Frame-type semi-trailer

A semi-trailer and frame-type technology, applied in tractor-trailer combinations, motor vehicles, vehicle parts, etc., can solve the problems of increased total cost, low transportation efficiency, and unusability of semi-trailers, so as to ensure stability and normal use , Improve transportation efficiency, and facilitate operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

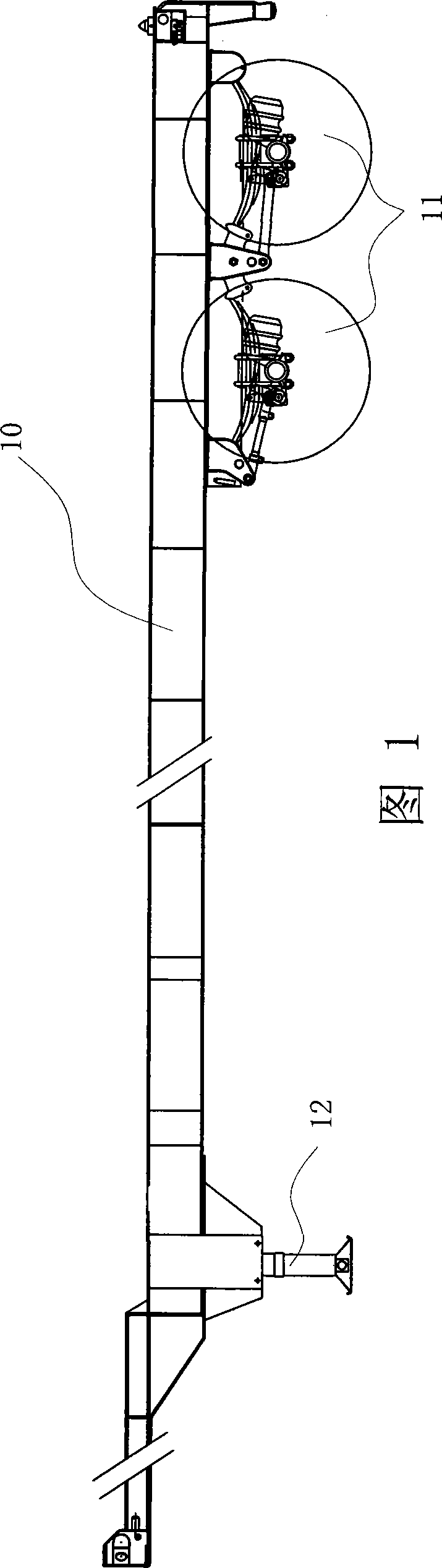

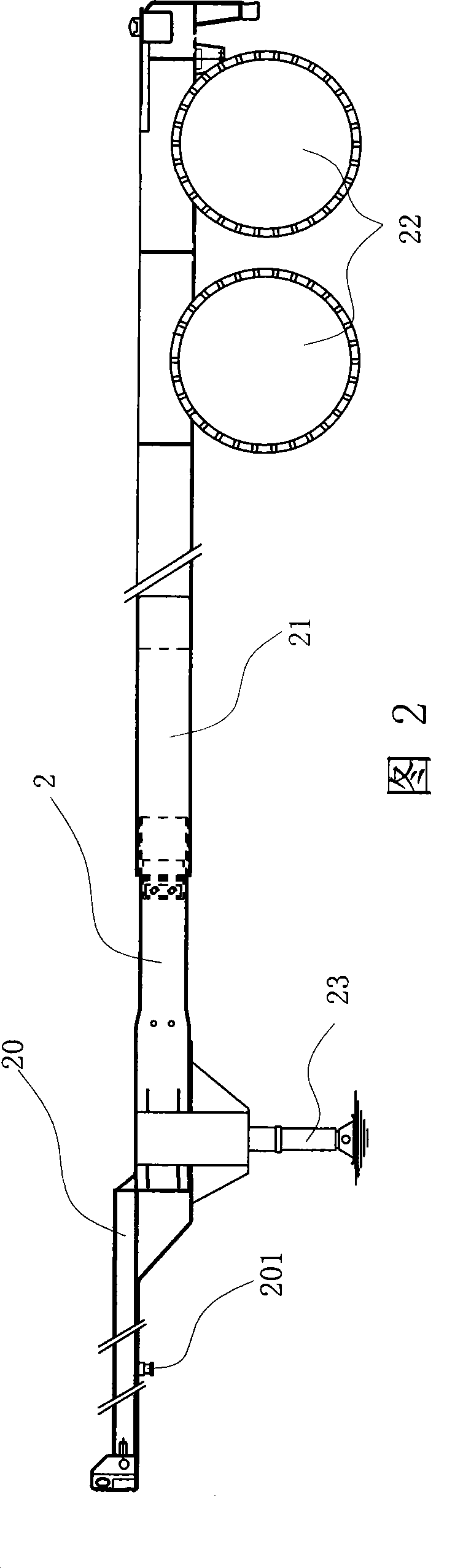

[0035] As shown in Figure 2, a skeleton type semi-trailer 2 includes a gooseneck beam frame 20 located at its front end for connecting with the tractor, a beam frame body 21 for carrying goods, and a frame body 21 arranged on the frame body. The wheel 22 at the lower part of the rear end and the retractable supporting leg 23 arranged at the lower part of the front end of the beam frame body 21 . This car is supported by wheel 22 and retractable support leg 23 when parking, and during use, the traction pin 201 that will be positioned at gooseneck beam frame 20 bottoms is hung in the traction seat of tractor, and contraction support leg 12 gets final product.

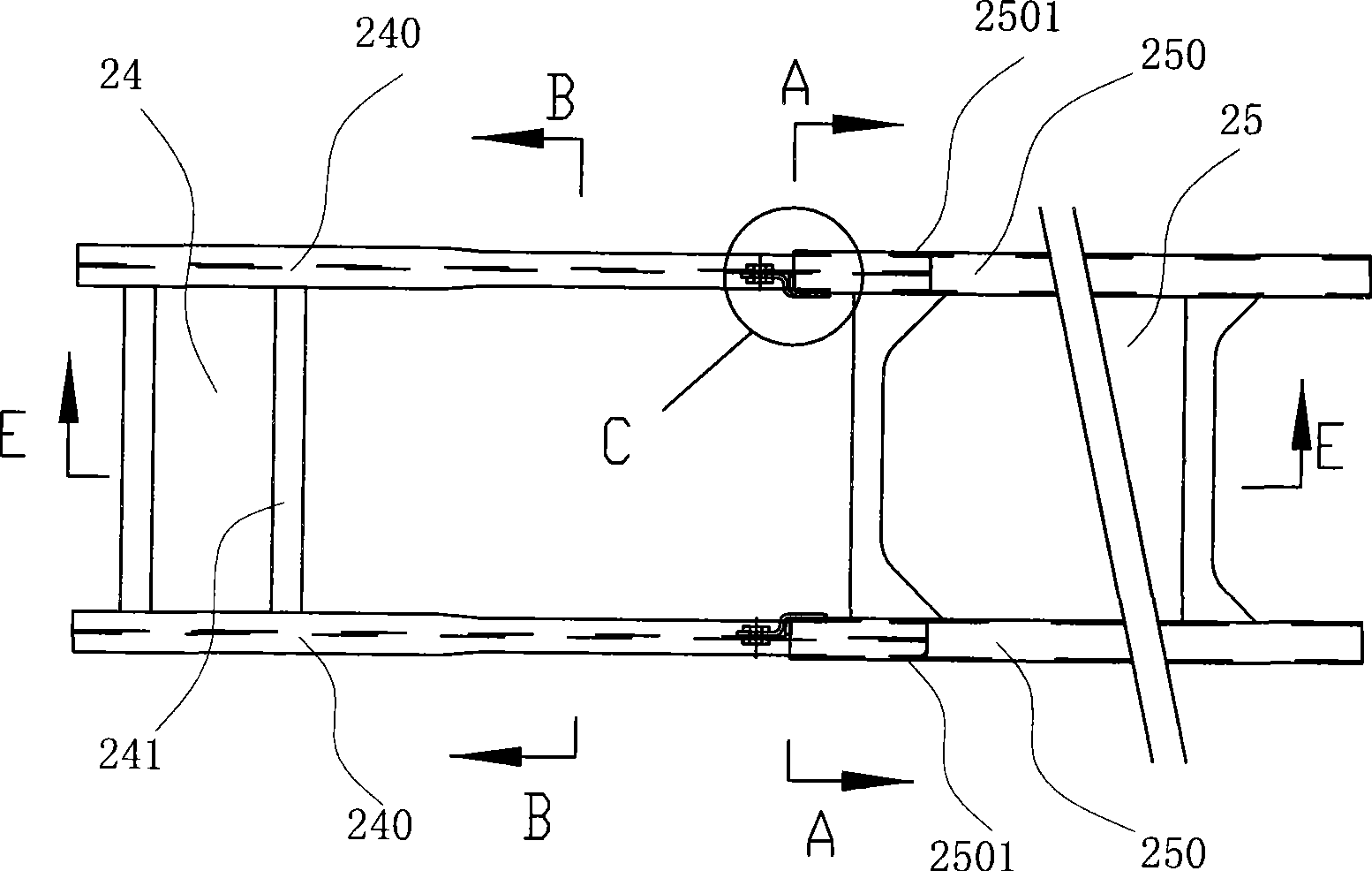

[0036] Such as image 3 The beam frame body 21 shown includes a front beam frame 24 at its front end and a rear end beam frame 25 at its rear end.

[0037] The front beam frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com