Reinforcing method for suspending anchor point of engine and suspending point assembly

An engine mount, fixed point technology, applied in power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problem of unresolved strengthening effect, the effect of strength meeting the requirements, the concentration of force at the mounting point, etc. The effect of shortening the development cycle, increasing the intensity, and saving development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following, the present invention will be further explained in conjunction with the accompanying drawings:

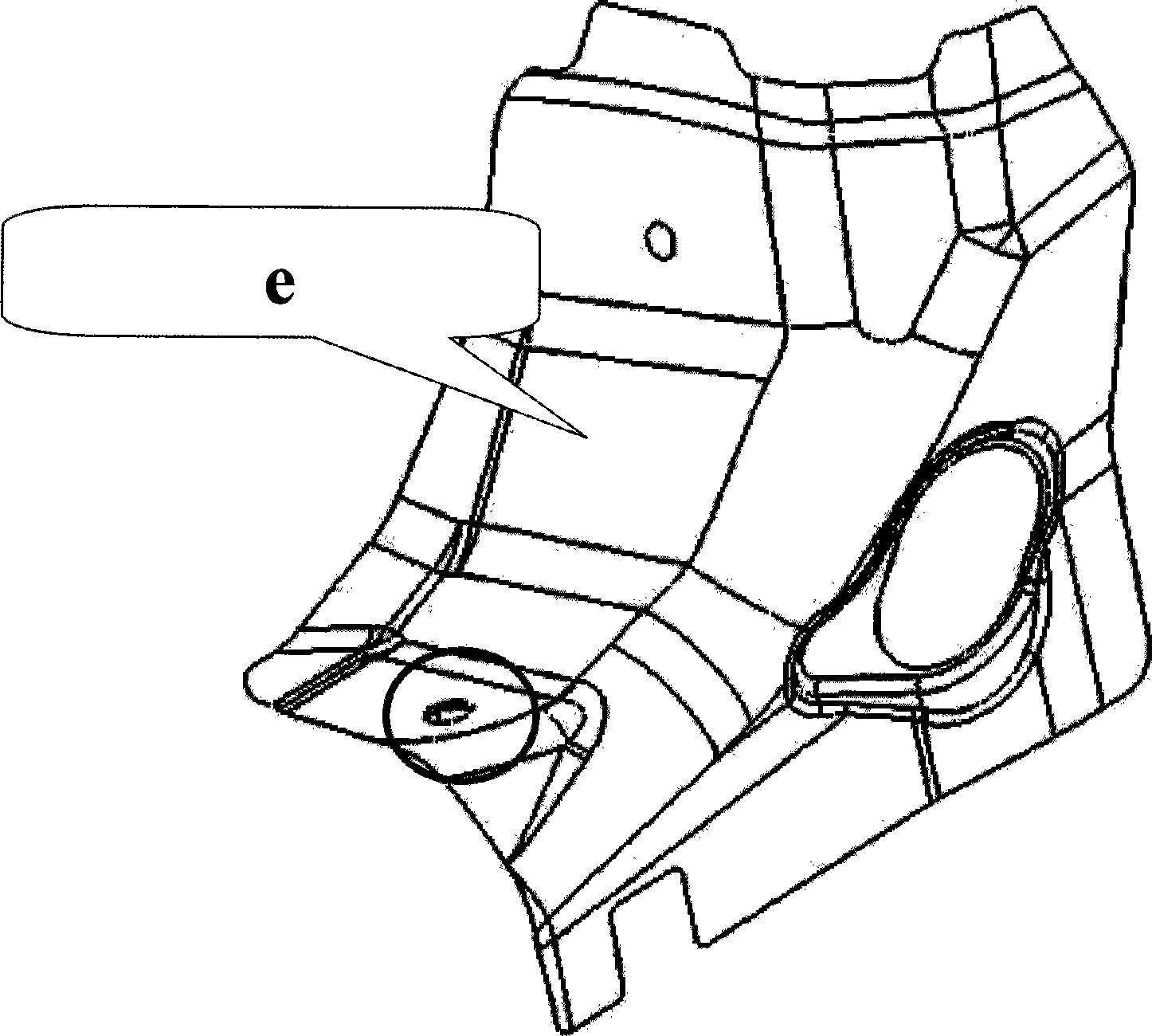

[0055] Such as figure 1 As shown, the traditional way of strengthening the mounting points of the engine wheel cover suspension is only the 100% shape fit of the two layers of sheet metal, which not only increases the difficulty of welding, but also causes the waste of raw materials, and also increases the weight of the car body.

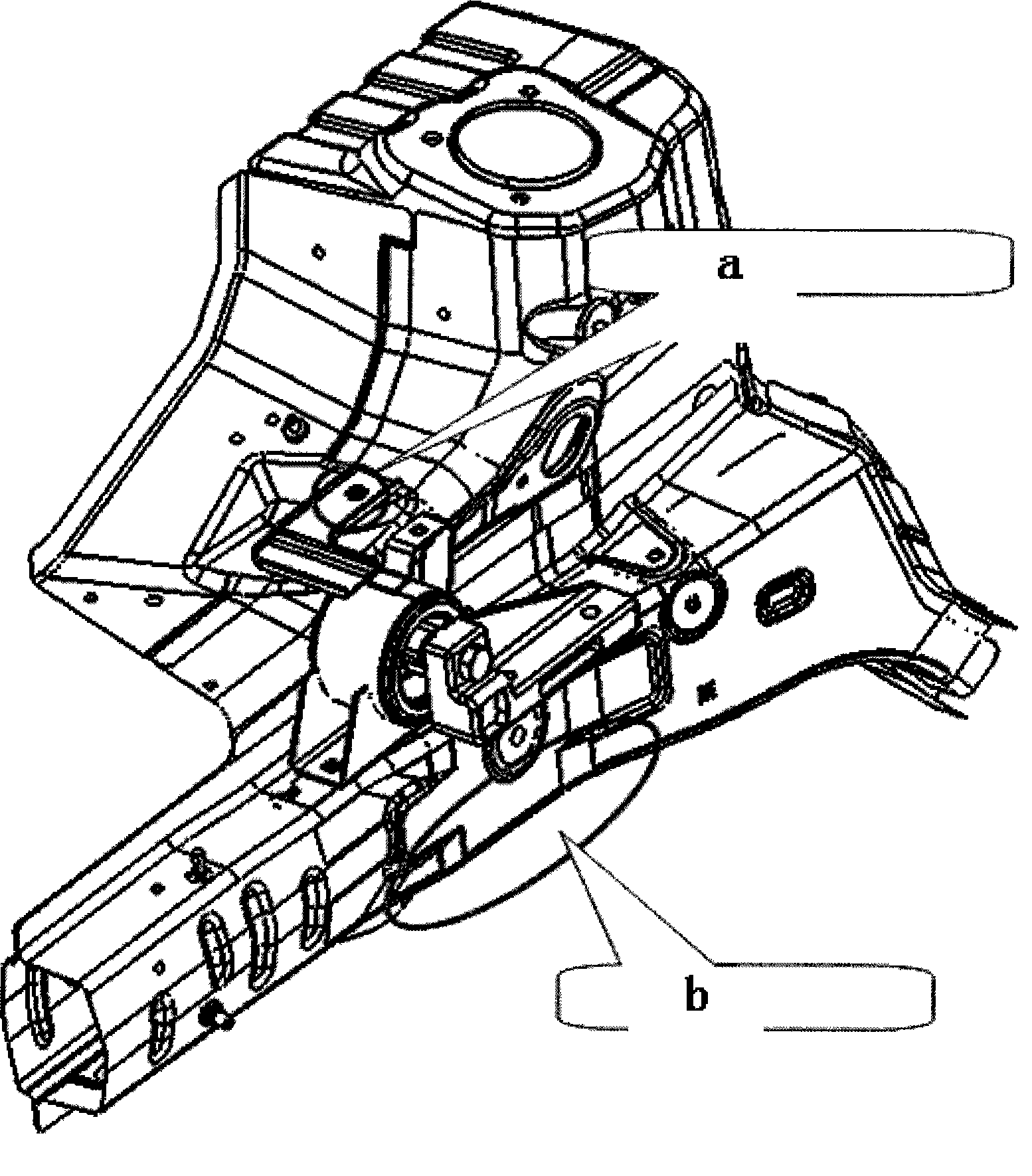

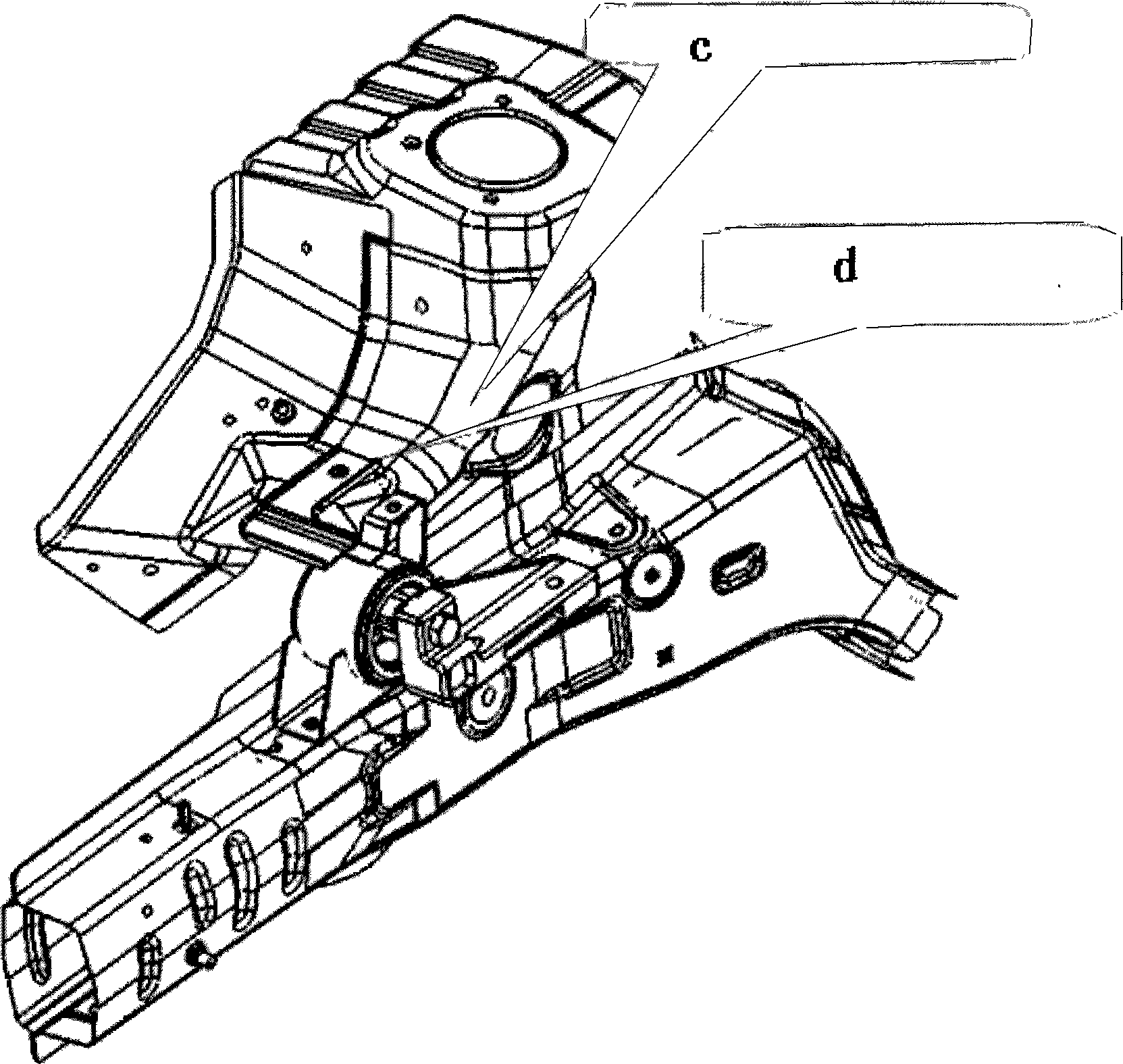

[0056] From Figure 2-3 It can be seen from the above that such a suspension point arrangement can save a lot of space around the front cabin longitudinal beam and also improve the heat dissipation performance of the front cabin.

[0057] Figure 4-10 It can fully demonstrate the advantages of the new wheel cover suspension strengthening method. The invention has a simple structure and compact layout, which effectively improves the strength of the engine wheel cover suspension point, and makes the suspension and the body fixed firml...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap