Coaxial connection type attenuator

A technology of coaxial connectors and attenuators, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of reducing the accuracy of attenuators, low rated power, and high cost, and achieve high frequency and high precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For an attenuator, for the convenience of understanding, the resistance connected in series to the signal input and output circuit is generally called a series resistance, and the resistance connected in parallel between the signal input and output circuit and the common ground is called a parallel resistance. Here, film resistors are further divided into thick film resistors and thin film resistors. Thick film resistors are made by printing thick film resistor paste on ceramic substrates and fired at high temperature; thin film resistors are made by splashing thin film resistor paste It is shot onto the ceramic substrate and sintered at high temperature; the radio frequency characteristics of the thin-film circuit are better, and it can work to tens of GHz, but the cost is more expensive.

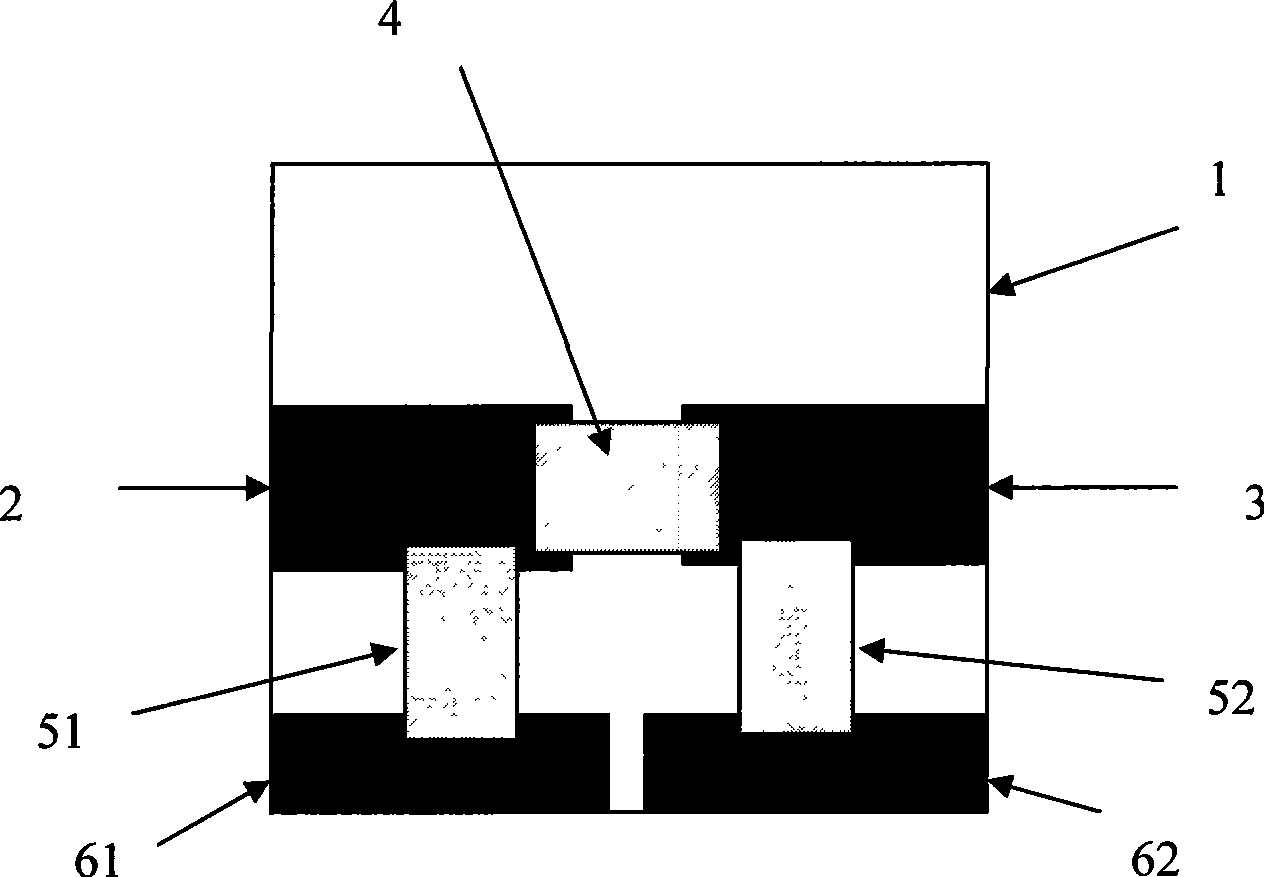

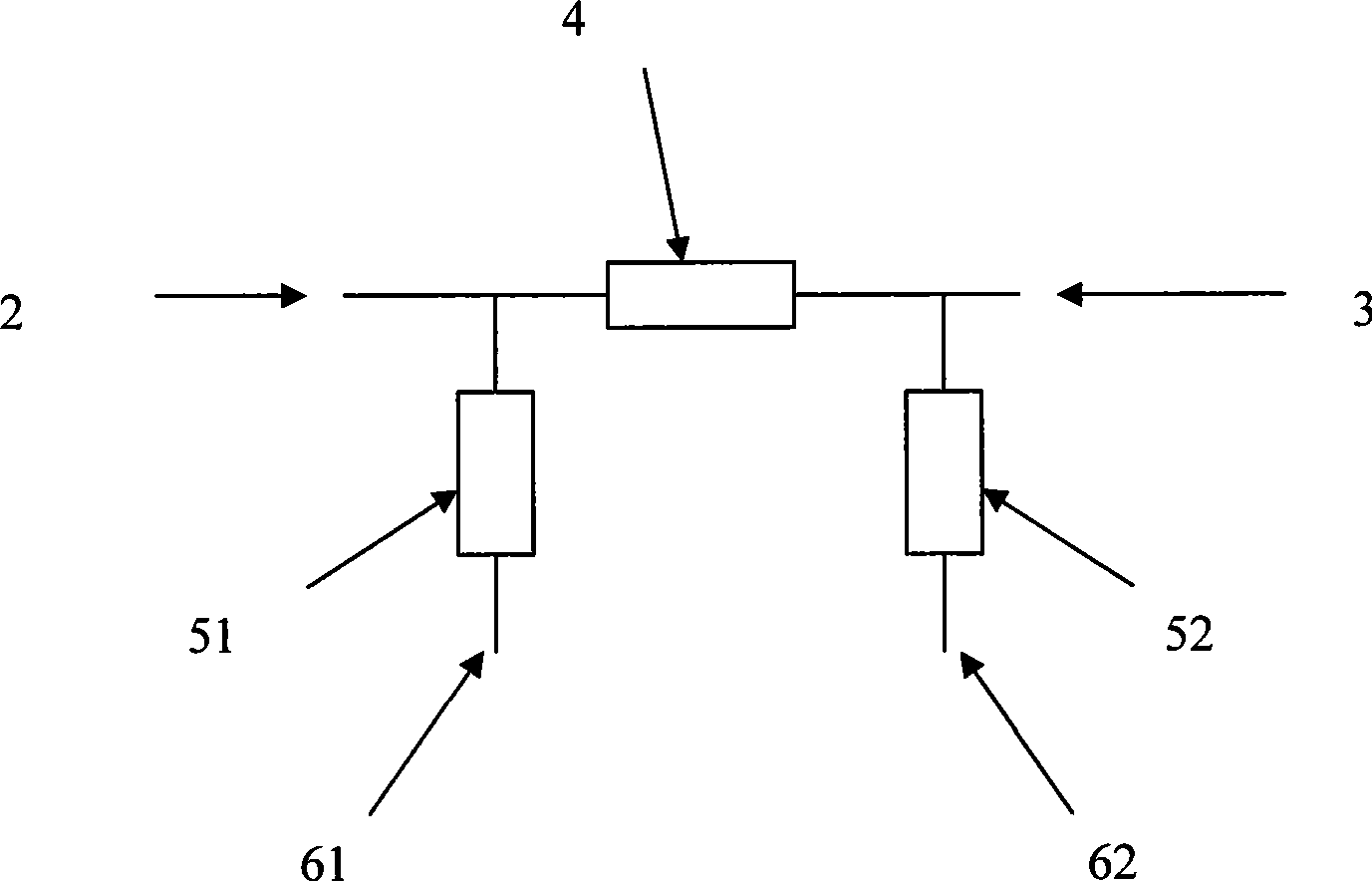

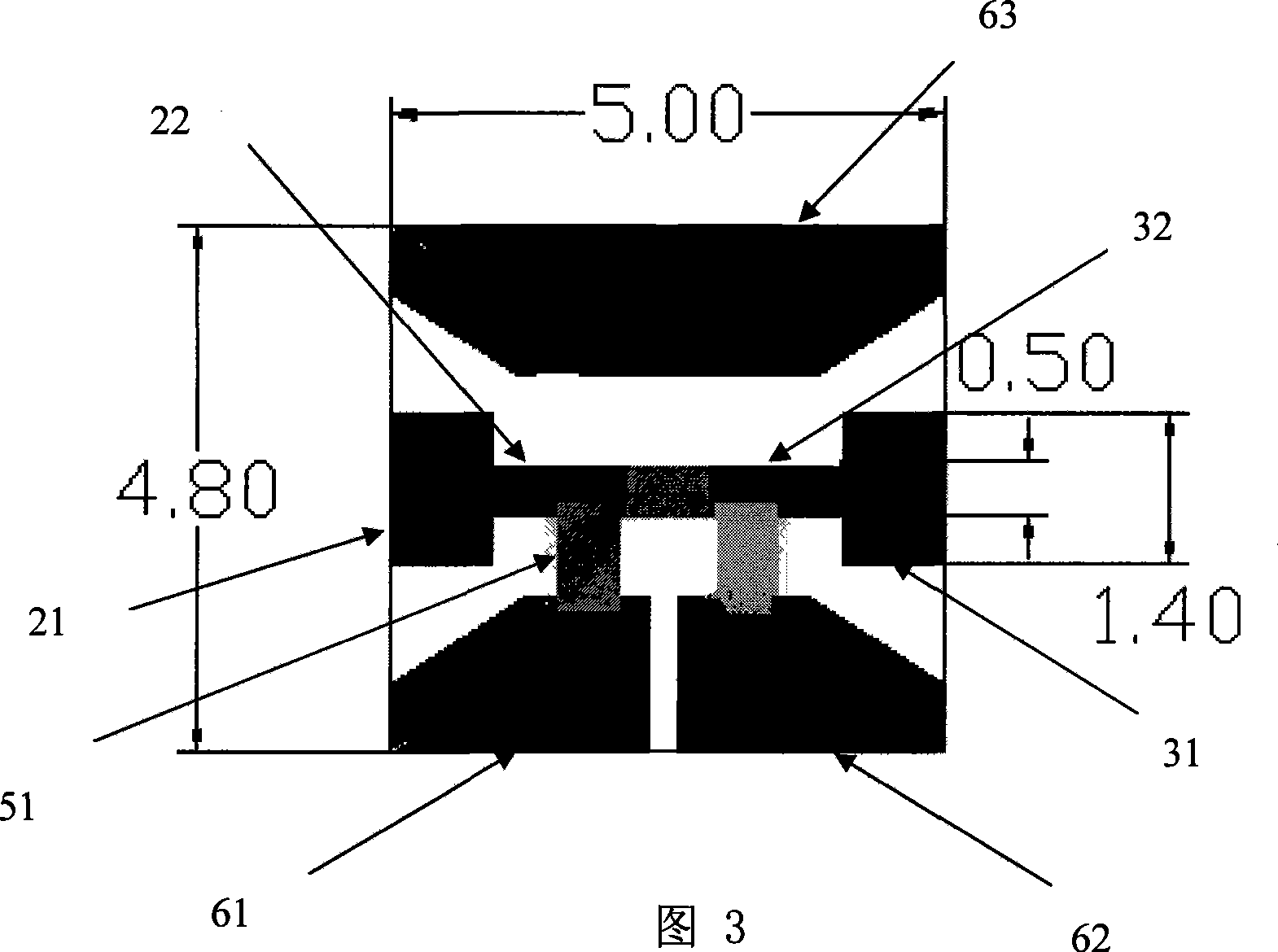

[0030] see figure 1 , which is a structural schematic diagram of the Pi (π) type network of the first embodiment of the coaxial connector type attenuator of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com