Electronic overload relay for mains-fed induction motors

A technology of rotor resistance and induction motor, which is applied in the direction of motor generator test, emergency protection circuit device, control system, etc., to achieve the effect of reducing unnecessary downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

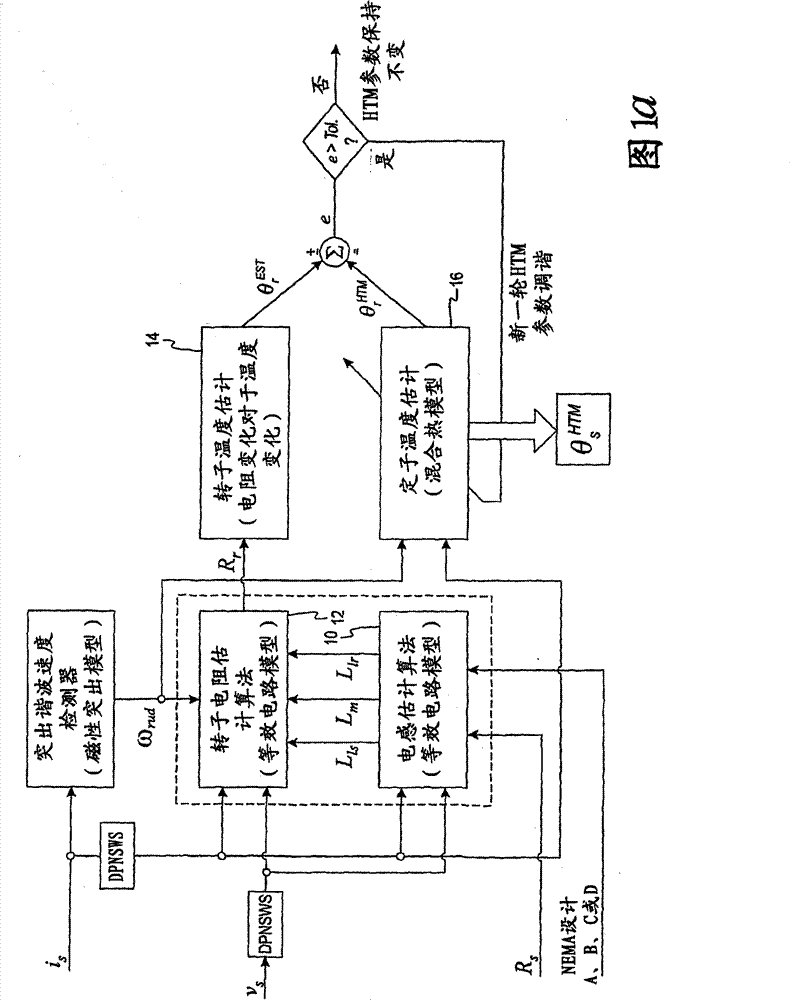

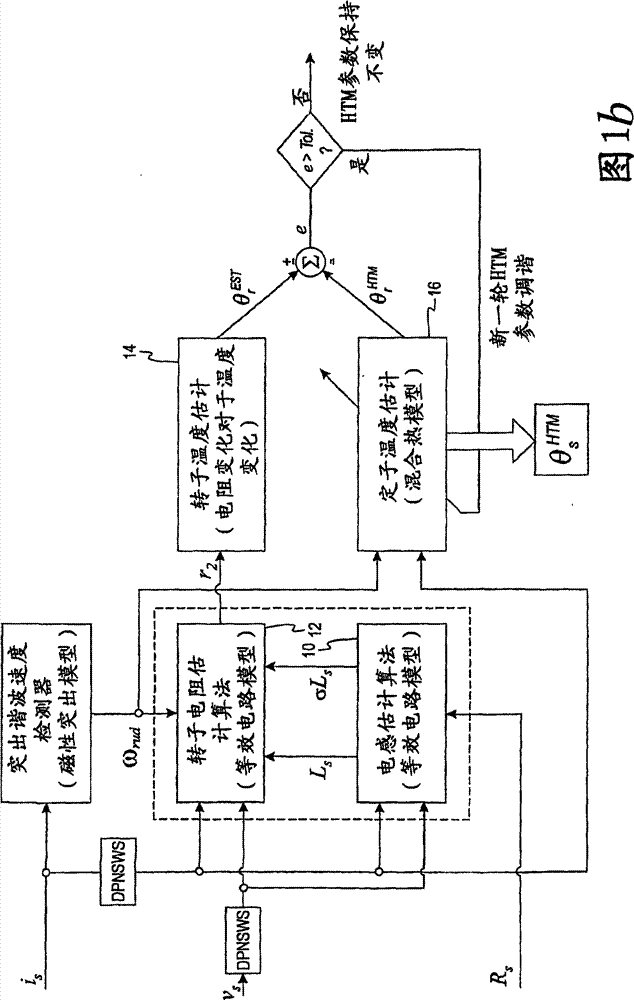

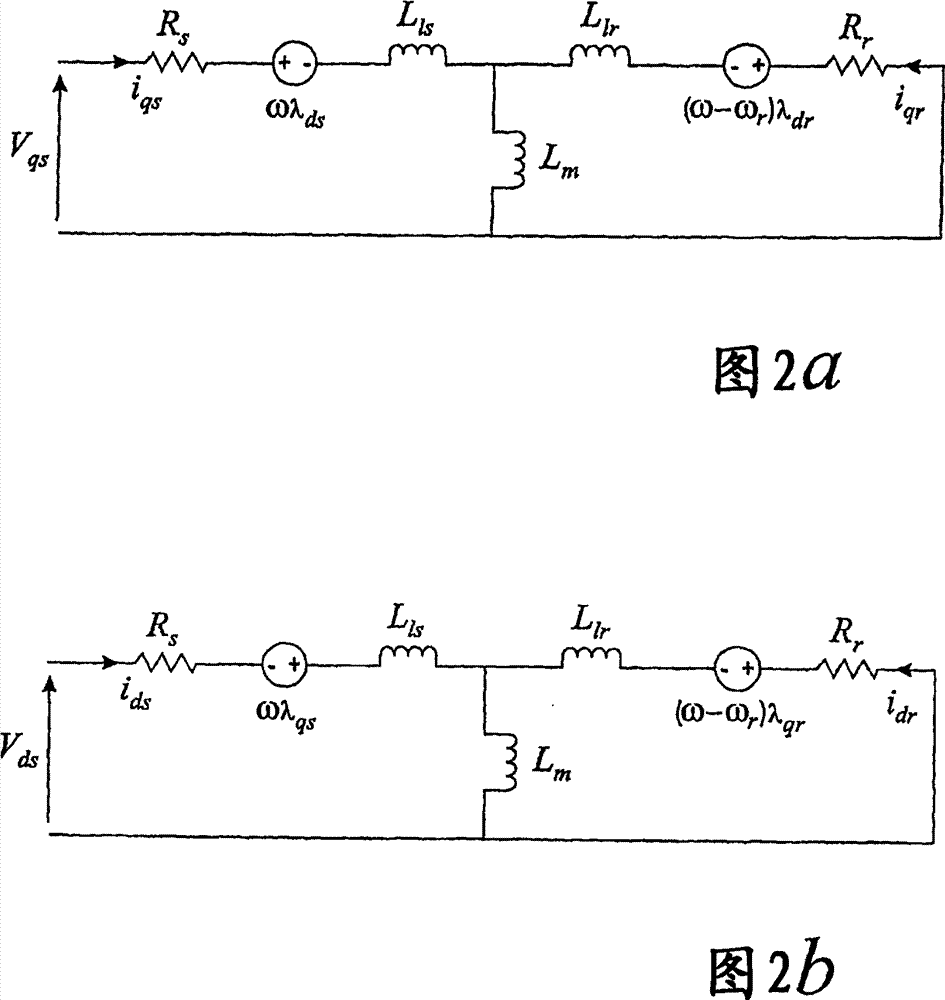

[0037] Turning now to the drawings, Figure 1 shows the overall configuration of a system for estimating stator winding temperature in an induction machine. This estimated temperature can then be used to control the tripping of electronic relays that protect the motor from overload conditions. The system includes an inductance estimator 10 , a rotor resistance estimator 12 , a rotor temperature estimator 14 , and a stator temperature estimator 16 . The on-line signals supplied to the system include signals i representing samples of the motor terminal current and voltage, respectively s and v s , the signal R representing the resistance of the stator in the motor s , and a signal representing NEMA Design A, B, C, or D of the motor. The output of the system is a signal representing the estimated stator temperature θ s HTM .

[0038] The four estimators 10 to 16 are preferably realized by a single microprocessor programmed to execute the algorithm for computing the desired e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com