Liftable floor brush of dust aspirator

A vacuum cleaner and chassis technology, which is applied in the field of liftable floor brushes of vacuum cleaners, can solve the problems of time-consuming and labor-intensive, and achieve the effect of simple overall structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

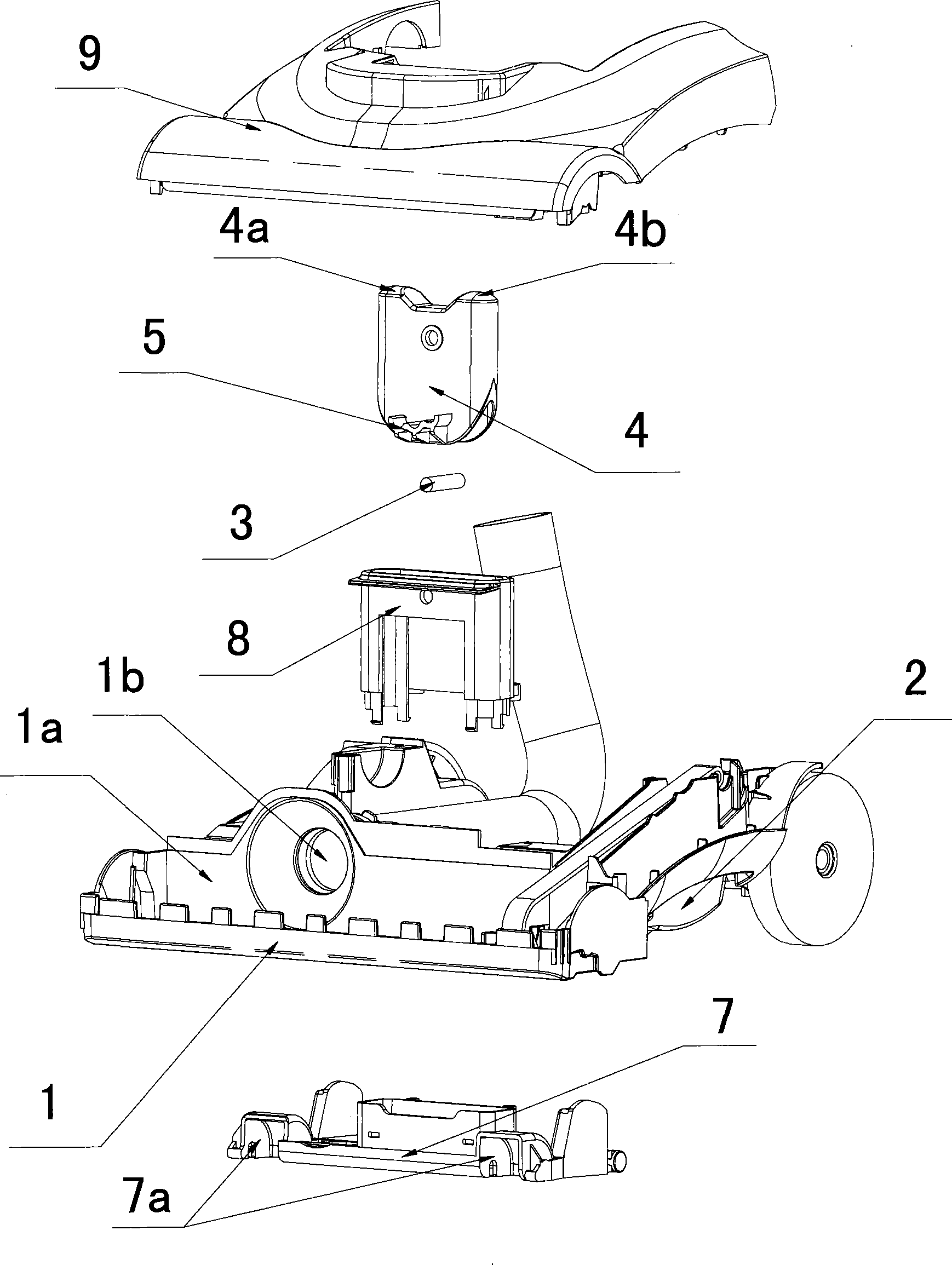

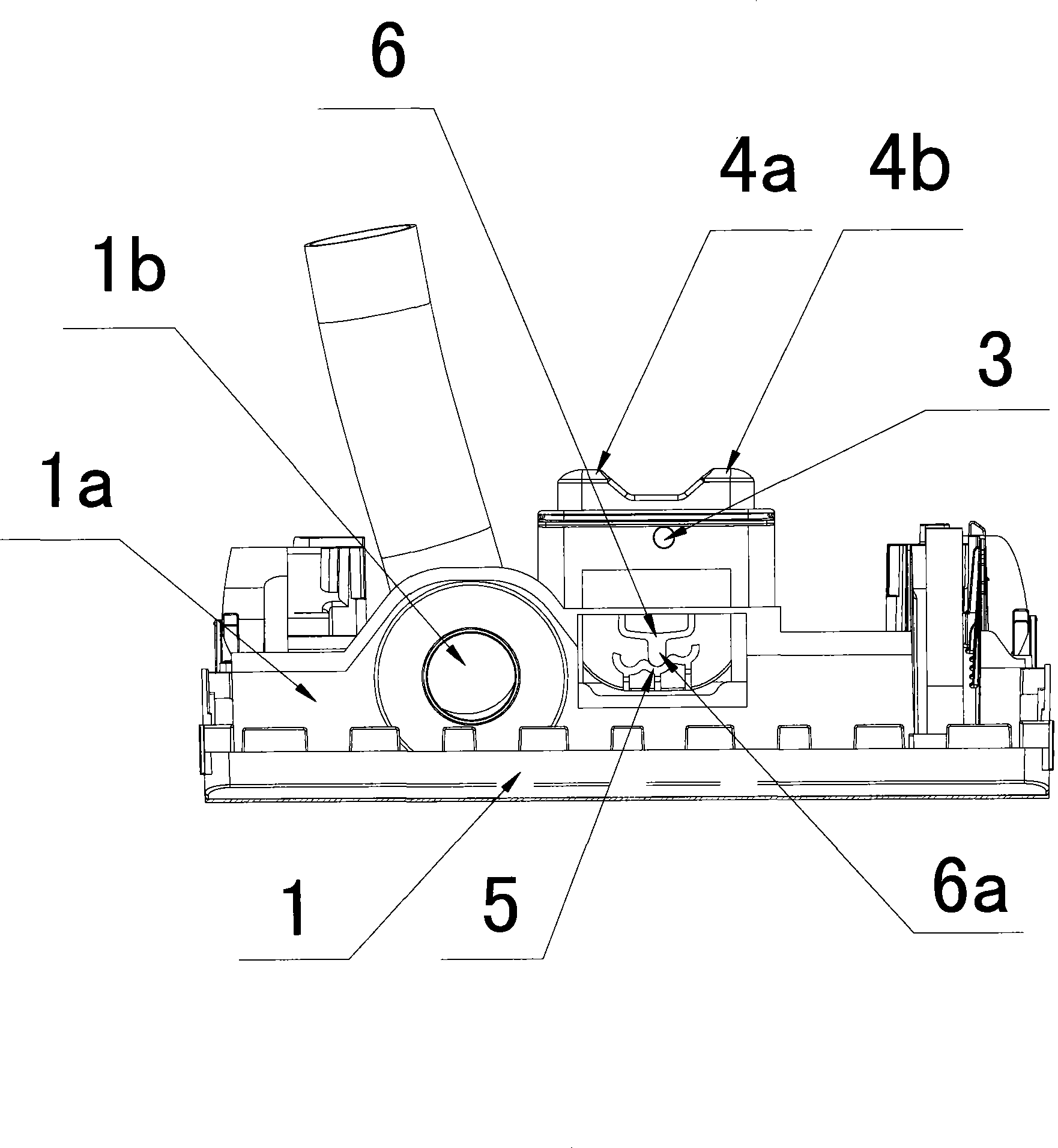

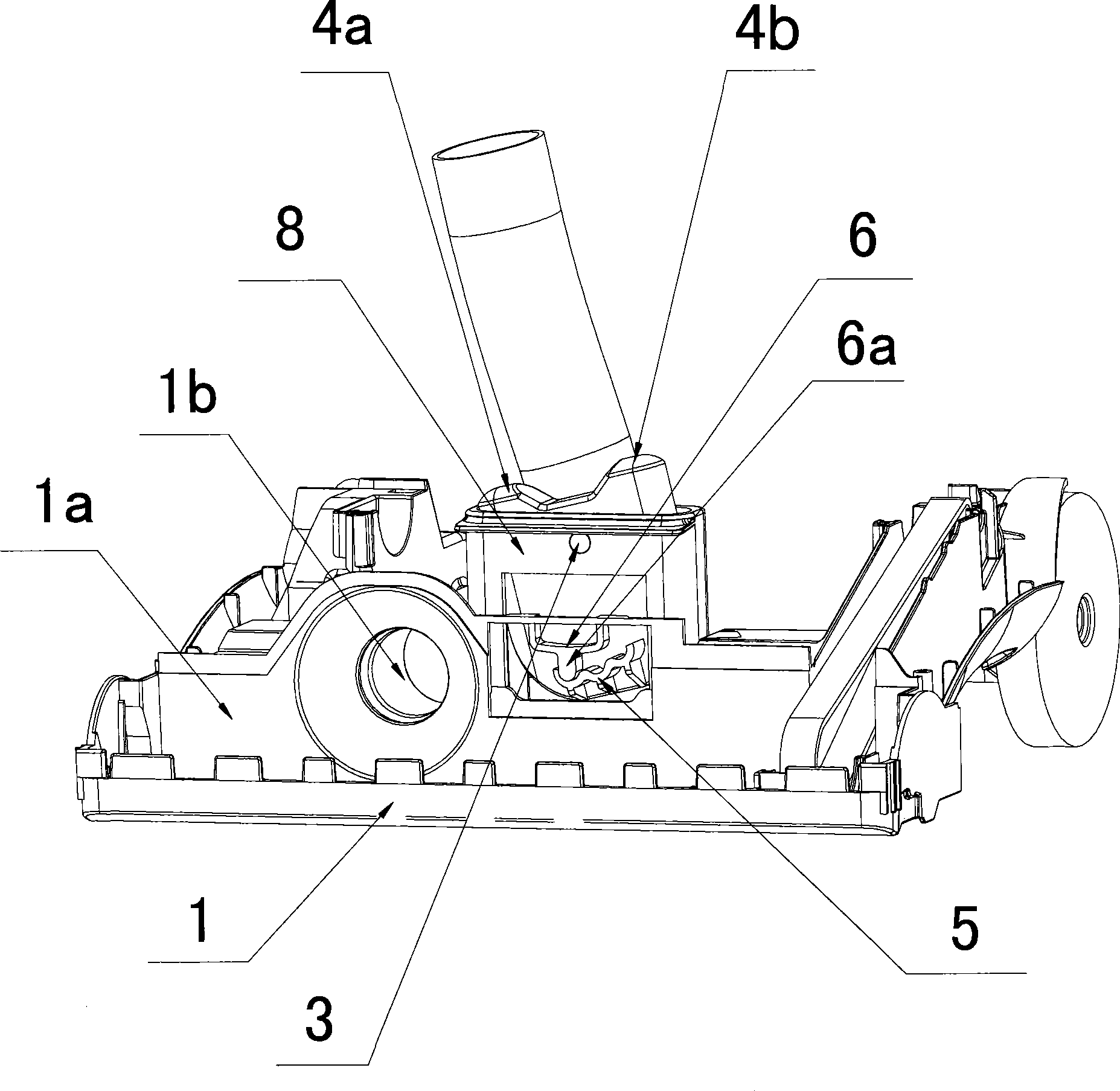

[0023] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 The specific implementation of the liftable floor brush of the vacuum cleaner of the present invention is shown, which includes a suction nozzle chassis 1 with a floor brush chamber 1, a suction nozzle upper cover 9 combined with the suction nozzle chassis 1, and a host movably connected with the suction nozzle chassis 1 The seat 2 and a height adjustment device; the height adjustment device includes a fixed shaft 3, a swing body 4, a vertical protrusion 6 and a limit sleeve 8.

[0024] The host base 2 has a detachable bottom plate 7, and the bottom of the limit sleeve 8 is connected with the bottom plate 7 by a hook, which is also a detachable connection structure. The bottom plate 7 is also provided with two front caster frames 7a for Install the front casters of the vacuum cleaner, see figure 1 . The swing body 4 is placed in the limit sleeve 8, and its upper part and the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com