Double-source gas combined valve

A technology of dual air sources and combined valves, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of reducing the size of the whole machine, difficulty in installation, and inconvenience, etc. The effect of reducing connection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

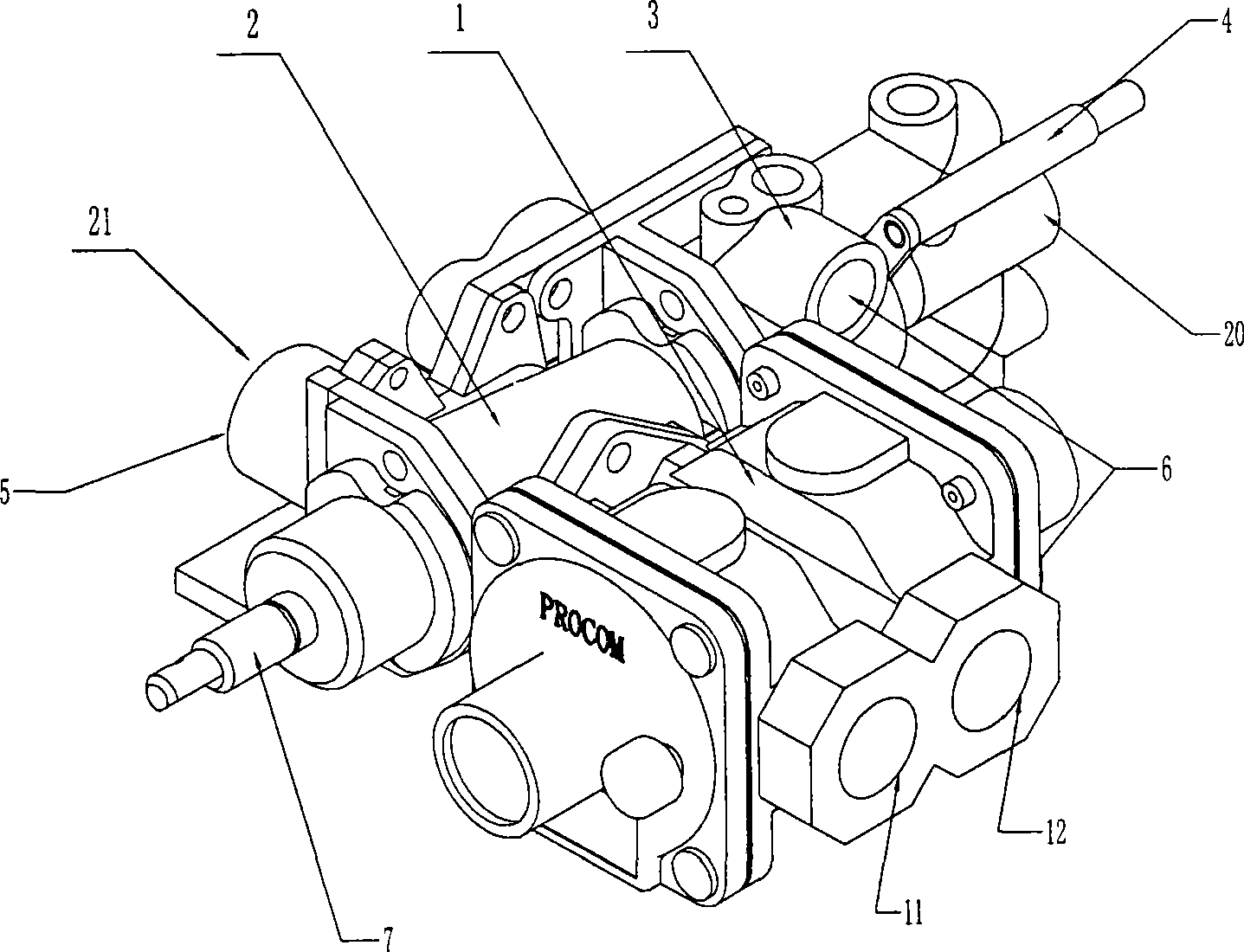

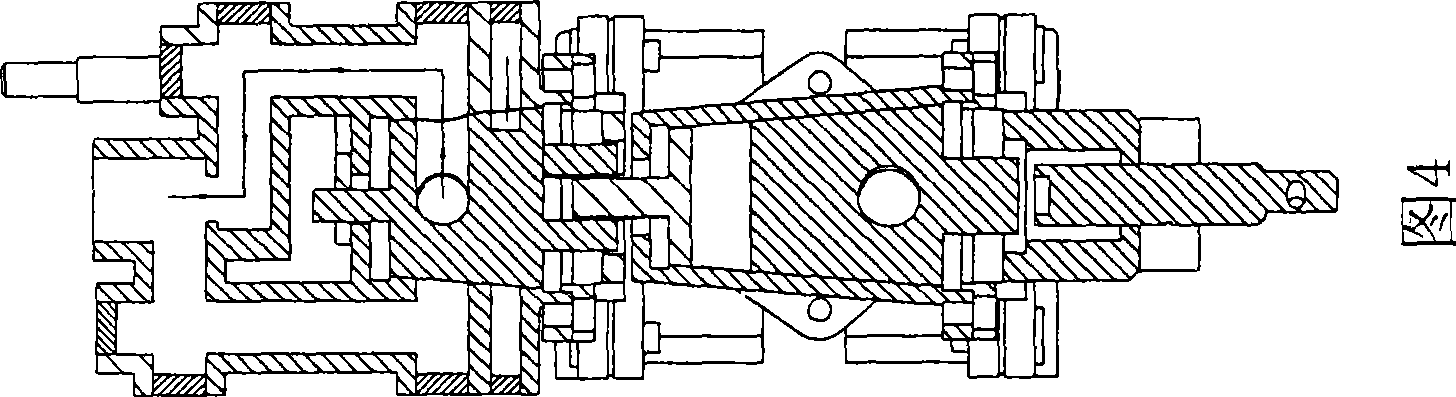

[0034] Such as figure 2 -6 shown.

[0035] A dual gas source gas combination valve, which includes a dual gas source pressure reducing valve 1 (which can be realized by using the relevant patents previously applied by the applicant), an upper conversion valve 2 (which can be realized by using the relevant patents previously applied by the applicant) ) and down conversion valve 3 (can be implemented by using the relevant patents previously applied by the applicant), damper adjusting device 4 and control valve 5 (can use common single gas sources on the market such as millivolt valves, temperature control valves, and plug valves) used control valve), such as figure 2 As shown, the dual gas source pressure reducing valve 1 is connected to the upper conversion valve 2 and communicated through the air passage, the lower conversion valve 3 is connected to the upper conversion valve 2, and the lower valve core 8 of the lower conversion valve 3 is connected to the upper valve of th...

Embodiment 2

[0041] Such as Figure 7 , 8 shown.

[0042] A dual gas source gas combination valve, which includes a dual gas source pressure reducing valve 1, an upper conversion valve 2 and a lower conversion valve 3, a damper adjustment device 4 and a control valve 5, such as Figure 7 As shown, the dual gas source pressure reducing valve 1 is connected to the upper conversion valve 2 and communicated through the air passage, the lower conversion valve 3 is connected to the upper conversion valve 2, and the lower valve core 8 of the lower conversion valve 3 is connected to the upper valve of the upper conversion valve 2. The cores 9 are connected and rotate synchronously. The upper valve core 9 of the upper conversion valve 2 is connected with a manual adjustment valve stem 7; Port 12, the high calorific value gas outlet 11 and the low calorific value gas outlet 12 of the dual gas source pressure reducing valve 1 respectively communicate with the corresponding through holes on the spoo...

Embodiment 3

[0046] Such as Figure 9 , 10 , 11.

[0047] A dual gas source gas combination valve, which includes a dual gas source pressure reducing valve 1, an upper conversion valve 2 and a lower conversion valve 3, a damper adjustment device 4 and a control valve 5, such as Figure 9 , the dual air source pressure reducing valve 1 is connected with the upper conversion valve 2 and communicated through the air passage, the lower conversion valve 3 is connected with the upper conversion valve 2, the lower valve core 8 of the lower conversion valve 3 is connected with the upper valve core 9 of the upper conversion valve 2 Connected and rotated synchronously, the upper spool 9 of the upper conversion valve 2 is connected with a manual adjustment valve stem 7; the intake end of the dual gas source pressure reducing valve 1 is provided with a high calorific value gas inlet 11 and a low calorific value gas inlet 12 , the high calorific value gas outlet 11 and the low calorific value gas out...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap