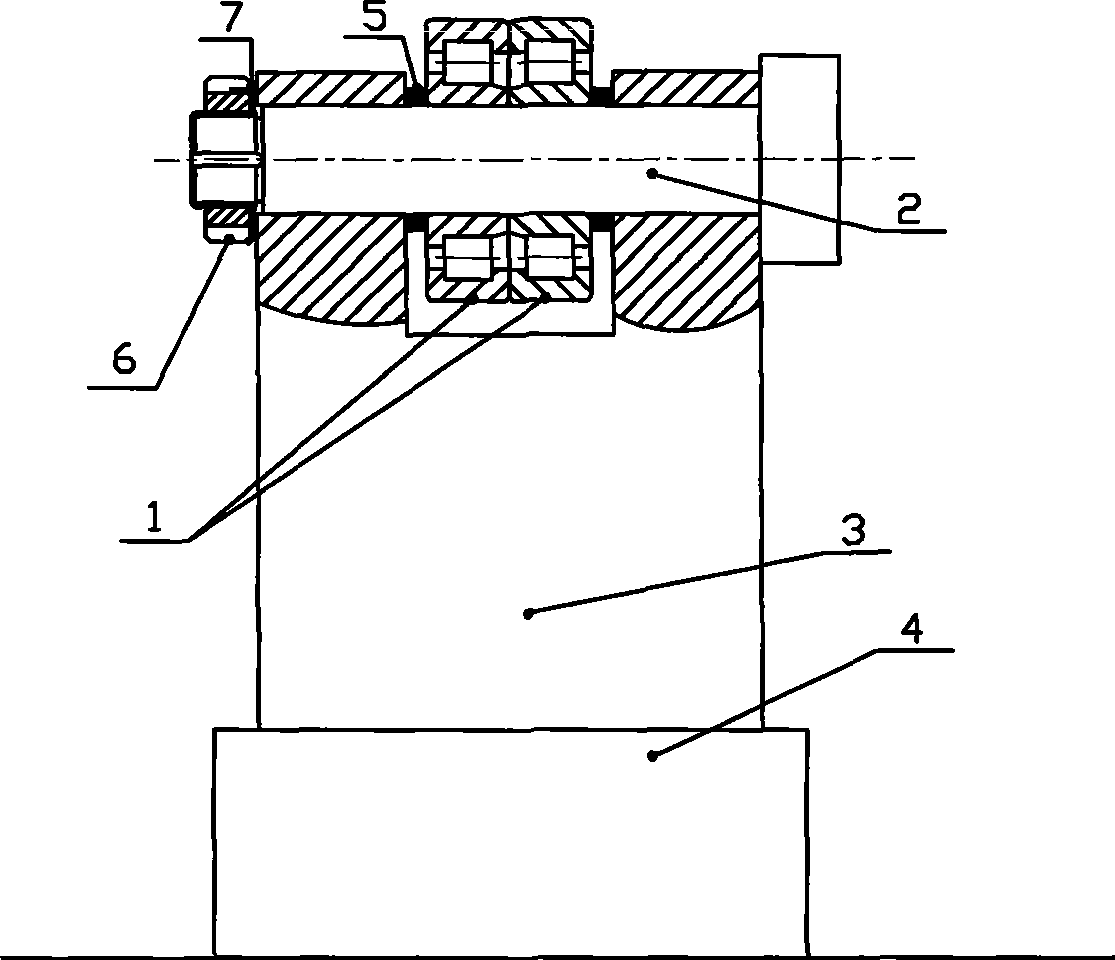

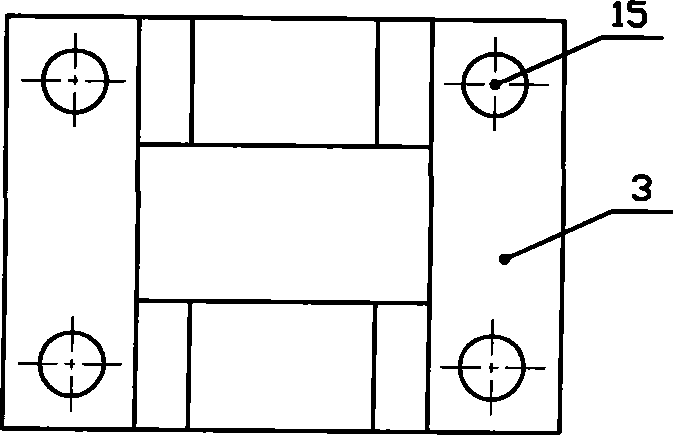

[0017] see figure 2 and figure 1 , a rolling bearing type hydraulic turbine thrust bearing load reduction device, including a support 3, a fixed shaft 2 is installed on the top of the support 3 through a round nut 6 and a stop washer 7, and a rolling bearing 1 is installed on the fixed shaft 2 through a sleeve 5, A height adjustment device 4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com